Synthesis of Aspirin - EdSpace

advertisement

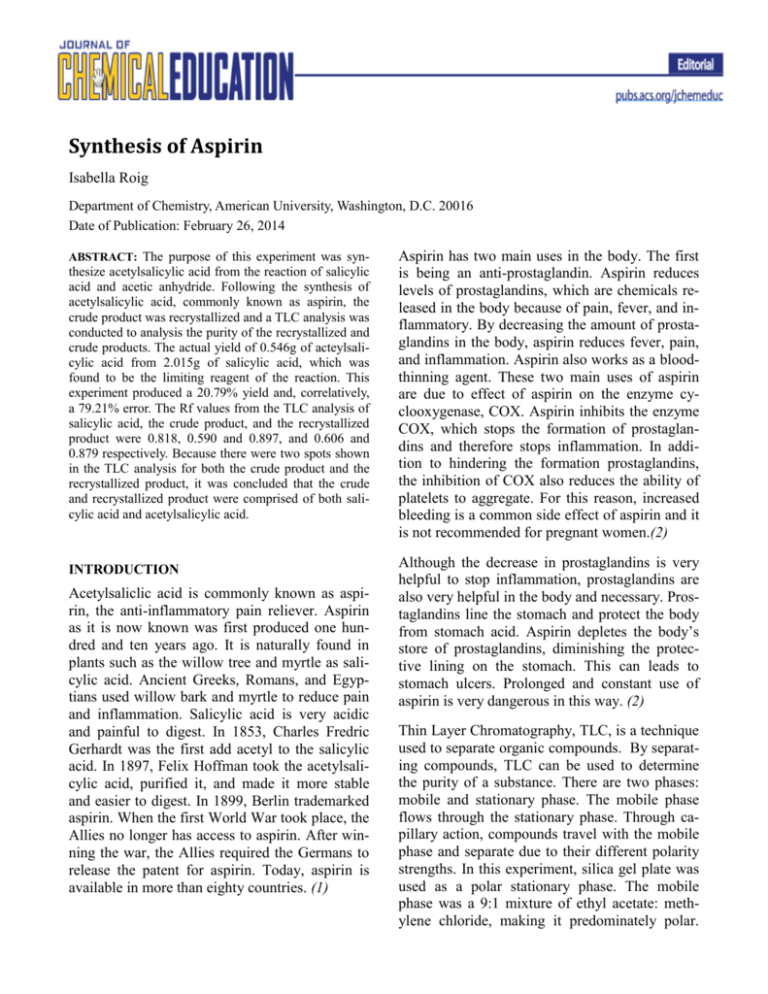

Synthesis of Aspirin Isabella Roig Department of Chemistry, American University, Washington, D.C. 20016 Date of Publication: February 26, 2014 ABSTRACT: The purpose of this experiment was syn- thesize acetylsalicylic acid from the reaction of salicylic acid and acetic anhydride. Following the synthesis of acetylsalicylic acid, commonly known as aspirin, the crude product was recrystallized and a TLC analysis was conducted to analysis the purity of the recrystallized and crude products. The actual yield of 0.546g of acteylsalicylic acid from 2.015g of salicylic acid, which was found to be the limiting reagent of the reaction. This experiment produced a 20.79% yield and, correlatively, a 79.21% error. The Rf values from the TLC analysis of salicylic acid, the crude product, and the recrystallized product were 0.818, 0.590 and 0.897, and 0.606 and 0.879 respectively. Because there were two spots shown in the TLC analysis for both the crude product and the recrystallized product, it was concluded that the crude and recrystallized product were comprised of both salicylic acid and acetylsalicylic acid. INTRODUCTION Acetylsaliclic acid is commonly known as aspirin, the anti-inflammatory pain reliever. Aspirin as it is now known was first produced one hundred and ten years ago. It is naturally found in plants such as the willow tree and myrtle as salicylic acid. Ancient Greeks, Romans, and Egyptians used willow bark and myrtle to reduce pain and inflammation. Salicylic acid is very acidic and painful to digest. In 1853, Charles Fredric Gerhardt was the first add acetyl to the salicylic acid. In 1897, Felix Hoffman took the acetylsalicylic acid, purified it, and made it more stable and easier to digest. In 1899, Berlin trademarked aspirin. When the first World War took place, the Allies no longer has access to aspirin. After winning the war, the Allies required the Germans to release the patent for aspirin. Today, aspirin is available in more than eighty countries. (1) Aspirin has two main uses in the body. The first is being an anti-prostaglandin. Aspirin reduces levels of prostaglandins, which are chemicals released in the body because of pain, fever, and inflammatory. By decreasing the amount of prostaglandins in the body, aspirin reduces fever, pain, and inflammation. Aspirin also works as a bloodthinning agent. These two main uses of aspirin are due to effect of aspirin on the enzyme cyclooxygenase, COX. Aspirin inhibits the enzyme COX, which stops the formation of prostaglandins and therefore stops inflammation. In addition to hindering the formation prostaglandins, the inhibition of COX also reduces the ability of platelets to aggregate. For this reason, increased bleeding is a common side effect of aspirin and it is not recommended for pregnant women.(2) Although the decrease in prostaglandins is very helpful to stop inflammation, prostaglandins are also very helpful in the body and necessary. Prostaglandins line the stomach and protect the body from stomach acid. Aspirin depletes the body’s store of prostaglandins, diminishing the protective lining on the stomach. This can leads to stomach ulcers. Prolonged and constant use of aspirin is very dangerous in this way. (2) Thin Layer Chromatography, TLC, is a technique used to separate organic compounds. By separating compounds, TLC can be used to determine the purity of a substance. There are two phases: mobile and stationary phase. The mobile phase flows through the stationary phase. Through capillary action, compounds travel with the mobile phase and separate due to their different polarity strengths. In this experiment, silica gel plate was used as a polar stationary phase. The mobile phase was a 9:1 mixture of ethyl acetate: methylene chloride, making it predominately polar. Polar stationary phases better absorb polar compounds. Nonpolar compounds will not travel as far along the silica plate as polar compounds. The polarity of a compound is determined by its functional groups. Hydroxyl groups are more polars than esters. Because acetylsalicylic acid has an ester groups and salicylic acid has a hydroxyl group, acetylsalicylic acid will travel farther along the polar silica gel plate. A UV light is used to see the distances the spots of the compounds traveled on the plate. TLC results are expressed in Rf values. Rf is the distance the solute traveled divided by the distance the solvent front.(3) In this experiment, acetyl anhydride and salicylic acid are reacted together while in the presence of phosphoric acid to synthesize acetylsalicylic acid. The mechanism of reaction is displayed in Figure 1 below. Following the synthesis of aspirin, it will be recrystallization as a method of purification. To further test the purification of the recrystallization, a TLC analysis will be conducted to examine the crude product, the recrystallized product, and salicylic acid. Figure 1: Reaction of Aspirin MATERIALS AND METHODS Lab coat Goggles Gloves 50 mL Erlenmeyer Flask 125 mL Erlenmeyer Flask 400 mL Beaker 250 mL Hot Water Bath 250 mL Ice Water Bath Acetic Anhydride Salicylic Acid 85% Phosphoric Acid Distilled Water 10 mL Ethanol 18 mL Ethyl Acetate 2 mL Methylene Chloride 2 Watch Glasses Stirring Rod Vacuum Filter Appartatus 1 110-mm Filter Paper 2 pieces of round Filter Paper Silica Gel Coated TLC Plate Spotting Pipettes UV Light Part 1: Synthesize Aspirin 2.0g of salicylic acid is measured into a 50mL Erlenmeyer flask. 5.0mL of acetic anhydride and 5 drops of 85% phosphoric acid solution were added to the flask. The flask is swirled to rinse any bits of solid that may be on the inner walls of the flask. The 50mL flask is partially submerged in a 70-80°C hot water bath. The mixture is heated for 15 minutes, or until the mixture stopped releasing vapors. The mixture is also occasionally stirred while heating. After 10 minutes in the water bath, 2mL of distilled water is added to the mixture. After 15 minutes of heating in the hot water bath, the mixture is removed from the bath and 20mL of water is added to the flask. The mixture is then cool to near room temperature and transferred to an ice bath for five minutes. Crystals of apririn formed while the mixture cooled. Filter paper was weighed and the mass was recorded to the nerest 0.001g. Vacuum filteration was set up and the mixture was suctioned with the vacuum. When the most of the liquid had been drawn through the funnel, the suction was turned off and the crystals were washed with 5mL of cold, distilled water. After 15 seconds, the suction was turned back on and the crystals were rinsed twice more with 5mL of cold, distilled water. The filter paper and product were transferred to a tared watch glass. The mass of the product on the filter paper was recorded to the nearest 0.001g. Part 2: Purification of Aspirin 0.5g of the crude crystals were set aside for TLC analysis. The remaining crude aspirin was added to a 125mL Erlenmeyer flask. 10mL of hot solvent (ethanol/water) was added to the crude aspirin in a warm water bath until all the crystals were dissolved. The mixture was not boiled. The flask was covered with a watch glass, removed from the warm water bath, and left to cool slowly. When the solution reached room temperature, it was placed in an ice bath to complete cyrstalization. The crystals were vacuum filtered after 10 minutes in the ice bath. The crystals were rinsed with two 3mL portions of ice cold deionized water and one 2mL portion of ice cold ethanol. The crystals were place on a tared watch glass and the mass was recorded. Part 3: TLC Analysis A 400-mL beaker and a watch glass were used as the developing chamber. A piece of 110-mm filter paper was placed at the bottom of the chamber to saturated the chamber with solvent vapors. 20mL of a 9:1 ethyl acetate and methylene chloride mixture was added to the 400mL beaker. In three separate beakers, 3mg of salicylic acid, 3mg of the crude product, and 3mg of the recrystallized product were dissolved in 5-6 drops of the TLC solvent. A horizontal line was lightly marked using a pencil on the silica gel coated TLC plate approximately ½ inch from the bottom. Three even spaced hashes were marked to be the origin points for the spotted compounds. A different spotting pipette was used to spot the TLC plate with the salicylic acid, the crude product, and the recrystallized product on the three hashes. The pipette lightly touched the TLC plate at the hash mark to transfer some of the liquid to the plate. The spots were no larger than about 1/8 of an inch. The plate was placed in the developing chamber and the watch glass was place on top of the beaker. The plate was allowed to develop until the solvent from was approximately ½ inch from the top. The plate was removed and the solvent front was immediately marked. The plate was left to dry before it was examined under the UV light. The spots were circled as they were seen and their centers were marked. The distance the solvent traveled and the distance each spot traveled were recorded. RESULTS Table 1: Synthesis of Aspirin Mass of salicylic acid (g) Volume of acetic anhydride (mL) Mass of acetic anhydride used (g) Mass of filter paper (g) Mass of aspirin and filter paper (g) Mass of aspirin synthesized (g) 2.015 5 5.4 0.132 1.35 0.546 This table shows the data that was collected in this lab. The mass of the aspirin and the filter paper is not equal to the mass of synthesized aspirin plus the mass of the filter paper. This indicates that some aspirin was lost, and not a full yield was collected during the experiment. This is supported by the large percent error calculated below. Table 2: TLC Analysis Compound Distance Solvent Traveled (cm) Distance Spot Traveled (cm) Rf Value Crude Product 3.9 2.3 & 3.5 0.589 & 0.897 Salicylic Acid 3.3 2.7 0.818 Recrystalized Product 3.3 2.0 & 2.9 0.606 & 0.878 The crude and recurstalized products both had two spots on the TLC Plate. This indicates that neither were pure and there was more than one substance in each Calculations: Equation 1: Determining the Limiting Reagent: Molecular Weight of Salicylic Acid:138.12 g/mol (2.015g Salicylic Acid) x (1 mol/ 138.12g) =0.01458 mol Molecular Weight of Acetic Anhydride: 102.09g/mol (5.4g Acetic Anhydride) x (1 mol/ 102.09g) =0.05289 mol Salicylic Acid is the limiting reagent. Equation 2: Theoretical Yield: (0.01458 mol Salicylic Acid) x (1 mol Acetylsalicylic Acid/ 1 mol Salicylic Acid) x (180.16g/ 1 mol Acetylsalicylic Acid)= 2.6267g Acetylsalicylic Acid Equation 3: Percent Yield: Perecent Yield =(Actual Yield/ Theoretical Yield) x 100 (0.546g/ 2.6267g) x 100 = 20.79% Equation 4: Percent Error: Percent Error: ((Actual Yield- Theoretical Yield)/ Theoretical Yield) x 100 (( 0.546-2.6267)/ 2.6267) x 100= 79.21% Equation 5: Rf Value: Rf Value = (Distance Solute Traveled/ Distance Solvent Traveled) Rf (Crude Product, Spot 1)= (2.3cm/ 3.9cm)= 0.590 Rf (Crude Product, Spot 2)= (3.5cm/ 3.9cm)= 0.897 Rf (Salicylic Acid)= (2.7cm/ 3.3cm)= 0.818 Rf (Recrystallized Product, Spot 1)= (2.0cm/ 3.3cm)= 0.606 Rf (Recrystallized Product, Spot 2)= (2.9cm/ 3.3cm)= 0.879 Table 1 displays the raw data from this experiment. This experiment began with 2.015g of salicylic acid and produced a yield of 0.546g of acetylsalicylic acid. Using Equation 1, it was determined that salicylic acid was the limiting reagent. Equation 3 determined that the theoretical yield of 2.6267g of acetylsalicylic acid. Equation 4 calculated the percent yield was 20.79%. The percent error was 79.21%. Table 2 presents the data of the TLC analysis part of the experiment. The Rf values of crude product, salicylic acid, and recrystallized product were 0.590 and 0.897, 0.818, and 0.606 and 0.879 respectively. DISCUSSION Esterification is the reaction of an alcohol or phenol and a carboxyl group in the presence of an acidic catalyst to form a carboxylate ester. The particular esterification process in this experiment of forming acetylsalicylic acid from salicylic acid and acetyl anhydride is also an equilibrium process. (4) Le Chatelier’s principle, which is also known as the equilibrium law, can be used to predict the effect of a change in conditions on an equilibrium process. Temperature, concentration, volume, and pressure are all changes in condition that would cause the equilibrium of the reaction to shift. As the reaction proceeds, the reactants are depleting while the concentration of the products is increasing. It is also stated in the principle that if more of the product were added to the reaction, this would cause the equilibrium to be shift and the creation of more of the reactants. Le Chatelier’s principle can be used to favor the creation of the product of the reaction, aspirin, due to the equilibrium shift caused by the excess acetic anhydride. The principle can also be used to favor the reactants if the necessary conditions were adjusted to convert aspirin to salicylic acid and acetic anhydride. (5) Salicylic acid contains two acidic functional groups: a phenol group and a carboxylic acid. The phenol group of the molecule is very acidic and causing harsh stomach irritation, which therefore makes it difficult to digest. To ease stomach digestion of aspirin, the strength of the acid is reduced by the formation of an ester from the phenol and carboxylic acid.(6) Figure 2: Mechanism of Reaction for the Synthesis of Aspirin purify the crystals. The addition of water separates the crystals from the very water soluble acetic acid. recrystallize the product. The water was added after heating the mixture because the aspirin would not have formed if the acetic anhydride had already reacted with water. Water also aided in nucleophilic substitution at this point in the recrystallization. The following figure details the reaction of water and acetic anhydride. Figure 2 details the reaction occurring between salicylic acid, phosphoric acid, and acetic anhydride. When the phosphoric acid, acting as a catalyst, attacks the carbon oxygen bond (C=O) of the acetic anhydride, it gives it a positive charge. This results in the acetic anhydride being more prone to nucleophilic attacks. Salicylic acid is the nucleophile of this reaction. The partial positive carbon on the acetic anhydride transferred electrons to the oxygen on the phenol group of salicylic acid after it was attacked. This results in the formation of a tetrahedral intermediate. The –OH group, which has an attached electrophilic carbon, forms a double bond between the carbon and oxygen (C=O) by pronating the hydrogen and donating an electron. This loss of a proton reforms phosphoric acid and produces acetylsalicylic acid. Because the synthesis of aspirin is a slow reaction, a catalyst is needed. Phosphoric acid acts as a catalyst to speed up the reaction between Salicylic acid and acetic anhydride. Phosphoric acid is present in the beginning and end of the reaction. Due to its water solubility, it is easily removed by washing the crystals with cold distilled water. The phosphoric acid was used to aid the transfers of hydrogens and electrons. At the end of the reaction, it was recreated in its original state. The reaction was heat at 70-80 degrees Celsius to speed up the reaction of the synthesis. The heating caused the salicylic acid to dissolve more quickly as well as increase in solubility. This is a endothermic synthetisis reaction. Therefore the increase in temperature causes the reaction ot move forwrad, favoring the formation of products.. (6)After heating the mixture for 10-15 minutes, water was added to the crude product to Figure 3: The Reaction Mechanism of Water and Byproducts The crude aspirin is dissolved in a mixture of hot water and ethanol. Water has a polarity of 9. Ethanol has a polarity of 5.2. (7) Of the two solvents, ethanol is the less polar one. Aspirin has a solubility of 10mg/mL in water and a solubility of 50mg/mL in ethanol. Like dissolves like, therefore less polar solvents dissolve less polar solutes. Therefore water and ethanol are great solvents to help purify aspirin. The crude aspirin may not have been clean from the earlier recrystallization due to its contact and exposed with the environment. Pure aspirin was not made in this experiment. The Rf values of crude product, salicylic acid, and recrystallized product were 0.590 and 0.897, 0.818, and 0.606 and 0.879 respectively. Because the crude and recrystallized product showed two spots on the TLC plate, it can be concluded that the crude and recrystallized product were composed of both acetylsalicylic acid and salicylic acid. The spots of the crude and recrystallized product TLC analysis correlate to be either salicylic acid or acetylsalicylic acid. Because the silica was a polar stationary phase, it better absorbs polar compounds. Nonpolar compounds are not as absorbed as polar compounds and therefore more freely along the solvent front, which is polar. Salicylic acid has a hydroxyl functional group. Acetylsalicylic acid has an ester functional group and has a larger mass than salicylic acid. Esthers are not as polar as hydroxyl groups are more polar than esters. Therefore, salicylic acid was more to the silica than the acetylsalicylic acid. This is reflected in the Rf value of 0.818. The acetylsalicylic acid traveled further along the TLC plate than the salicylic acid. From this conclusion, it can be determine that the spot with Rf values of 0.897 in the crude product and 0.879 in the recrystallized product were acetylsalicylic acid. The experiment yielded 0.546g of synthesized aspirin. The theoretical yield for this experiment was 2.6267g. As seen in the results section by use of Equations 3 and 4, the percent yield was 20.79% and the percent error was 79.21%. Because the synthesis of aspirin is an equilibrium process, t is difficult to obtain 100% yield of because a large concentration of the products can cause the reaction to reverse and create the reactants. In addition to this reason, a few errors could have contributed to the low percent yield of this experiment. The percent yield is relatively low because of possible sources of error. Prolonged exposure to the environment and atmospheric air that may have caused air drying. Product could have also been lost while using vacuum filtration. Product may have slipped between the filter top apparatus and the filter paper. Inadequate heating time or high enough temperature may have not allowed for a complete dissolution, resulting in a smaller product yield. CONCLUSION This experiment yielded 0.546g of acetylsalicylic acid. The theoretical yield of this experiment was 2.6267g, given that 2.015g of the limiting reagent, salicylic acid, was used. Respectively, the percent yield and percent was 20.79% and 79.21%. As noted by the small percent yield, much of the product was lost or not successfully synthesized to aspirin. The Rf values of crude product, salicylic acid, and recrystallized product were 0.590 and 0.897, 0.818, and 0.606 and 0.879 respectively. The solvent used as a mobile phase for the TLC analysis was a mixture of ethyl acete and methylene chloride, making it predominately polar. Because the salicylic acid is polar, along with the mobile phase and stationary silica gel phase, it had a lower Rf value than the acetylsalicylic acid as it was absorbed more to the plate. Salicylic acid displayed an Rf value of 0.818, while the two higher spots of the crude and recrystlization product that are presumed to be acteysalicylic acid displayed respective Rf values of 0.897 and 0.879. To prevent further error, the recrystallized product needs to be better purified. To do so the experiment should be more closely and entirely conducted under the fume hood to prevent and decrease exposure to atmospheric air. Also a more temperature controlled hot water bath could also be helpful in better recrystallization, as well as a bit more distilled water to aid in the dissolution of acetic anhydride from the crystals. REFERENCES 1. History of Aspirin; ASPREE: Mansh University, Department of Epidemiology and Preventive Medicine, 2010. http://www.aspree.org/AUS/aspreecontent/aspirin/history-aspirin.aspx (accessed Feb 22, 2014) 2. How Aspirin Works; ASPREE: Mansh University, Department of Epidemiology and Preventive Medicine, 2010. http://www.aspree.org/AUS/aspreecontent/aspirin/how-aspirin-works.aspx (accessed Feb 22, 2014) 3. Williamson, K.; Masters, K. Macroscale and Microscale Organic Experiments, 6th ed.; Cengage Learning: Belmont, 2011 4. Clark, Jim. Esterification; ChemGuide, 2003. http://www.chemguide.co.uk/organicprop s/alcohols/esterification.html (accessed Feb 21, 2014) 5. Le Chatelier’s Principle; Purdue University, Department of Chemistry. http://chemed.chem.purdue.edu/genchem/ topicreview/bp/ch16/lechat.html (accessed Feb 21, 2014) 6. Clark, J. The Effect of Temperature on Reaction Rate. Chemguide, Oct. 2013, n.p. http://www.chemguide.co.uk/physical/bas icrates/temperature.html (accessed Feb 21, 2014). 7. Bayers, John A. Polarity Index; Chemical Ecology, 2003. http://www.chemicalecology.net/java/solvents.htm (accessed Feb 21, 2014). ACKNOWLEDGMENTS The author would like to acknowledge the Americam University Chemistry Department as well as Dr. Dehghan and TA, Karlena Brown and the students who participated in the experiment. Acknowlegement is also extended to those mentioned in the References section of this paper. This assignment is my own work and I have cited all material used in its preparation. This assignment has not previously been submitted at any other time or any other course. I have not copied in part or whole the work of other students or person. SIGNATURE____________________________ DATE__________________________________ 8