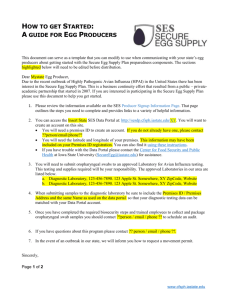

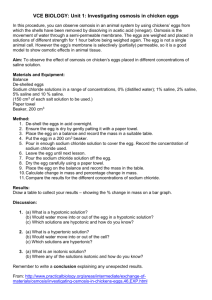

Food Safety Program Template - Shell Egg Program Egg Production

advertisement