Inspections

advertisement

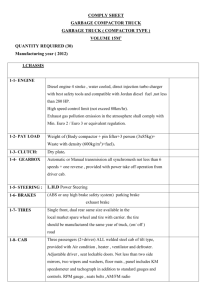

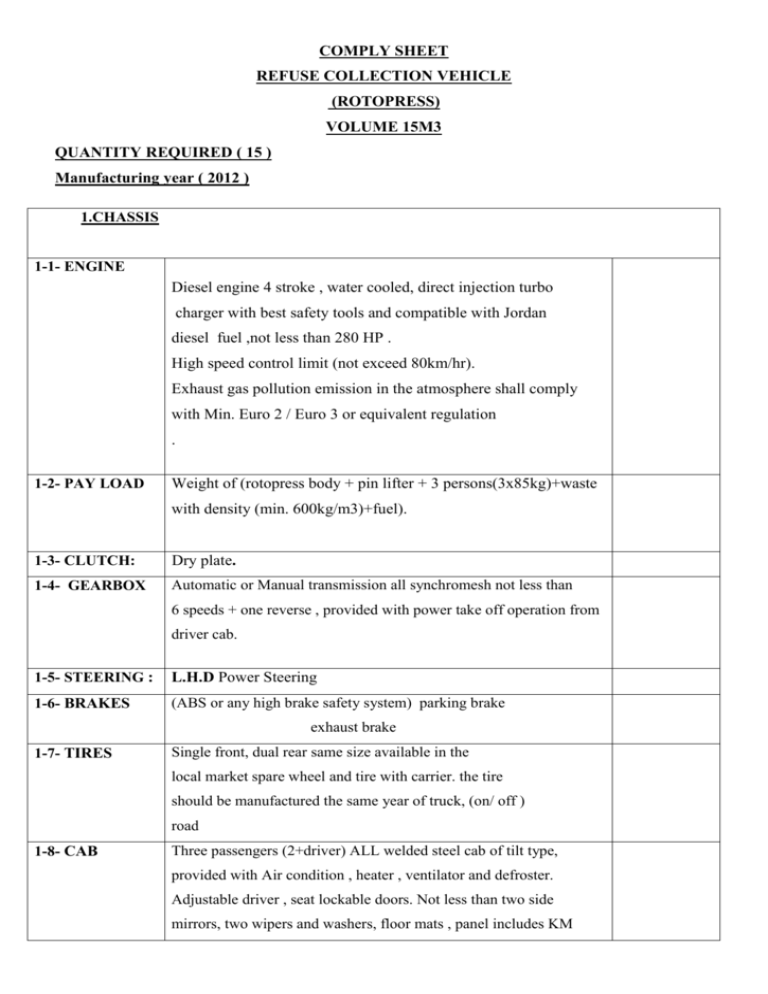

COMPLY SHEET REFUSE COLLECTION VEHICLE (ROTOPRESS) VOLUME 15M3 QUANTITY REQUIRED ( 15 ) Manufacturing year ( 2012 ) 1.CHASSIS 1-1- ENGINE Diesel engine 4 stroke , water cooled, direct injection turbo charger with best safety tools and compatible with Jordan diesel fuel ,not less than 280 HP . High speed control limit (not exceed 80km/hr). Exhaust gas pollution emission in the atmosphere shall comply with Min. Euro 2 / Euro 3 or equivalent regulation . 1-2- PAY LOAD Weight of (rotopress body + pin lifter + 3 persons(3x85kg)+waste with density (min. 600kg/m3)+fuel). 1-3- CLUTCH: Dry plate. 1-4- GEARBOX Automatic or Manual transmission all synchromesh not less than 6 speeds + one reverse , provided with power take off operation from driver cab. 1-5- STEERING : L.H.D Power Steering 1-6- BRAKES (ABS or any high brake safety system) parking brake exhaust brake 1-7- TIRES Single front, dual rear same size available in the local market spare wheel and tire with carrier. the tire should be manufactured the same year of truck, (on/ off ) road 1-8- CAB Three passengers (2+driver) ALL welded steel cab of tilt type, provided with Air condition , heater , ventilator and defroster. Adjustable driver , seat lockable doors. Not less than two side mirrors, two wipers and washers, floor mats , panel includes KM COMPLY SHEET REFUSE COLLECTION VEHICLE (ROTOPRESS) VOLUME 15M3 QUANTITY REQUIRED ( 15 ) Manufacturing year ( 2012 ) speedometer and tachograph in addition to standard gauges and controls. RPM gauge , seats belts ,AM/FM radio 2.BODY AND 2.1 Suitable and high efficiency system. COMPACTION 2.2 Net capacity 15m3. SYSTEM 2.3 Foldable footboards built in anti-skidding plate. 2.4 Dimension and thickness of material should be compatible with the required compaction ratio using high corrosion resistance material. 2.5 Compaction ratio not less than 6 :1 . 2.6 Work cycle time (30-35) seconds. 2.7 Painting : Sand Blasting: 2.7.1 One coat of anti – corrosion primer. 2.7.2 At least two coats paint. 2.8 Rear camera connected to cabinet screen device and movement safety. 2.9 Self-lubricating system 3.HYDRAULIC 3.1 Suitable system for hydraulic pump & motor. AND 3.2 Full automatic control integrated with lifting device (one ELECTRICAL SYSTEM button bush). 3.3 Safety hard and soft ware for : 3.3.1 Two hydraulic cylinders for lifting / lowering tailgate. 3.3.2 Provided with load devise for stop rotopress when load approach 8 ton. 3.3.3 Lifting and tipping device type with two folding arms and frame. COMPLY SHEET REFUSE COLLECTION VEHICLE (ROTOPRESS) VOLUME 15M3 QUANTITY REQUIRED ( 15 ) Manufacturing year ( 2012 ) 3.3.4 Hydraulic oil over heat safety limit. 3.3.5 Low hydraulic oil level (safety switch off). 3.3.6 Oil filtering (cartridge & magnetic). 3.3.7 High quality of all hydraulic components . 3.3.8 All hydraulic system should be equipped with high level of safety protection. 3.4 (12-24)-volt electric system, starter, alternator, batteries in series headlights instruments …etc system , 2 beacon . 3.5 Separate manual control of the packer and carriage plate functions 4.GRADEABILITY 4.1-Not less than 35 % with full load during using lifting device (stop/startup). 5.LIFTING SYSTEM 5.1 High capacity articulated arm lifting device works in min. two stages by four double effects hydraulic cylinders to ensure lifting and lowering of containers smoothly. 5.2 Can lift standard 120/240/770 and 1100 liter containers. 5.3 Lifting weight capacity not less than 800 kg. 6.ACCESSORIES 6.1 Service manual and spare parts catalogue. For each unit. 6.2 Years of Manufacture: (2012 ) for both chassis and rotopress, brand new products. 6.3 Complete tool kit for preventive maintenance, fire extinguisher ( 10kg ) 6.4 Hydraulic jack 10 ton . 6.5 Attached spare parts list, priced individually. 6.6 COLOR: Orange / White. 6.7 All specification must be highlighted on catalogue when submitting the bid offer. COMPLY SHEET REFUSE COLLECTION VEHICLE (ROTOPRESS) VOLUME 15M3 QUANTITY REQUIRED ( 15 ) Manufacturing year ( 2012 ) 6.8 Comply sheet for the specifications mentioned above should be provided 7.TRAINING 7.1 Technical training course for three technical employer in manufactory country after final receiving 8.1 GENERAL Required Brand new vehicles model (2012 ) will be used in Jordan and should be suitable with high performance in all Jordanian geographic areas and at all weather conditions as example: 8.1.1 Temperature range : from -10 C to + 50 C 8.1.2 Altitude : from (-400) meter (below sea level) up to (+1200) meter (above sea level), humid in some areas and dry in others, dusty weather , desert , and cloudy weather are available. 8.1.3 Roads : Asphalt highways between cities , climbing and descending mountain's roads. 8.1.3.1 Secondary asphalt narrow roads between towns and villages, second and 3'rd class quality. 8.1.3.2 Agricultural un asphalted roads between small villages. 8.1.4 Duration of daily job: Between 16 to 24 hours, i.e. (two – three) shifts. COMPLY SHEET REFUSE COLLECTION VEHICLE (ROTOPRESS) VOLUME 15M3 QUANTITY REQUIRED ( 15 ) Manufacturing year ( 2012 ) 8.1.5 Type of refuse : All types: solid, soft, dry, damped, heavy and light refuse (not separated refuse) …etc. 8.1.6 Required vehicles shall comply all Jordanian traffic regulations and laws as examples: 8.1.6.1 Max. axle loads – front and Rear – single and dual tires. 8.1.6.2 Max. width, height and length. 8.1.6.3 All lights, signals, wind shields, mud flaps, reverse alarm, horn, mirror and sun visors….etc. 8.1.6.4 Left hand drive. 8.1.6.5 Drivers tools and extinguisher. 8.1.6.6 License plate front and rear. 8.1.7 A prices list of spare parts would be required for three years of operation. 8.1.8 Bidder shall specify all required information of conditions and of specification with limited and clear information one by one consequently and respectively. 8.1.9 Warranty against any defect caused by manufacturing reasons for all the vehicle including chassis and refuse (compactor/rotopress), lifting and lowering device, and all other components a warranty for the tires, batteries as provided by manufacturer. 8.1.10 The required vehicles should be subjected to actual real run test at site before the final report of receipt. 8.1.11 Bidder shall submit a certificate from the (rotopress's) manufacturer or agent, stating that the COMPLY SHEET REFUSE COLLECTION VEHICLE (ROTOPRESS) VOLUME 15M3 QUANTITY REQUIRED ( 15 ) Manufacturing year ( 2012 ) manufacturer has no objection concerning installing his (rotopress) on the Chassis provided by the bidder without any reservation . Also Bidder shall submit a certificate from the chassis' Manufacturer or agent, stating that the Manufacturer has no objection concerning installing the (rotopress) on his chassis provided by bidder without any reservation. 8.9 Inspections: 8.9.1 Third party Inspection: Supplier Shall arrange with recognized 3rd party inspection body before shipping in the country of origin for both chassis and (rotopress), cost shall be born by the supplier. 8.9.2 Maximum three persons from the owner side have to witness the testing and inspection process for the production. 8.9.3 Final inspection : (Final Acceptance): The Technical Committee assigned by owner will examine the (garbage truck) against the Technical Specifications, fuel consumption, and Contract Documents. جهاز خلفي) و تشمل قطع الغيار+ الكفالة لمدة ثالثة سنوات لأللية كاملة (شاصي على ان يتم تقديم القطع، المستهلكة من بريك و كالتش وغيار زيت وفالتر مجانا ً وأجور المستهلكة جميعها في العرض المقدم من الشركة وحسب كتالوجات الشركة الصانعة للجهاز الكاوتشوك و البطاريات حسب, ساعة يوميا16 والشاصي وعلى اساس اعتماد عمل االلية . توصيات الشركة الصانعة