polb23897-sup-0001

advertisement

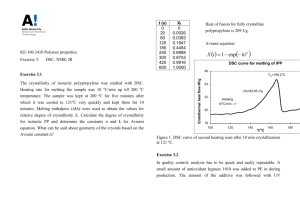

Supporting Information Nucleation, crystallization and thermal fractionation of poly(‒caprolactone)‒grafted‒lignin: Effect of the grafted chains length and lignin content. Ricardo A. Pérez–Camargo1-2, Guery Saenz2, Stéphanie Laurichesse3, María Teresa Casas4, Jordi Puiggalí4, Luc Avérous3 and Alejandro J. Müller1,2,5 (a) 15 PCL2 PCL3 PCL 63.3 127 PCL 0 44 Heat flow endo up (W/g) PCL (b) PCL 15 PCL2 PCL3 PCL 44 63.3 127 149 10 20 30 40 Temperature (°C) 50 4.0 W/g 5.0 W/g Heat flow endo up (W/g) Standard DSC Scans PCL 149 10 20 30 40 50 60 70 80 Temperature (°C) (c) 25 PCL10 16.7 PCL17 20 PCL18 13.7 Heat flow endo up (W/g) Heat flow endo up (W/g) 24.4 PCL6 11.9 PCL37 0 10 20 30 40 PCL6 50 Temperature (°C) 24.4 25 PCL10 16.7 PCL17 20 PCL18 PCL29 10 W/g 10 W/g PCL29 (d) 13.7 11.9 PCL37 10 20 30 40 50 60 70 80 Temperature (°C) Figure S1. DSC cooling and subsequent heating scans at 20°C/min for (a), (b) neat PCLs and PCL–g–lignin copolymers with 2 and 3 wt% of lignin content respectively and (c), (d) PCL–g–lignin copolymers with lignin contents higher than 3 wt%. The plots are normalized by PCL weight fraction. The red curves are for neat PCLs and the blue curves for PCL–g–lignin copolymers. Avrami Fit The Avrami Fit was performed using an Origin® software application called Polymer Crystallization Plugin. This Origin® plugin was developed by Lorenzo et al.1, and can be used not only to perform Avrami Fits but also to perform Lauritzen‒Hoffman Crystallization Fits. The Plugin is offered free upon request to Prof. A.J. Müller. The data obtained by isothermal Differential Scanning Calorimetry (DSC) tests were used to perform the Avrami Fits and the graphical comparisons between the experimental data and the predictions of the theory. Firstly, it allows the baseline to be established and later calculate the integral of the calorimetric isothermal curve. Secondly, the linear fit according to the Avrami equation and fitting errors can be performed. Vc (relative volume fraction crystallinity) is calculated according to Ec. 1, whereas 𝑉𝑐 range is selected from 0.03 to 0.20 in order to obtain the best fit within the primary crystallization range. 𝑉𝑐 = 𝑊𝑐 𝜌𝑐 𝑊𝑐 + 𝜌 (1 − 𝑊𝑐 ) 𝑎 (1) 𝜌𝑐 and 𝜌𝑎 are the fully crystalline and fully amorphous polymer densities, respectively. For all calculations, 𝜌𝑐 = 1.200 and 𝜌𝑐 = 1.090 g/cm3 were used for PCL. The relative crystalline mass fraction 𝑊𝑐 is calculated as: 𝑊𝑐 = ∆𝐻(𝑡) ∆𝐻𝑡𝑜𝑡𝑎𝑙 (2) where ∆𝐻(𝑡) and ∆𝐻𝑡𝑜𝑡𝑎𝑙 are the enthalpy as a function of crystallization time and the maximum enthalpy after completion of the crystallization process. (Hf)theoretical (Hf)experimental (H.Flow)theoretical (H.Flow)experimental Heat Flow Endo Up (mW) (a) (b) 1.0 Hm(norm) 0.8 0.6 0.4 0.2 50% 0 1 2 3 50% 0.0 4 t-t0 (min) 5 6 0 1 2 3 4 5 Time (min) 6 7 (1-Vc)theoretical (1-Vc)experimental 1 (c) 1.0 Log(-ln(1-Vc)) 0.8 1-Vc 0.6 (d) 0 -1 0.4 0.2 -2 50% 0.0 -1 0 -3 1 -0.5 0.0 0.5 Log(t-to) Log (t-to) Figure S2. Avrami plots obtained by the Origin® plugin developed by Lorenzo et al. (a) Experimental DSC crystallization isotherm of PCL15 at 31ºC and its fitting with the Avrami equation. The experimental crystallization half–time is indicated. (b) Relative enthalpy of crystallization (Ec. 2) as a function of time. (c) Evolution of the normalized volumetric fraction of the amorphous phase as a function of crystallization time. (d) Linear fitting of the Avrami equation in the primary crystallization range, where the slope indicates the Avrami index and the intercept the overall crystallization rate constant. Finally, the Avrami equation is rearranged as follows: log[− ln[1 − 𝑉𝑐 (𝑡 − 𝑡0 )]] = log(𝐾) + 𝑛 log(𝑡 − 𝑡0 ) (3) where n is the Avrami index and K is the overall crystallization rate constant. The experimental and predicted half‒crystallization time 𝜏50% can be also determined by this Origin® plugin. According to the Avrami equation, 𝜏50% is: 1⁄ 𝑛 𝜏50% ln[1 − 𝑉𝑐 ] = [− ] 𝐾 (4) Then, depending on the goodness of the fit (up to 50% conversion) there may be a difference between the experimental and predicted values of 𝜏50%. The parameters obtained by Avrami Fits are collected in Table S1 (samples of neat PCLs), Table S2 (samples with low lignin content), Table S3 (samples with intermediate lignin content) and Table S4 (samples with high lignin content). 44 PCL3 PCL10 25 PCL17 PCL29 13.7 PCL2 15 127 PCL PCL 149 PCL 63.3 PCL37 16.7 24.4 PCL6 PCL18 20 11.9 (a) (b) 2 10 -1 n n 10 -1 K (min ) -1 K (min ) 10 -8 25 30 35 40 Tc (ºC) 45 50 10 -11 20 30 40 50 Tc (ºC) Figure S3. Kn values as a function of Tc for (a) neat PCLs and (b) PCL–g–Lignin. Figure S3 shows the Kn values obtained at different Tc for (a) neat PCLs and (b) PCL‒g‒lignin. The trends exhibited in Figure S3 are in line (as expected) with the trends exhibited by 1/50% versus Tc, since both Kn and 1/50% represent a measurement of the overall crystallization rates. 127 PCL 16.7 PCL3 63.3 PCL18 PCL6 20 24.4 PCL29 PCL10 13.7 25 PCL37 4 (a) 3 11.9 (b) 3 2 1 0 20 44 PCL17 Avrami Index (n) Avrami Index (n) 4 PCL2 149 PCL 15 PCL 25 30 35 40 Tc (°C) 45 50 2 1 0 20 25 30 35 40 45 50 Tc (°C) Figure S4. Avrami index values for: (a) neat PCLs and (b) PCL–g–lignin samples. Figure S4 shows the Avrami Indexes for neat PCLs (see Fig. S4(a)) and PCL–g–lignin samples (see Fig. S4 (b)) as a function of the crystallization temperature. Table S1. Parameters obtained by fitting the Avrami theory to neat PCLs PCL127 Tc (°C) n 26 27 28 29 30 31 32 33 37 38 39 40 41 42 43 44 ----------------1.9 2.0 2.1 2.1 2.2 2.1 2.3 2.3 K×103 min–n ----------------242.4 151.0 88.3 47.7 27.0 15.9 5.9 2.5 τ1/2t min ----------------1.75 2.17 2.72 3.49 4.49 5.80 8.25 11.1 PCL15 τ1/2e min ----------------1.60 2.02 2.58 3.38 4.40 5.72 8.23 11.1 R2 n ----------------0.9993 0.9995 0.9998 0.9999 1.0000 1.0000 1.0000 1.0000 2.3 2.3 2.3 2.3 2.5 2.8 3.1 3.0 ----------------- K×103 min–n 77530 37317 1801 5365 978.2 160.7 32.5 10.8 ----------------- τ1/2t min 0.13 0.18 0.25 0.42 0.87 1.67 2.71 4.1 ----------------- PCL149 τ1/2e min 0.15 0.20 0.25 0.42 0.87 1.67 2.75 4.1 ----------------- R2 n 1.0000 1.0000 0.9999 0.9999 0.9997 0.9998 0.9999 1.0000 ----------------- ----------------1.9 2.0 2.2 2.3 2.3 2.3 2.3 2.3 K×103 min–n ----------------815.4 570.7 331.8 179.3 92.7 45.0 19.8 9.8 τ1/2t min ----------------0.92 1.10 1.41 1.81 2.38 3.28 4.62 6.4 τ1/2e min ----------------1.02 1.22 1.57 2.02 2.60 3.53 4.83 6.6 R2 ----------------0.9997 0.9998 0.9997 0.9996 0.9998 0.9998 1.0000 1.0000 Table S2. Parameters obtained by fitting the Avrami theory to low PCL-g-lignin samples. PCL624.4 Tc (°C) n 34 35 36 37 38 39 40 41 42 43 44 45 46 2.6 2.8 3.1 3.2 3.5 3.5 3.1 3.2 ----------- K×103 min–n 4643 2627 1143 454 143 31 22 4.5 ----------- τ1/2t min 0.48 0.62 0.85 1.14 1.58 2.45 3.04 4.81 ----------- PCL244 τ1/2e min 0.47 0.60 0.85 1.13 1.58 2.43 3.02 4.78 ----------- R2 n 0.9995 0.9995 0.9997 0.9998 0.9999 0.9999 0.9998 0.9999 ----------- ----------2.5 2.7 2.9 2.9 2.9 2.8 2.7 2.5 K×103 min–n ----------1809 790 260 120 40 14 5 3 τ1/2t min ----------0.7 1.0 1.4 1.8 2.7 4.0 6.2 9.3 PCL363.3 τ1/2e min ----------0.7 0.9 1.4 1.8 2.6 3.9 6.0 9.0 R2 n ----------0.99954 0.99955 0.99966 0.9998 0.99978 0.9998 0.99977 0.99977 ----------2.4 2.7 3.0 2.6 3.3 2.7 2.7 2.8 K×103 min–n ----------1606 679 216 127 12 10 1.6 0.21 τ1/2t min ----------0.71 1.01 1.48 1.92 3.41 5.01 9.32 18.1 τ1/2e min ----------0.70 1.00 1.50 1.90 3.50 4.98 9.22 17.8 R2 ----------0.9999 1.0000 1.0000 1.0000 0.9999 1.0000 1.0000 1.0000 Table S3. Parameters obtained by fitting the Avrami theory to intermediate PCL-g-lignin samples. PCL1820 Tc (°C) n 28 29 30 31 32 33 34 35 36 37 38 39 40 41 --2.2 2.3 2.6 3.1 3.2 3.2 3.1 3.0 3.1 2.7 ------- K×103 min–n --7491.0 3044.5 780.7 127.9 45.9 18.8 9.1 3.3 0.69 0.93 ------- τ1/2t min --0.34 0.52 0.95 1.74 2.32 3.09 4.13 6.0 9.4 12.0 ------- PCL1716.7 τ1/2e min --0.37 0.53 0.97 1.75 2.33 3.10 4.12 5.9 9.3 12.1 ------- R2 n --1.0000 0.9999 0.9999 0.9999 0.9999 0.9999 0.9998 0.9999 1.000 1.000 ------- 2.4 2.5 2.6 2.9 2.9 2.9 2.9 2.7 ------------- K×103 min–n 8552 3202 1065 259 86 39 16 8 ------------- τ1/2t min 0.35 0.54 0.85 1.40 2.06 2.72 3.72 5.20 ------------- PCL1025 τ1/2e min 0.38 0.58 0.87 1.42 2.03 2.67 3.65 5.08 ------------- R2 n 0.99999 0.99999 0.99989 0.99988 0.99981 0.99984 0.99984 0.99983 ------------- ------------3.3 3.4 3.5 3.4 3.5 3.1 2.7 2.4 K×103 min–n ------------604 230 74 22 4.2 1.9 1.5 0.72 τ1/2t min ------------1.04 1.38 1.91 2.73 4.28 6.54 9.97 17.47 τ1/2e min ------------1.00 1.33 1.83 2.62 4.10 6.15 9.13 15.92 R2 ------------0.9990 0.9992 0.9992 0.9991 0.9991 0.9990 0.9992 0.9995 Table S4. Parameters obtained by fitting the Avrami theory to high PCL-g-lignin samples. PCL3711.9 Tc (°C) n 21 22 23 24 25 26 27 28 29 30 31 32 2.1 2.2 2.1 2.2 2.2 2.1 2.3 ----------- K×103 min–n 621 454 329 155 73 43 10 ----------- τ1/2t min 1.05 1.21 1.42 1.99 2.74 3.82 6.46 ----------- PCL2913.7 τ1/2e min 1.15 1.32 1.50 2.15 2.95 4.17 6.85 ----------- R2 n 0.99994 0.99993 0.99998 0.99993 0.99988 0.99995 0.99996 ----------- --------2.7 2.8 2.7 2.5 3.5 3.2 3.3 2.9 K×103 min–n --------9999 2581 942 323 30 17 3 4 τ1/2t min --------0.37 0.63 0.89 1.36 2.46 3.21 5.00 5.88 τ1/2e min --------0.40 0.70 0.92 1.35 2.52 3.28 4.98 5.80 R2 --------0.99997 0.99993 1.0000 0.99987 0.99999 1.0000 0.99949 0.99997 References 1. A. T. Lorenzo, M. L. Arnal, J. Albuerne, A. J. Müller, Polymer Testing 2007, 26, 222–231.