Company Datasheet

advertisement

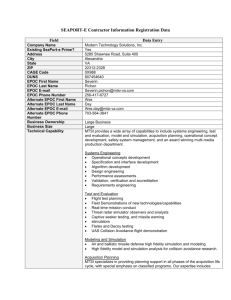

SEAPORT-E Contractor Information Registration Data Field Company Name Existing SeaPort-e Prime? Address City State ZIP CAGE Code DUNS EPOC First Name EPOC Last Name EPOC E-mail EPOC Phone Number Alternate EPOC First Name Alternate EPOC Last Name Alternate EPOC E-mail Alternate EPOC Phone Number Business Ownership Business Size Technical Capability Data Entry Manufacturing Techniques, Inc. (MTEQ) Yes, US Navy SeaPort-e, N00178-06-D-4822 140 Technology Park Drive Kilmarnock VA 22482-3837 1TAV2 806951570 Clara Schuster cschuster@mteq.com 540-658-2720 x 1424 Bryan Schuster bschuster@mteq.com 540-658-2720 x 1428 Large Business, ( C ) 101-250, Over $17 million MTEQ provides world-class design, development, and production facilities to ensure quality development for our customers with three major facilities. MTEQ’s technical staff covers all disciplines required for design, development, test, and transition to production, including mechanical, electrical, optical, and software engineering. The engineers are equipped with industry standard design tools such as SolidWorks & Pro-E for mechanical design, Zemax & KDP for optical design, ORCAD for electronics layouts, OPTIKS & ENVI for hyperspectral evaluation, NVTHERM for night vision range performance modeling, and utility software such as MATLAB and LABVIEW for mathematical modeling and test automation. MTEQ’s Sensor Products & Development Division which operates within a 4,200 sq ft location in Stafford, VA and houses several optics and electronics Laboratories as well as the corporate engineering center. The facilities enable development prototype sensors for various DoD applications and in-house R&D product development. The engineering group uses a Dimension 3D printer for making plastic solid models and parts with feature dimensions up to 12″. The labs contain a variety of test and assembly equipment including laminar flow hoods with HEPA filters, a lens MTF measuring station, infrared collimated target projectors, blackbody sources, optical assembly and cleaning equipment, electronics breadboarding, acoustic measuring instruments, electronics test benches, various gauges, and related mechanical measuring devices. MTEQ possesses the ability to manufacture printed circuit boards (PCB's) and electronic assemblies in an ISO 9001: 2008 and AS9100C certified, 26,000 ft2 Rapid Prototyping & Production Facility located in Kilmarnock, VA. MTEQ’s Rapid Prototyping & Production Facility sits on a five acre campus and supports a wide range of fabrication capabilities from printed circuit boards, cables, box assemblies, to complex sensor systems. The large warehouse Field Tasking Functional Area(s) Subcontracting Goal Impact Past Performance Data Entry facilities and multiple loading bays also support vehicle integration efforts. Design, development, modification, procurement, manufacture, procurement, testing, and fielding support. The MTEQ technical staff covers all disciplines required for design, development, test, and transition to production, including mechanical, electrical, optical, and software engineering. MTEQ is fully capable of providing materials and services for the development, prototyping, and evaluation and fielding support for this effort. MTEQ follows a standard lifecycle process model that is scaled to each individual project. This model can be applied to any stage of program effort, from Prototype Design & Development, to Build-To-Print Production, through Integration and Testing. Every aspect of this model is guided by MTEQ’s Systems Engineering, Configuration Management, and Quality Assurance systems and processes. MTEQ’s scalable model can be applied to long-term or quick reaction efforts; we are experienced in streamlining our processes without sacrificing quality. 3.2 - Engineering, System Engineering and Process Engineering Support 3.4 - Prototyping, Pre-Production, Model-Making, and Fabrication Support 3.5 - System Design Documentation and Technical Data Support 3.11 - Quality Assurance (QA) Support A3 Payload Assembly Contract #: N00164-11-P-1040 Government POC: Rick Dorsey (Tel: 812-854-1675) MTEQ produced nine A3 Payload enclosures for NSWC Crane GBOSS Cerberus Lite LRU Production Contract #: N00164-10-C-JT02 Government POC: Brian Gage (Tel: 812-854-5287) MTEQ built 55 Sensor Interface Modules (SIM), 55 Portable Command Posts (PCP), 55 SIM to QPT Interface Cables, and SIM to PCP Interface Cables. GBOSS/Cerberus Lite Contract #: N00164-10-C-JT09 Government POC: James Lynch (Tel: 812-854-4298) MTEQ delivered 34 GBOSS Cerberus Lite Systems and 6 training systems.