Ibrahim et al - Scholarly Journals

advertisement

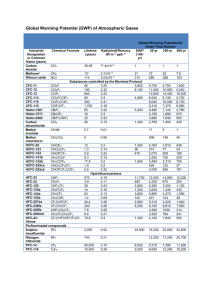

Scholarly Journal of Engineering Research Vol. x(x), pp. xxx-xxx September, 2013 Available online at http:// www.scholarly-journals.com/SJER ISSN 2276-8955 © 2013 Scholarly-Journals Full Length Research Paper Comparing the Yields of Biodiesel of Palm Oil and Jatropha curcas Seed Oil Using Bulk CaO Catalyst 1Ibrahim H*., 1Chika E., 1Hayatudeen A., 1Nwakuba C.D.U. 1Olabimtan O. 2Aminu A. 3Ibrahim M.A. 1Petrochemical Division, National Research Institute for Chemical Technology, Zaria, Nigeria. Engineering Department. Ahmadu Bello University, Zaria, Nigeria. 3Turkish-Nigerian University, Abuja, Nigeria. 2Chemical Accepted 11 September, 2013 Biodiesel is a renewable, biodegradable and environmental benign liquid fuel capable of replacing fossil diesel. In search of raw materials and methods for production of biodiesel at relatively low cost for it to be affordable, palm oil and Jatrpha curcas oil were transesterified with bulk Calcium oxide catalyst at the same reaction conditions of temperature, time, mole ratio and catalyst loading. At 600C and 90 minutes of reaction time, the yields of 86.41% and 99.08% for palm oil and Jatropha curcas oil were obtained respectively. The results obtained at 650C and 75 minutes were 89.41% and 96.93% for palm oil and Jatropha carcass oil respectively. For all the reactions the mole ratio of methanol to oil was 5.5:1 and the quantity of catalyst used was 1.5% w/w of oil. Therefore, Jatropha oil though not edible showed to have higher yield under the same reaction condition. The use of Jatropha oil and calcium oxide catalyst will make better alternative materials for biodiesel production in Nigeria as calcium carbonate is chiefly abundant in the Nigeria. Key words: palm oil, jatropha oil, calcium oxide, catalyst, biodiesel, production cost INTRODUCTION Biodiesel is a renewable, biodegradable and environmental benign liquid fuel capable of replacing fossil diesel. Biodiesel has a lot of advantages over fossil diesel such as; lubricating, low sulphur emission (Gerald et al, 2003), low greenhouse gas emission (Rubi et al, 2011), absence of aromatic compounds and its renewability. However, the cost of production of biodiesel is expensive, hence the diesel users do not ask for it which makes the business of producing it in Nigeria especially unattractive. As a prospective fuel it has to compete economically with petro-diesel therefore, the only way of reducing the biodiesel cost is to use less expensive process and raw materials such as nonedible oil and cheap catalysts. In this work, bulk calcium oxide catalyst was synthesized locally and it was used to produce biodiesel with Palm Oil (PO) and Jatropha curcas Oil (JCO) at the same reaction conditions of time and temperature and their yields were compared. Palm oil is in abundant in Nigeria but the used of it for biodiesel production will definitively affect its price and will result in food crisis. Jatropha curcas Oil is not edible and plant can be grown in non-arable land for biodiesel production without causing any food crisis. Calcium carbonate is also found in abundance in Nigeria hence; calcium oxide catalyst can easily and cheaply be synthesized for biodiesel production. This work was carried out in order to arouse interest of entrepreneurs into business of biodiesel production in Nigeria which will provide jobs and empower rural dwellers especially those living in non-arable land areas by farming Jatropha curcas seed for biodiesel production MATERIALS AND METHODS The materials used in this investigation include; an oven for drying the sample, a furnace for firing the catalyst and ceramic crucibles. A top loading balance, conical flasks, magnetic stirrer, hot plate, thermometer and separating funnel for separating biodiesel from glycerol were among *Corresponding author. E-mail: ibrahimhauna@yahoo.com. 1 temperature was maintained at 600C throughout the reaction period. In the second reaction same quantity of palm oil, methanol and catalyst were used at 650C for 75 minutes. The same procedure was repeated for J. curcas oil. The reactions were carried out in a conical flask covered with aluminium foil and was mounted on a magnetic stirrer. the apparatus used in this research work. The reagents used include, analytical grade methanol for transesterification, propan-2-ol, 0.1M potassium hydroxide for determination of FFA of the oils and GC-MS for biodiesel yield analysis. Preparation of Calcium oxide Catalyst Separation A bag weight of 50kg hydrated lime was collected from Pilot plant division of National Research Institute for Chemical Technology, Zaria. 200 g of the hydrated lime was dried in an oven to constant weight. The calcium oxide obtained was calcined in a furnace at 9000C for 90 minutes at 50% power rate. At the end of each reaction time the products were filtered and the filtrated were transferred into separating funnel and left for an hour or more to allow separation of biodiesel and glycerol. The residue was the solid catalyst (CaO). Glycerol which is denser than biodiesel was collected out at bottom of the funnel leaving biodiesel on top. These products were collected separately for analysis. Ca OH 2 CaO H 2O Determination of FFA and Esterification Ester Test The acid values of the two oil was first determine by dissolving I.0 g of oil sample in 25 ml of propan-2-ol and the solution formed was titrated against 0.1 M potassium hydroxide to pink colour. A blank titration was also performed by titrating 25 ml of propan-2-ol against 0.1 M potassium hydroxide to pink. The difference of the two titre values, v was used for determining the FFA. A quick test which is also called ester test was performed on each of the biodiesel sample produced by dissolving 10 ml of biodiesel in 40 ml of methanol. GC-MS Analysis Biodiesel sample from each batch was taken to GC-MS analysis in the instrumentation Division of National Research Institute for Chemical Technology, Zaria. 0.1M v 56.1g / mol FFA 1.0 g Where, v is the titre value. RESULTS AND DISCUSSION %FFA FFA / 2 Biodiesel is a mixture of alkyl alkanoates (alkyl esters) where the alkyl could be methyl, ethyl or any other higher alkyl radical depending from the alcohol that was used for the transesterification. When methanol is used the biodiesel will consists of methyl esters mixture and ethyl esters if ethanol is used. The methyl esters found in the biodiesel products are shown in the table below with their percentage composition. The results show that higher esters of 20 to 25 carbons though at relatively small amount were produced at higher temperature with palm oil and not much of such components were found in Jatropha curcas oil biodiesel products. Shown in the table are the names of the methyl esters, their molecular formulas (MF) and percentage compositions. These results show that the yield of biodiesel from palm oil increases with temperature as shown in the table from 60 to 650C but that of jatropha decreases, but at the same temperature Jatropha curcas oil yielded more biodiesel than palm oil. In the case of palm oil, 600C temperature favours meddle methyl esters of C17-C19 while 650C produced all ranges from C10 to C25 methyl esters. The The %FFA of palm oil was found to be 0.98% and that of the jatropha was 5.2%. The FFA of the jatropha was reduced to 0.87% by esterifying with methanol and concentrated sulphuric acid. This was done by heating 2.25 x 0.052 x 300 g of methanol and 0.05 x 0.052 x 300 g of sulphuric acid (Garpen et al, 2004) at 600C for 60 minutes on a magnetic stirrer. . (300 g was the mass oil that was esterified). Transesterification 300 g of palm oil was transesterified with 60 g methanol and 4.5g (1.5% mass of the oil) of the synthesized calcium oxide catalyst at 600C for 90 minutes. The palm oil was first heated to 600C in a conical flask and then, the calcium oxide and methanol mixture was poured into the hot oil. A magnetic stirrer was dropped into the reaction mixture to stir the reactants. The reaction 2 Table1: percentage composition of methyl esters in the products Methyl ester composition Methyl octanoate Methyl nonanoate Methyl decanoate Methyl 10-undecenoate Methyl undecanoate Methyl dodecanoate (laurate) Methyl tridecanoate Methyl mysristate Methyl pentadecanoate Methyl hexadecanoate Methyl palmitoleate Methyl -11-hexadecenoate Methyl-7-hexadecanoate Methyl 14-methylpentadecanoate Methyl 8-(2hexylcyclopropyl)ocatanoate Methyl 15-methylhexadecanoate Methyl linoate Methyl-9,12-octadecadienoate Methyl-8,11-octadecadienoate Methyl-10,13-octadecadienoate Methyl -3-octadecenoate Methyl oleate Methyl heptadecanoate Methyl cis-octadec-10-enoate Methyl cis-octadec-11-enoate Methyl trans-9-octadecanoate (elaide) Methyl -9-octadecenoate Methyl 9-octadecenoate Methyl -10-octadecenoate Methyl 7-octadecenoate Methyl 8-octadecenoate Methyl 15-octadecenoate Methyl octadecanoate Methyl 16-methylheptadecanoate Methyl hydrosterculate Methyl-10-nonadecenoate Methyl -11-icosenoate Methyl eicosanoate Methyl heneicosanoate Methyl -15-tetracosenoate Total MF PO % C9H18O2 C10H20O2 C11H22O2 C12H22O2 C12H24O2 C13H24O2 C14H28O2 C15H30O2 C16H32O2 C17H34O2 C17H32O2 C17H32O2 C17H32O2 C17H34O2 C18H34O2 C18H36O2 C19H34O2 C19H34O2 C19H34O2 C19H34O2 C19H36O2 C19H36O2 C18H36O2 C19H36O2 C19H36O2 C19H36O2 C19H36O2 C19H36O2 C19H36O2 C19H36O2 C19H36O2 C19H36O2 C19H38O2 C19H38O2 C20H38O2 C20H38O2 C21H40O2 C21H42O2 C22H44O2 C25H48O2 JCO % 0.054 0.054 JCO % 0.160 0.040 0.188 0.168 0.504 15.200 15.200 0.054 3.694 0.964 1.640 0.410 11.004 0.972 0.972 7.336 0.588 8.740 0.112 9.968 4.984 4.984 4.984 8.542 0.102 0.114 0.362 0.054 0.162 11.032 1.800 0.900 19.920 0.844 2.758 5.034 0.422 1.874 12.016 8.542 8.542 4.040 4.040 4.040 4.040 0.900 0.412 25.880 12.940 24.032 1.874 12.016 25.880 0.422 12.016 8.542 4.040 8.542 3.888 86.410 results of Jartopha curcas oil do not show much difference, however, methyl esters of C9 and C10 were found in 650C product but not in 600C product. The results also show that using Jatropha curcas seed Oil biodiesel can be produced at low temperature of 60 0C and using molar ratio of 5.5: 1 of methanol to oil. Temperature higher that 600C may results in lower yield. PO % 10.416 2.604 0.486 0.102 0.336 0.354 1.172 89.134 11.392 2.848 0.900 5.622 0.422 0.412 99.078 96.93 biodiesel production and it is very simple to synthesize. With calcium oxide, transesterification can now be carried out in 60 minutes as against 150 minutes (Isahak et al, 2010) and 180 minutes (Hawash et al, 2011). Also, with mole ratio 5.5:1 good yield can be obtained using calcium oxide catalyst as against 18:1 (Highina et al, 2011) and 12:1 (Hawash et al, 2011). The composition of biodiesel varies with reaction conditions. J. curcas seed oil can be relied upon among other non-edible seed oils for biodiesel production. The use of Jatropha curcas oil and calcium oxide catalyst will make better alternative materials of biodiesel production as calcium carbonate is CONCLUSION Calcium oxide catalyst is an excellent catalyst for 3 chiefly abundant in the Nigeria. ACKNOWLEDGEMENT All the reagents and materials used in carryout this belong National Research Institute for Chemical Technology NARICT, Zaria. REFERENCES Gerpen, J.V., Shanks, B., Pruszko, R., Clements, D. and Knothe, G. (2004). Biodiesel Production Technolog, National Renewable Energy Laboratory (NREL), 1617 Cole Boulevard, Golden, Colorado. Hawash, G.E.l., Diwani, E. and Abdel K. (2011). Optimization of Biodiesel Production from Jatropha Oil By Heterogeneous Base Catalysed Transesterification, Int. J. Engine. Sci. Technol. Highina, B.K., Bugaje I.M. and Umar B. (2011). Biodiesel production from Jatropha caucus oil in a batch reactor using zinc oxide as catalyst Journal of Petroleum Technology and Alternative Fuels Vol. 2(9), http://www.academicjournals.org/JPTAF Isahsk, W.N.R., Ismail, M.J., Jahim, M., Salimon, J. and Yarmo, M.A. (2010). Transesterification of Palm Oil Using Nano-Calcium oxide as a Solid Base Catalyst, World Appl. Science J. 9 (Special Issue of Nano Technology): 17-22, 2010 ISSN 1818-4952 4