5S Evaluation Checklist

advertisement

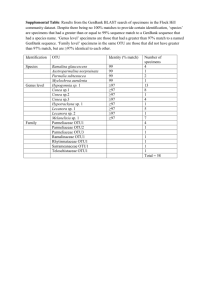

5S Evaluation Checklist Date: _________________ Location: ______________ Evaluator: _____________ Category Sort “Removing from the area items that are not needed for production or clerical operation.” Check Item Materials, Specimens Evaluation Criteria Excessive reagents; unnecessary kits; defective kits retained in area; extra parts; specimens piling up Equipment Unused instruments in the lab? Transport equipment stored in work cell? Tools Supplies Extra gloves, tape, pipet tips, test tubes, etc stored in work area? Withdrawal kanbans in place and being utilized? Extra/duplicate forms, office supplies clutter area; absence/obsolete standard work sheets; obsolete procedure manuals Containers Parts and reagent containers labeled? Cabinets, files, shelves, etc. labeled? Aisles, Floors New Specimens, SIP, Completed Specimens Storage locations marked? Safety equipment accessible and identified? Outsider can understand workflow and process visually? Items can be located immediately? Designated and clearly marked? Clear of obstructions? Properly stored? Quality standards visible and clear? Designated location for each item visually defined? Designated locations for untested, tested, and completed specimens? Equipment Clearly marked and accessible? Easy to locate/replace for anyone? Supplies maintained and controlled? Min/max levels marked and visible? Designated posting areas? Visible to operators? Visible to anyone auditing the work cell? Continual evaluation of methods and process to implement improvements? Equipment clean and orderly? Cleaning performed regularly and recorded? Specimens Specimens put away in timely fashion? Spills properly addressed? Supplies Supplies maintained and properly labeled? Supplies kept separate from specimens? Work areas Counter tops clean and orderly? Spill kits available? Disinfectant bottles filled? Paper towels available? Tools All tools clean and properly stored? Tools cleaned on a regular basis? Cleaning recorded? Documents Documents are clean and serum-free? Cleaning records are well maintained? Equipment, tools, supplies Documents, standards, charts, instructions Shine “Clean work areas improve employee morale and keep unneeded materials out of the workcell.” Unnecessary tables, cabinets, files, shelves etc. present? Unnecessary tools? Everything in its place? Documents Locations Stabilize “Arranging needed items so that they are easy to use and labeling them so that they are easy to find and put away.” Good: 3 Needs Improvement: 2 Not Good: 1 © 2004 Twenty-First Century Laboratory Consulting, LLC | M. S. Stegall & Associates, LLC Evaluation 5S Evaluation Checklist (continued) Date: _________________ Location: ______________ Evaluator: _____________ Category Check Item Materials Standardize “Everybody performs all operations the same way every time.” Equipment Tools Supplies Documents Workspace Sustain “All workers in the cell understand where things go, what to do, and when to do it.” Laboratorians Specimen Handling Documents, standards, charts, instructions Good: 3 Needs Improvement: 2 Not Good: 1 Evaluation Criteria Materials are stored and handled according to standard procedures? Equipment is maintained and operated according to standard procedures? The right tool is used at the right time? Tools are properly stored? Supplies used properly and as intended? Documentation of standard procedures is visible in the work cell. Results are promptly reported. New methods are continually proposed and tested. Clean and unobstructed? Everything in its place? All personnel have read and understand standard work? Personnel are actively pursuing process improvements? All specimens are handled in a safe manner? Specimens are properly and promptly stored when complete? Operators understand and utilize the documents posted in the work cell. Scheduled maintenance is performed and documented. Work improvement processes have been implemented. Results are promptly reported. © 2004 Twenty-First Century Laboratory Consulting, LLC | M. S. Stegall & Associates, LLC Evaluation