Seafloor Compliance Apparatus Guide

advertisement

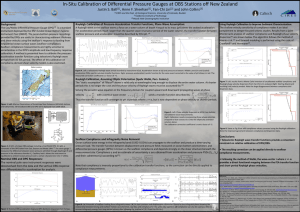

Seafloor Compliance Apparatus Guide Dr. Eleanor Willoughby April 17, 2012 The seafloor compliance (SFC) is the transfer function between pressure and displacement at the seafloor. The source of the pressure changes are wind- and coastline-excited ocean surface gravity waves, which, though evanescent, propagate down to the seafloor and measurably palpitate the ocean bottom. The ratio (more precisely, transfer function) between the pressure and the deformation is extremely sensitive to the shear modulus of the underlying material. This in turn, can be related to the materials which make up the seafloor and their time evolution. Hence, SFC data have been used to characterize gas hydrate deposits, which stiffen sediments when they displace seawater, and to monitor partial melt at mid-ocean ridges, which present an anomalously low shear modulus. This guide summarizes the hardware, software, use and maintenance of the NEPTUNE Canada SFC apparatus. The Apparatus To measure minute changes in pressure a Scripps Institute of Oceanography (SIO) Cox-Webb differential Pressure Gauge (DPG) can be used. Measuring minute displacements of the seafloor poses a serious technical problem as displacements can be as small as microns! The solution is to measure analogues of displacement. For instance, typical precision gravimeters have resolutions of 0.1 μgal or 10-9 m/s2 which are appropriate for compliance measurements. The NC SFC apparatus contains a custom Micro gLacoste gPhone gravimeter. To produce seafloor compliance spectra, time series data of pressure and acceleration must be gathered at 1 second sampling rates. 1. Gravimeter The gPhone gravimeter has ± 50 μgal dynamic range. It is based on a zero-length spring suspension system; acceleration data are the voltages applied to return the beam to its null position. It provides precise digital measurements of acceleration with 0.1 μgal resolution. The provided gMonitor software allows for the recording of location, time, date, raw gravity, sensor temperature, outer oven temperature, cross and long level values, and level corrections. The instrument itself has been customized for this deployment. Rather than recording atmospheric pressure (a redundant feature for an ocean-bottom deployment!) it has been interfaced to the DPG so that its ADC records the pressure data. The gMonitor program also handles two-way communication with the gravimeter, including the clamping and unclamping of the sensor. NOTE: during any transportation the sensor must be CLAMPED. Prior to recording meaningful data in situ it is necessary to communicate with the gPhone via gMonitor to set the sensor to UNCLAMPED. gPhone Specifications System Performance Resolution: 0.1 μGal Precision: 1 μGal System Noise: 6 μGal/√Hz or better Drift: 1.5 milliGal (or better) per month when new. With aging, drift values are usually less than 500 μGal/month Range: 7,000 milliGal uncalibrated (worldwide) Feedback range (during measurement): ±100 milliGals System Performance Size: 33 x 27 x 46 cm Mass of sensor: 14 kg Power: 24 V Further details on the gPhone can be found in the gPhone Brochure and gPhone/P.E.T. Hardware Manual (both available on the NEPTUNE Canada wiki). Note however that ‘TideDaq’ software has been replaced with gMonitor, the instrument has been customized (so there is no atmospheric pressure data, but it does record the DPG data) and the power specifications and the Timing Module are not pertinent to this instrument. For information on software, see the gMonitor help files. NOTE: The instrument manufacturer’s warranty ran for 1 year from the date of purchase (2007) and has now expired. The manufacturers however have shown great enthusiasm for NEPTUNE Canada and have always been extremely helpful with any questions or difficulties. 2. Differential Pressure Gauge The DPG is a SIO DPG. It measures minute changes in pressure by comparing ambient ocean pressure introduced via a diaphragm on the bottom with the pressure in a reference chamber by means of resistor bridge (specifically a piezoresistive strain gauges implanted into a Wheatstone bridge configuration formed on a miniature silicon diaphragm, a Lucas NovaSensor NPH Solid State Pressure Sensor). The sensor requires a constant current excitation to produce a voltage output. A ±7.2 V power input is rectified to 5V (on the analogue circuit board, following the SIO circuit design for the DPG power board) and fed to the DPG across two pins on its bulkhead connector (Impulse VSG-4-FS); the sensed voltage returns across the other two pins. The signal is input to a special analogue input on the custom designed gPhone. Figure 1 Typical analog board for a SIO DPG. The U of T version is based on the one designed by SIO, like the one above found on the NEPTUNE wiki. Further information can be found in the General Differential Pressure Gauge (DPG) Documentation (available on the NEPTUNE Canada wiki) and in Cox, C.,T., Deaton and S.C. Webb, ‘A Deep-Sea Differential Pressure Gauge’, Journal of Atmospheric and Oceanic Technology, (1984), volume 1, pp. 237-246. The DPG calibration is 0.186 ± 0.008 mV/Pa (see E.C. Willoughby, ‘Resource Evaluation of Marine Gas Hydrate Deposits Using the Seafloor Compliance Method: Experimental Methods and Results, Ph.D. thesis, (2003), University of Toronto). Note: The DPG has been replaced since the initial SFC deployment at Bullseye Vent. The original DPG did not perform to spec. The manufacturer’s warranty only covered its initial shipment to the University of Toronto and there is no further warranty. 3. Power supply: 48 V to 24 V converter The 48VDC power supply from the NEPTUNE Canada port is connected to the instrument and wired directly to a 48V to 24V converter, mounted within the pressure sphere, on the bottom of the gravimeter gimbals. Thus, the power supply does double-duty as ballast, ensuring the gravimeter gimbals will swing like a pendulum, and reach equilibrium with the gravimeter upright, very close to perfectly level. The power supply is a VHK-100W-Q48-S24. It features regulated output with continuous short circuit protection and means that the entire SFC apparatus is electrically isolated from the NEPTUNE Canada power supply. It is 87% efficient and contains its own heat sink. It has its own over-temperature shutdown feature. A full data sheet can be found at: http://products.cui.com/Product/Resource/3318/VHK100W.pdf A schematic diagram for the wiring is below. Figure 2 Schematic wiring diagram for SFC. Note the device is completely electrically isolated from NEPTUNE. 4. Power supply: 18 to 36 VDC to ± 7.2 VDC converter To power the analog DPG circuit board, ±7V are required. A custom-designed 24V to ±7.2 V converter was produced by TRUMPower. It is fully isolated, with continuous short circuit protection. A datasheet was provided to NEPTUNE. 5. Communications: Moxa NPort 5210 RS-232 to Ethernet converter The output from the DPG is interfaced to the modified gPhone and logged on its internal analog-todigital (Delta-Sigma type) converter. Thus, the gPhone handles all data and two-way communication. It outputs its datastream in RS-232, which is converted to Ethernet by an NPort 5210 (see http://www.moxa.com/product/nport_5210.htm ). This device is similar to those employed by NEPTUNE for communication in all ports. The NPort 5210 requires 24V to operate. 6. Gimbals The gPhone needs to be upright to record vertical accelerations of the seafloor. Ideally, it would be placed within remotely-controlled, self-levelling gimbals. However, these can be extremely expensive. We have employed our custom gimbals and allowed them to be freely moving, instead, as a means of remaining within budget. The gravimeter in its gimbals moves like a pendulum until it settles at its equilibrium, very nearly perfectly levelled. Laborious, precision fine-tuning of weights on the gimbals and levelling screws are needed so that gimbals natural fall to this near perfect position. It is important that the position selected for instrument deployment be a flat a possible (on a scale comparable to deployment package, roughly 2 m in diameter). When communicating with the gPhone, via gMonitor software, one can monitor the Long and Cross measurements. These record the divergence of the sensor from being perfectly plum, in two orthogonal directions. They are in arbitrary units. If the data are of the order of 30,000, then the readings are off-scale and cannot be trusted. Ideally, both Long and Cross would read 0 units (though this sort of perfection is virtually impossible). Readings of less than 6,000 units are best for good quality data. 7. Pressure vessel and deployment package The 60 cm diameter pressure sphere is rated for full ocean depths, and can be used down to 6 km. It is made of anodized aluminum. It has two half-spheres, and a mid-ring (complete with o-ring groves and orings, and three ports to the exterior). The ports allow for 1) connection to NEPTUNE via MINK connector with Delrin isolator; 2) connection to DPG and 3) connection to Prevco Pressure Release Valve via Delrin isolator. The sphere is bolted shut with bolts on the threaded rods on the triangular, Delrin bottom assembly box, and the thread rod on the tripod (each or which are supplied with a sacrificial anode). There are lead weights below the triangular box to ensure the device lands upright if dropped free-fall (not recommended – but the deployment package should be rugged enough to protect the instrument should this happen). The DPG is mounted in one of three corner, grey, cylinders, on the triangular bottom assembly box. Bolted to the side of the bottom assembly box is a holder for the under-water-mateable connection. Prior to deployment: the stainless steel screws on the MINK connector, holding it onto the isolator, should be replaced with titanium screws, to ensure no dissimilar metals are in direct contact. The MINK to under-water-mateable whip must also be added. 8. Pressure release valve A standard 01104-001 Titanium Pressure Relief Valve from PREVCO Subsea LLC (see http://www.prevco.com/Products/PressureRV.htm) was included on an otherwise unused mid-ring port, as per NEPTUNE’s instructions. Since the sphere is anodized aluminum, a special Delrin isolator was designed to prevent it from touching the sphere directly, to avoid corrosion. 9. Marine cables and bulkhead connectors The power to and data from the DPG comes from the pressure sphere via Teledyne Impulse 4-pin VSG marine cable and bulkhead connector (datasheet: http://www.teledyneimpulse.com/pdfs/1050/25InvGlassReinfEpoxyRubMolded/25.VSG_VMG.pdf) 10. Delrin isolators Two custom designed Delrin isolators were engineered and manufactured in-house at the Department of Physics of the University of Toronto. These allow the titanium Pressure Release Valve and MINK connector to be safely mated to the anodized aluminum pressure sphere. The concept is similar to isolators employed on the CSEM deployment. An o-ring seal (both barrel and face seals) is made between the isolator and the mid-ring, and a second seal is made between the device to be connected and the isolator. 11. Bottom assembly The entire apparatus is housed in a large Delrin, triangular box. The steel frame is protected with sacrificial anodes. The bottom is weighted with lead to ensure it lands upright. The assembly is rugged and has been used to deploy similar equipment with great success for two decades. Figure 3 The photo (by NEPTUNE Canada) shows the bottom assembly deployed at the Bullseye Vent JB, in its white Delrin triangular box, with the under-water-mateable connection in front.