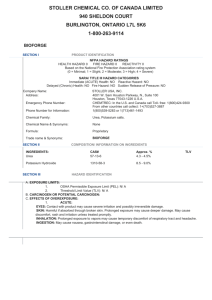

MSDS 1 - Fiberlay

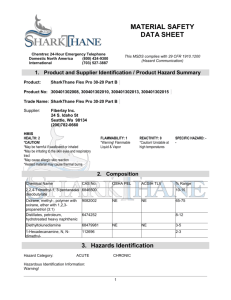

advertisement

MATERIAL SAFETY DATA SHEET Chemtrec 24-Hour Emergency Telephone Domestic North America (800) 424-9300 International (703) 527-3887 This MSDS complies with 29 CFR 1910.1200 (Hazard Communication) 1. Product and Supplier Identification / Product Hazard Summary Product: SharkThane Flex Pro 30-20 Part A Product No: 300401302008, 300401302010, 300401302013, 300401302015 Trade Name: SharkThane Flex Pro 30-20 Part A Supplier: Fiberlay Inc. 24 S. Idaho St Seattle, Wa 98134 (206)782-0660 HMIS HEALTH: 3 *CAUTION! *May be harmful if swallowed or inhaled *May be irritating to the skin eyes and respiratory tract *May cause allergic skin reaction *Heated material may cause thermal burns FLAMMABILITY: 1 *Warning! Flammable Liquid & Vapor REACTIVITY: 1 *Caution! Unstable at high temperatures SPECIFIC HAZARD: - 2. Composition Chemical Name CAS No. NTP Light Paraffinic Petroleum Oil Solvent Extract 2,2,4-Trimethyl-1, 3pentanediol diisobutyrate Toluenediisocyanate (mixed isomers) Poly(oxy(methyl-2ethane)), toluene diisocyanate polymer 64742058 % Range 5-10 6846500 30-40 26471625 IARC SARA 313 X X OSHA PEL 0.02 ppm 9057914 0.005 ppm Other Limits NE <1 60-70 3. Hazards Identification Hazard Category: ACGIH TLV ACUTE CHRONIC Hazardous Identification Information: Warning! 1 Dark liquid with a characteristic odor. Contains Toluene Diisocyanate (TDI) Inhalation of vapors may cause respiratory tract irritation. Contact with skin and eyes may cause irritation. 4. First Aid Measures Acute (Short-Term) Contact may cause slight irritation of the skin and eyes (tearing). Inhalation of vapors may cause irritation of the mucous membranes in the respiratory tract, running nose and sore throat. Chronic (Delayed) Repeated or prolonged inhalation of TDI vapors above the TLV of 0.02 ppm can cause immediate or delayed respiratory sensitization and asthma-like conditions. Repeated skin and eye contact may cause reddening, swelling, or skin sensitization in susceptible individuals. Inhalation: Remove source(s) of contamination and move victim to fresh air. If breathing has stopped, give artificial respiration, then oxygen if needed. Contact physician immediately. Eye Contact: Flush eyes with water for at least 15 minutes. If irritation persists, seek medical attention. Skin Contact: Remove contaminated clothing and wash affected area with isopropyl alcohol, followed by soap and water. Ingestion: Do NOT induce vomiting. Contact a physician. Do NOT give anything by mouth to an unconscious person. After first aid, get appropriate in-plant, paramedic, or community medical support. 5. Fire Fighting Measures Flash Point: >300°F Flash Point Method: PMCC LEL: Not Established UEL: Not Established Flammability Classification: Non-Flammable Extinguishing Media: Water Fog, Dry Chemical, and Carbon Dioxide Foam Unusual Fire or Explosion Hazards: Hazardous decomposition products may be formed. Avoid water contamination in closed containers or confined areas as exothermic heat and carbon dioxide can evolve. Fire-Fighting Instructions: Fire fighters should wear self-contained breathing apparatus. Do not release runoff from fire control methods to sewers or waterways. Fire-Fighting Equipment: Because fire may produce toxic thermal decomposition products, wear a selfcontained breathing apparatus (SCBA) with a full face piece operated in pressure demand or positivepressure mode. 6. Accidental Release Measures Wear protective equipment. Ventilate spill area. Cover liquid with an absorbent material (sawdust, vermiculite or wet sand). After the material is absorbed scoop up and place in open containers. Treat material with the prepared decontamination solution and leave the container open in a well-ventilated area for 48 hours. Spill area should also be decontaminated with the following decontamination solution: 90% water, 2% detergent and 8% concentrated ammonia or sodium carbonate. 2 7. Handling and Storage Handling Precautions: Minimize breathing of vapors and avoid prolonged or repeated contact with skin. Wear proper protective equipment. If ventilation is not sufficient, wear proper respiratory equipment. Avoid moisture contamination. Reseal partial containers. Use good general housekeeping procedures. Storage Requirements: Store in tightly closed containers in a cool, dry place. Protect from heat and moisture contamination. Do not reseal containers if contamination is suspected. 8. Exposure Controls, Personal Protection Respiratory Protection: Follow OSHA respirator regulations 29 CFR 1910.134 and European Standard EN 149; wear an MSHA/NIOSH or European Standard EN149 approved respirator. Protective Clothing/Equipment: Wear chemically protective gloves to prevent prolonged or repeated skin contact. Wear protective eyeglasses or chemical safety goggles, per OSHA eye and face-protection regulations 29 CFR 1910.133 and European Standard EN166. Contact lenses are not eye protective devices. Appropriate eye protection must be worn instead of, or in conjunction with contact lenses. Comments: Never eat, drink, or smoke in work areas. Practice good personal hygiene after using this material, especially before eating, drinking, smoking, using the toilet, or applying cosmetics 9. Physical and Chemical Properties Physical State: Liquid Appearance: Dark Odor: Characteristic odor Vapor Pressure: NE Vapor Density (Air=1): ˃1 Specific Gravity (H2O=1, at 4 °C): 1.05 Water Solubility: Reacts slowly to liberate CO2 gas Boiling Point: None >400˚F % Volatile: Negligible Freezing/Melting Point: NA Viscosity: 600 CPS @ 75˚F(24˚C) Evaporation Rate: NA 10. Stability and Reactivity Stability: Stable Polymerization: May occur. Avoid incompatible reactants, especially strong bases, water or temperatures above 100˚F. Chemical Incompatibilities: Water, bases, amines, alcohols and oxidizing agents and other materials which react with isocyanates. Hazardous Decomposition Products: High temperatures and burning conditions may release TDI vapors, cyanates, hydrocarbons, oxides of carbon and nitrogen and traces of HCN. 11. Toxicological Information None Available 3 12. Ecological Information None Available 13. Disposal Considerations Waste must be disposed of in accordance with federal, state and local environmental regulations. Incinerate or bury in a licensed facility. 14. Transport Information Toluene Diisocyanate's RQ- 100lbs This product's RQ (with 1% TDI) consequently -10,000lbs In quantity in one package equals or exceeds RQ (CFR 49 171.8) Shipping Name: Toxic liquid, organic n.o.s Contains Toluene Diisocyanate (TDI) Hazard Class: 6.1 Packing Group: III UN 2810 Otherwise: Not regulated by DOT 15. Regulatory Information TSCA Inventory Status: This product, or its components, are listed on, or are exempt from the Toxic Substance Control Act (TSCA) Chemical Substance Inventory. Toluene Diisocyanate CAS# 26471-62-5 contains 2,4 Toluene Diisocyanate CAS# 584-84-9 and 2,6 Toluene Diisocyanate CAS# 91-08-7. SARA Toxic Chemical (40 CFR 372.65): These products contain the following chemicals that are subject to release reporting requirements under section 313 of SARA Title III of the Superfund Amendments and Reauthorization Act of 1986 and 40CFR part 372: Chemical Name 2,4 Toluene Diisocyanate 2,6 Toluene Diisocyanate CAS NUMBER 584-84-9 91-08-7 CONCENTRATION <2% <1% SARA HAZARD CATEGORY: This product has been reviewed according to the EPS "Hazard Categories" promulgated under Sections 311 and 312 of the Superfund Amendment and Reauthorization Act of 1986 (SARA Title III) and is considered, under and immediate health hazard; A delayed hazard 16. Other Information California Proposition 65 involving warnings of the presence of certain listed chemicals is now in effect. In order to comply with the California Law, even though some of the listed substances may not represent a significant risk as defined by the regulations, we feel obligated to make the following statement: “Warning: This product may contain trace amounts of some chemicals considered by the State of California to be carcinogens or reproductive Toxicants.” Preparation Date: 2/9/2016 4