Final Session 16 SEVESO Case study BowTie ( -> 117 kb )

advertisement

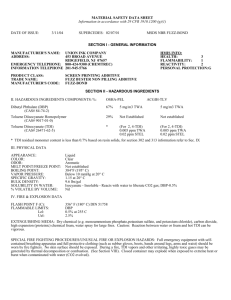

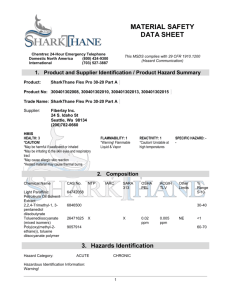

CASE STUDY :HAZARDS AND RISKS - BOWTIE Purpose: To learn how to use a risk assessment tool like BowTie. The bow-tie is a model that represents how a Hazard can be released, escalate, and how it is controlled. 1. Describe for the EFOAM case study the major hazard and top event? Under Hazard is meant a potential to cause harm, including ill health and injury, damage to property, products or the environment; production losses or increased liabilities. The Top Event is than the incident that occurs when a Hazard is realised, or the release of the Hazard. The Top Event is typically some type of loss of control or release of energy. If this event can be prevented there can be no effect or Consequence from the Hazard. 2. Which threats can lead to release of the Hazard and can thus cause the Top Event? 3. Which barriers prevent the probability of each Threat? 4. What are the consequence of the potential hazardous outcomes arising from the Top Event.? 5. Which barriers mitigate or limit the extent of, or provide immediate recovery from the Consequences? . HYPOTHETICAL CASE STUDY: EFOAM, A PLASTICS FACTORY EFOAM is a factory producing polyurethane foam. Its products include foam for insulation in buildings and for packaging. The factory is located on the edge of Atalanta, a city of 5 million inhabitants, and near a river which flows through the densely populated neighbourhood into the city. Most of the workers live within walking distance. Numerous other small factories are located in the same area. Both the factories and the city use the river for the disposal of untreated sewage and industrial liquid wastes. The main part of the city is situated in a valley surrounded by hills. The city has two well-respected universities and a number of private technical and business schools, but the average factory worker has not attended school for more than six years. Most of the workers at EFOAM have from five to eight years of schooling; most of the managers have completed 12 years of school; two of the managers have degrees in mechanical engineering. There is an on-site first aid facility, but no doctor. The factory has never carried out a formal risk assessment of its operations or developed an emergency response plan. As no files have been kept on applicable regulations, it is not known whether the factory has all the permits it needs or whether it is in compliance with its permits. It does pay annual fees to the City of Atalanta for the use of water, and waste water emissions to the river. The fees are calculated on the basis of estimates of water use and emissions. No monitoring has been done The factory uses toluene diisocyanate (TDI) as a starting material to produce both rigid and flexible foams for a variety of customers. At any time there are around 150 tonnes of TDI, 200 tonnes of polyol, 2 tonnes of amines, and 1 tonne of silicone agent on the site. Up to 300 tonnes of finished foam may be stored on-site, waiting for shipment to clients. About 120 employees work at the factory and simple meals are provided by an on-site cafetaria. TDIs are synthetic organic chemicals with a molecular formula of C9H6N202. TDI-based polyurethane foams are widely used in the automotive and furniture industries, and in packaging and insulation Polyols, various amines (catalysts) and silicone copolymers are used in the production process, which is fairly simple. In most cases, the TDI and other chemicals are imported. A simplified reaction equation of the overall process is: TDI + Polyol + Catalyst + Blowing Agent + Stabiliser = Polyurethane foam The raw materials are injected under pressure with precision dosing pumps into a mixing chamber where they are intimately mixed. The resulting active mixture expands rapidly with the simultaneous generation of considerable heat. It is injected into different types of molds, depending on the client's needs. At the end of the reaction the foam solidifies and hardens. The blocks of foam are released from their molds, cut, wrapped and packaged, and stored for shipment. The packaging materials are plastic foil and cardboard. Shipping is by truck. TDI is a known animal carcinogen. However, it is not listed as a potential human carcinogen. Exposure to TDI can lead to adverse effects on the respiratory tract, skin, eyes, and gastrointestinal tract. See the Material Safety Data Sheet for more details. The polyols are stable at high temperature and relatively inoffensive. Triethylamine is an irritant which is corrosive to the skin. Under prolonged exposure it may affect the cornea. TDI may react violently with water or alcohols, amines, bases, acids, and polymerisation activators. The reaction may liberate gases and cause the liquids to splash onto nearby objects or people. Many of these chemicals are highly persistent in the soil or water. There is some risk of auto-ignition of the freshly formed foam immediately after production. The caloric value of the foam is around 10,000 KcaL/kg, sufficient to allow rapid propagation of a fire. Burning foam releases noxious fumes containing a wide range of highly toxic compounds. The main toxic compound produced by burning plastic is carbon monoxide. Other toxic compounds which may be present include hydrogen cyanide and hydrogen chloride, which are likely to be emitted by any compound containing nitrogen and chlorine, respectively. Material Safety Data Sheet TOLUENE-2,4-DIISOCYANATE SECTION 1. MATERIAL IDENTIFICATION Description (Origin/Uses): Usually prepared from toluene-2,4-diamine and phosgene. Used widely in the rnanufacture of polyurethane foams, elastomers, and coatings, all of which have extensive comrnercial and industrial applications. Other Designations: TDI; 2,4-Diisocyanate-l-Methylbenzene; 2,4 Diisocyanatotoluene; 2,4- Tolylene Diisocyanate; C9H6N202, CAS No. 0584-84-9 SECTION 2. INGREDIENTS AND OCCUPATIONAL EXPOSURE LIMITS Toluene-2,4-Diisocyanate, ca 100%: OSHA PELS; ACGIH TLVS, 1988-89; NIOSH RELS, 1978; 8hr TWA: 0.005 pprn, 0,04 mg/m3 TLV-TWA: 0.005 ppm, 0,04 mg/m3@ 10-br TWA:0.005 ppm, 0,036 mg/m3; 15-rnin STEL: 0.02 ppm, 0,15rng/m3; TLV-STEL: 0.02 pprn, 0, 15 mg/m3; 20-min Ceiling: 0.02 ppm, 0, 14 mg/m3 Toxicity Data*: Human Inhalation, TCLo: 0,5 ppm *See NIOSH, RTECS (CZ6300000), for additional data on toxicity with references to irritative, tumorigenic, and mutagenic effects. SECTION 3. PHYSICAL DATA Boiling point: 482°F (250 °C)* % Volatile by Volume: ca 100; Melting Point: ca 54 °F (1 2% C)*; Molecular Weight: 174 g/mol; Vapor Density (Air= l): 6.0 Specific Gravity (H20=1): 1.22 at 77°F (25°C)*; Vapor Pressure: 0.025 Torr Solubility in Water (%): TDI reacts exothermically (produces heat) with water to form carbon dioxide (C02). Appearance and Odor: A clear, colorless liquid (darkens upon exposure to sunlight); a sharp, irritating, pungent odor. Comments: Toluene diisocyanate is commercially available as the two isomers 2,4-TDI and 2,6-TDI. Commercial mixtures of TDI are available in the following three ratios: (1) 100% (2) 80% 2,4; 20% 2,6; (3) 65% 2,4; 35% 2,6. The 80% 2,4; 20% 2,6 commercial mixture represents over 95% of current industrial usages. *Specific to the 80% 2,4; 20% 2,6 product. SECTION 4. FIRE AND EXPLOSION DATA Flash Point: 266°F (130°C); Autoignition Temperature: Not Found; LEL: 0.9% v/v UEL: 9.5% v/v Extinguishing Media: This highly combustible liquid can be dangerous during fires; it is often mixed with flammable, volatile solvents. Use carbon dioxide (C02) and water spray to extinguish toluene-2,4-diisocyanate fires. Unusual Fire or Explosion Hazards: Containers of TDI can rupture violently when heated; cool exposed containers or tanks of this material with water spray. Special Fire-fighting Procedures: Wear a self-contained breathing apparatus (SCBA) with a full facepiece operated in the pressure-demand or positive-pressure mode. SECTION 5. REACTIVITY DATA Stability/Polymerisation: Toluene-2,4-diisocyanate is stable in closed containers during routine operations at room temperature. Hazardous polymerisation can occur if it is exposed to concentrated alkaline compounds such as sodium hydroxide (NAOH) or to tert-amine compounds. Chemical Incompatibilities: Hazardous reactions can occur between TDI and certain compounds containing active hydrogen (such as water, ammonia, amines, alcohols, and caustics such as sodium hydroxide, etc.). The reaction with water produces heat and carbon dioxide. Conditions to avoid: Prevent exposure to incompatible chemicals, sources of ignition, and ultraviolet light (yellow discoloration is otherwise likely). Hazardous Products of Decomposition: During fires, thermal oxidative degradation of toluene-2,4-diisocyanate can produce toxic gases such as carbon monoxide (CO), carbon dioxide (C02), and oxides of nitrogen (N02). SECTION 6. HEALTH HAZARD INFORMATION Carcinogenicity: Toluene-2,4-diisocyanate is not listed as a carcinogen by the NTP, IARC, or OSHA. Summary of Risks: TDI exhibits low oral toxicity; however, inhalation of very small amounts of it causes severe irritation of the respiratory system. Skin contact with TDI causes redness, swelling, and blistering, leading to allergic eczema and skin sensitisation to future TDI exposure. Ingestion causes corrosive damage to the gastrointestinal tract. Medical Conditions Aggravated by Long-Term Exposure: Existing asthma, allergies, or respiratory problems. Primary Entry: Inhalation, skin contact. Acute Effects: Severe irritation of the mucous membranes, respiratory tract, and eyes; acute asthmatic attacks; a choking sensation, chest pain, waves of productive coughing (if breathing-zone concentration reaches 0.5 ppm, the possibility of respiratory response is imminent with latent periods of 4 to 8 hours; abdominal distress, nausea, and vomiting; and skin irritation. Chronic Effects: Allergic, asthmatic respiratory sensitivity to future TDI exposure is likely unless present exposure to it is strictly limited or controlled. The hypersensitivity of certain individuals to this material can result in long-term effects or sensitisation, even at low exposure of 0.02 pprn and below and rnay take 6 months to 20 years to develop. Skin sensitisation is another possibility. Once sensitised, reactions can occur to concentrations of 0.005 pprn or less. First Aid: Eyes. Immediately flush eyes, including under the eyelids, gently but thoroughly with flooding amounts of running water for at least 15 minutes. Skin. Rinse the affected area with a flooding amount of water; wash it with soap and water. Inhalation. Remove the exposed person to fresh air; restore and/or support his or her breathing as needed. Have qualified medical personnel administer oxygen as required. Keep him or her warm and at rest until medical help is available. Ingestion. Unlikely. Should accidental ingestion occur, give the exposed person 2 to 3 glasses of water to drink and induce vomiting. Get in-plant, paramedic, or community medical help for all exposures. Seek prompt medical assistance for further treatment, observation, and support after first aid. Note to Physician: If severe inhalation exposure is suspected, immediate hospitalisation with careful monitoring for the delayed (up to 72 hours) onset of pulmonary edema is suggested. Steroids may be useful in decreasing or controlling the inflammatory response of the lungs if administered on a shortterm basis (2 to 4 days) Detailed preplacement and annual medical exams with special attention to pulmonary function studies, heart, lungs, and allergic responses or symptoms are recommended for workers who may be exposed to TDI. SECTION 7. SPILL, LEAK, AND DISPOSAL PROCEDURES Spill/Leak: Notify safety personnel, evacuate unnecessary personnel, eliminate sources of ignition, and provide adequate ventilation in the event of a tolucnc-2,4-diisocyanate spill or leak. Cleanup personnel must wear protective respiratory equipment to prevent inhalation of TDI (see sect. 8); skin or eye contact must also be prevented. Absorb the spilled TDI with material such as vermiculite or sawdust and place it into appropriate containers suitable for eventual disposal or reclamation. Waste Disposal: Contact your supplier or a licensed contractor for detailed recommendations. Follow Federal, state, and local regulations. Neutralize TDI residue in drurns before they are disposed of or reused. Contact your supplier for neutralizing instructions. OSHA Designations: Listed as an Air Contaminant (29 CFR 19 1 0. 1 000 Subpart Z) EPA Designations: Listed as RCRA Hazardous Waste N' U223 (40 CFR 261.33) Listed as CERCLA Hazardous Substance* (40 CFR 302.4), Reportable Quantity (RQ): 100 Ib (45.4 kg), [*per RCRA, § 3001 l; Listed as a SARA Extremely Hazardous Substance (40 CFR 355), Threshold Planning Quantity (TPQ): 500 lb; Listed as a SARA Toxic Chemical* (40 CFR 372.65) (*EPA Form R may apply to your facility; see 40 CFR 372.85 for instructions) SECTION 8. SPECIAL PROTECTION INFORMATION Goggles: Always wear protective eyeglasses or chemical safety goggles. Wear a full face shield where splashing of toluene-2,4-diisocyanate or its solutions is possible. Follow OSHA eye- and faceprotection regulations (29 CFR 1910.133). Respirator: Wear a NIOSH-approved respirator per Genium reference 88 for the maximum- use concentrations an/or the exposure limits cited in section 2. Follow OSH respirator regulations (29 CFR 1910.134). For emergency or nonroutine operations (leaks or cleaning reactor vessels and storage tanks), wear an SCBA. Warning: Air-purifying respirators will not protect workers in oxygendeficient atmospheres. Other: Wear impervious butyl rubber gloves, boots, aprons, and gauntlets to prevent skin contact with TDI. Ventilation: Install and operate general and local maximum explosion-proof ventilation systems powerful enough to maintain airborne TDI concentrations below the OSHA PEL standard cited in section 2. Local exhaust ventilation is preferred because it prevents dispersion of the contaminant into the general work area by eliminating it at its source. Consult the latest edition of Geniurn reference 103 for detailed recommendations. Safety Stations: Make emergency eyewash stations, safety/quick-drench showers, and washing facilities available in work areas. Contaminated Equipment: Contact lenses pose a special hazard; soft lenses may absorb irritants and all lenses concentrate them. Do not wear contact lenses in any work area. Remove and launder contaminated clothing before wearing it again; clean this material from your shoes and equipment. Comments: Practice good personal hygiene; always wash thoroughly after using this material and before eating, drinking, smoking, using the toilet, or applying cosmetics. Keep it off your clothing and equipment. Avoid transferring it from your hands to your mouth while eating, drinking, or smoking. Do not eat, drink or smoke in work areas. Do not inhale TDI vapor. SECTION 9. SPECIAL PRECAUTIONS AND COMMENTS Storage/Segregation: Store toluene-2,4-diisocyanate in closed containers in a cool, dry, wellventilated area away from sources of heat or ignition, incompatible chemicals, and strong oxidizing materials. Shade the containers from direct sunlight. Outside, isolated, detached, or remote storage is recommended for bulk quantities. TDI that is stored in tanks should be blanketed with an inert gas such as nitrogen or dry air. Engineering Controls: Properly ventilate all work areas. Electrically ground and bond all containers used in shipping, receiving, transferring, or sampling operations to prevent static sparks. Other Precautions: Sensitized workers must be kept away from virtually all exposures to totuene-2,4dlisocyanate. Careful monitoring of the workplace level of TDI and the workers' responses to it is suggested. Transportation Date (49 CFR 172.101-2) DOT Shipping Name: Toluene Diisocyanate IMO Shipping name: Toluene Diisocyanate DOT Hazard Class: Poison B IMO Hazard Class: 6.1 DOT ID No: UN 2078 IMO Label: Poison DOT LABLE: Poison IMDG Packaging Group: 11 173.346 DOT Packaging Exceptions: 49 CFR 173.345 DOT Packaging Requirements: 49 CFR References: 1, 6, 26, 38, 74-94, 100, 116, 118, 119, 122