Lab infrastructure and Expertise The Food Microbiology and

advertisement

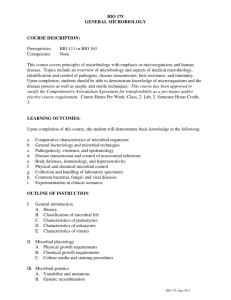

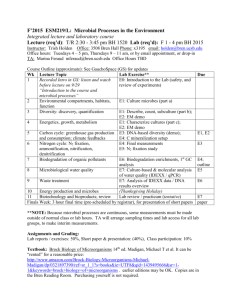

Lab infrastructure and Expertise The Food Microbiology and Biotechnology lab at the Department of Food Science is a well equipped and well organised lab with several research interests and relative expertise in the area of food biotechnology and applied microbiology, including microbial fermentations, applied microbial physiology, bioprocess monitoring and control, biosynthesis and process optimisation of microbial polysaccharides, organic acids, bacteriocins, single cell protein, bioethanol, etc, production of fermented food and beverage using immobilised microbial cells, etc, as well as food microbiology topics such as antimicrobial activity of natural ingredients (essential oils, organic acids, bacteriocins, etc) against food pathogens and spoilage organisms, production of low-processed foods or preservative-free foods via hurdle technology, estimation of microbial growth and improvement of food shelf-life, use of probiotics or bacteriocin-producing bacteria in dairy and meat products, etc. Current research involves: - The production of gellan gum by deproteinized cheese whey and dephenolised olive mill waste - The production of single cell protein by deproteinized cheese whey and dephenolized olive mill waste - The production of bioethanol by deproteinized cheese whey - The production of bacteriocins (curvasin, nisin) by lactic acid bacteria - The use of organic acids and bacteriocin-producing bacteria for the extension of shelf life of packaged meat (and improvement of sensory characteristics) - The in vitro and in vivo (after addition if foods) of the antimicrobial activity of several natural essential oils from aromatic plants - The production of nitrite-free fermented sausages using protective cultures - The preservation of sulfite-free peeled vacuum-packed potatoes using organic acids and (metal) sequestrants Future research which is expected to commence shortly also includes: - The production of antimicrobial and immunostimulating (e.g. antitumor) microbial polysaccharides - The production of natamycin and/or the direct use of S. natalensis as antimicrobial agent - The use of bacteriophages for food preservation - The monitoring and control of fungal growth and spoilage in foods via on-line direct microscopy - The production of beverages using immobilized yeast or bacterial cells for flavor enhancement and/or accelerated fermentation/ripening The infrastructure of the lab includes: - 2 15L STR fermentor sterilized in-situ and fully automated - 2 orbital incubating shakers (one with cooling capacity) - a gel permeation chromatography (GPC-SEC) system with RI detector - 3 (heating) incubators and 2 (heating/cooling) incubators - 12 optical microscopes and one with digital camera attached (for live imaging and image analysis) - a Brookfield viscometer - a laminal flow cabinet - a 75L autoclave - a single beam photometer (a UV-Vis double beam spectrophotometer is also available in the department) - a bench centrifuge (another large ultracentrifuge is expected soon) - a digital plate colony counter Also relative and available equipment in the department's labs include: - an ELISA system - a PCR system (Real Time PCR is ecpected soon) - Gel electrophoresis and gel imaging system - Fluorescent microscopy - HPLC, GC-MS systems - Differential scanning calorimetry - Spray-drying and lyophilisation systems ...and much more analytical and processing equipment