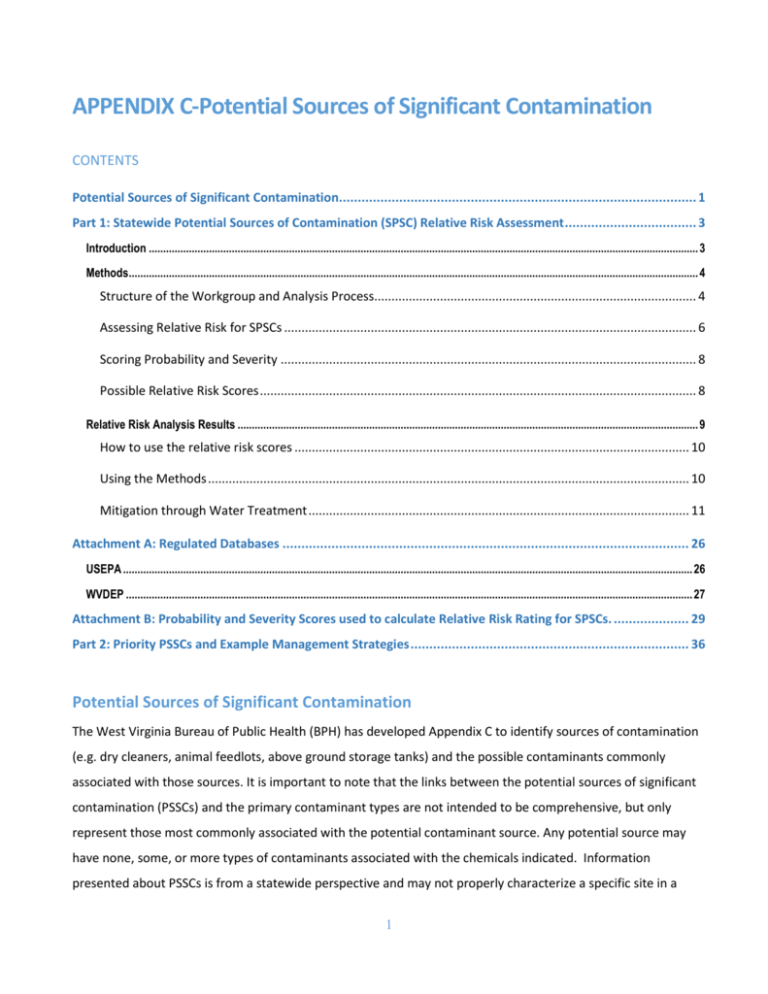

Potential Sources of Significant Contamination

advertisement