Our ref: CD/TM/Q17263

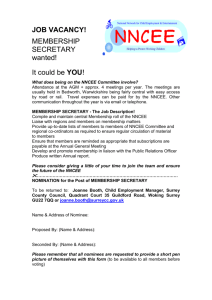

advertisement

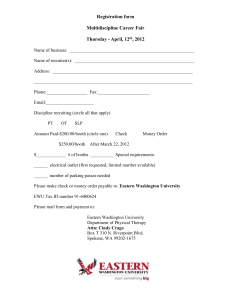

Union New Jersey Prepared by E. Ferguson EXTRACT TECHNOLOGY Client : Schering Plough Site: Union, NJ Q16399 (Rev4) Date: 10 Feb 2004 ETL Engineer: Eric Ferguson CLS Ref: Q16399 (Rev IV) 10 February, 2004 For the attention of Tracee Wright Schering Plough 1700 Galloping Hill Road Rondell Building -20 Kenilworth, NJ 07033 Telephone 908 298 5546 Dear Tracee, RE: Solvent Booth Package Drum Storage Building in Union, NJ Thank you for your continued interest in Carlisle Life Sciences. Extract is pleased to provide you with our revision 4 Proposal Q16399 for your review and consideration. Please refer to layout drawing Q16399-(GA2). This drawing illustrates the dimensions and arrangement of our Downflow booth, sliding doors, conveyors, turntable and raised internal flooring. We trust we have interpreted all your requirements correctly and we look forward to further discussions in the very near future. Should you have any questions or require additional information, please do not hesitate to contact us. Very truly yours, Joseph W. Schirmer, CSE CLS Main Office: 618 State Street, New Lisbon, WI 53950 Tel.: 800-356-5734 Fax: 608-562-5956 East Coast Office: 79 Veronica Avenue, Somerset, NJ 08873 Tel.: 732-873-4100 Fax: 732-873-4111 E-mail: Info@carlislelifesciences.com Internet: www.carlislelifesciences.com -1- Client : Schering Plough Site: Union, NJ Q16399 (Rev4) Date: 10 Feb 2004 ETL Engineer: Eric Ferguson EXTRACT TECHNOLOGY LIMITED DOWNFLOW SINGLE PASS SOLVENT BOOTH TECHNICAL SPECIFICATION Client: Schering Plough Site: Union, NJ ETL Ref No.: Q16399 (Rev4) Qty Description Building 1 2.5m wide DX 6/9/12B Single Pass Downflow Solvent Booth W/ Sliding Doors, Conveyors and Turntable Drum Storage Building Union, NJ Dust in Air Level:- Operator Exposure Level (OEL) 50 - 100 µg/m³ TWA over operation period. All OEL’s are dependent upon the operators following Carlisle Life Sciences operator training practises and safe working methods. Airflow Management:- Single pass airflow with Downflow velocity of 0.5m/s (98 fpm) +/- 10%, circa 750 ACH (Air Changes per Hour) Noise Levels:- Below 78dBA (free field subject to building / surrounding area) within the booth work area, 1.0m away from rear bulkhead. Lighting Levels:- Lighting levels 1.0m above floor level within the working area would be 250 Lux. A standard safety feature ensures that the lights do not operate without the fan running. Booth Air Temperature Control:- Due to the single pass system, no control systems are required to offset the temperature and humidity. -2- Client : Schering Plough Site: Union, NJ Q16399 (Rev4) Date: 10 Feb 2004 ETL Engineer: Eric Ferguson Typical airflow movement within downflow booth or workstation. Excellent containment levels achieved by combining downflow over operation with rear exhaust Guaranteed operator exposure levels (O.E.L). Flexibility to individual client needs. Potential dust sources suppressed by downflow air. Integrated mechanical handling devices. Proven solutions worldwide. Dispensing, Sampling, charging operations. Personnel/material airlock integration. Designed and manufactured to latest cGMP standards. Complimented with full DQ/IQ/OQ validation package. Fully integrated with surrounding environment. Temperature controlled work area. On board filtration package, including safe change. Low operating maintenance costs. -3- Client : Schering Plough Site: Union, NJ Q16399 (Rev4) Date: 10 Feb 2004 ETL Engineer: Eric Ferguson EQUIPMENT PROVIDED One 2.5m DX Single Pass Solvent Booth Special Features The following special features have been incorporated within the booth design to provide a purpose designed system:A “Closed loop” control system automatically increases fan speed to compensate for filter blockage. B Base plinth, 100mm (4") high in stainless steel below technical stack and sidewalls. 10mm (3/8") recess around internal faces to allow for coving. Coving supplied and fitted by client C Sprinkler penetration through ceiling plenum c/w sealed tube welded in place. All pipes and nozzles by client D Rear Bulkhead, Interior and Exterior walls in 304 grade Stainless Steel E Code 12B Filtration, which incorporates Fine Dust Filters in Safe Change Housings, midstage HEPA filters in Safe Change Housings and ceiling mounted HEPA Filters F Exhaust Fan and Motor G Supply air (4964 CFM) duct work to ceiling plenum excluded from Carlisle Life Sciences scope of supply H Internal ceiling height of 8’-6” to accommodate sliding doors I All internal electrics, RHS roller conveyor and booth motor to be Class I Div 2 rated J Two, (2) electrically automated St. St. sliding doors vision panel. Door on RHS – looking in- to be class 1 div 2 rated. Door on LHS- looking in, to not be electrically rated as motor will be outside of booth in safe area. K Extended and structurally reinforced side panels to accommodate weight and size of sliding doors L XP rated Audible and Visual Alarm panel for all gauges inside the booth Optional Features The following Optional features are priced out separately in the cost section:1 Electrically automated rollers to aid manoeuvre of pallets entering and exiting the booth. Electrically automated pallet turntable with automated rollers to rotate and position the pallets within the booths work area. Also includes raised flooring to elevate operator allowing ergonomic access to the drums on the pallet. -4- Client : Schering Plough Site: Union, NJ Q16399 (Rev4) Date: 10 Feb 2004 ETL Engineer: Eric Ferguson STANDARD SPECIFICATION DOWNFLOW BOOTH CONSTRUCTION : CODE 6S Item No. MATERIAL COMPONENT Zintec - Epoxy Powder Coated White 304 Stainless Steel - 240S Finish 1 Wall Panels Yes 2 Infill Skins Yes 3 Rear Bulkhead Yes 4 Downflow Workbench N/A 5 Spillage Trays Exhaust Plates (Magnetic Fixing) Exhaust Plates (Bolted Fixing) Exhaust Plenum N/A 6 6 7 8 9 10 11 Filter Housings Return Air Duct c/w Internal Acoustic Foam Overhead Supply Plenum/Panels Floor Plinth Yes N/A Yes Yes Yes Yes Yes -5- 316L Stainless Steel - 240S Finish Client : Schering Plough Site: Union, NJ Q16399 (Rev4) Date: 10 Feb 2004 ETL Engineer: Eric Ferguson STANDARD SPECIFICATION DRIVE AND ELECTRICAL CODE 9 : 460V 60Hz 3ph +E FAN TYPE Construction: Fan : Housing Duplex double inlet double width centrifugal directly driven Galvanised sheet steel with anti-spark copper end plates Epoxy coated aluminium frame complete with epoxy coated zintec sheet enclosure panels. MOTOR Motor 460V 4 pole. TEFC Explosion Proof Class I Group C & D, Class II Group F & G T3 complete with thermal protectors. Inverter Duty for variable torque application. FAN SPEED CONTROL Fan speed can be adjusted to suit filter condition via the frequency inverter located in main control panel. LIGHTS Location 120v Twin fluorescent (PL tube) fitting for hazardous locations Class I Div.1/2 - Groups C + D Class II Div.1/2 - Groups E, F + G Mounted behind acrylic diffuser in rear bulkhead MAIN CONTROL PANEL Location Electrical control panel rated NEMA 12 Remote sited in Safe Area. Not on booth chassis. LOCAL OPERATOR STATION The local operator station consists of : Explosion proof surface mounted unit complete with stop / start pushbutton. UL approved Class I Div 1 and DW2. Class II Div 1 and Div 2. Class III NEMA 4 X. Extended operator functions are available - see special features section if applicable. POWER RECEPTACLES None included MOTOR DISCONNECT SWITCH Location Adjacent to motor INSTRUMENTATION Pressure transmitter / pressure switches - for inclusion see special features section if applicable. WIRING HARNESS Located 25 feet or less away from booth The booth will be wired from the ETL control panel to all electrical components supplied by ETL, this includes: Lights, motor and local operator station. Site reconnections by Extract Technology. The above electrical equipment requires a supply of: 460V, 3 phase, 60Hz, earth. Mains connection to the booth control panel is excluded from our scope of supply -6- Client : Schering Plough Site: Union, NJ Q16399 (Rev4) Date: 10 Feb 2004 ETL Engineer: Eric Ferguson STANDARD SPECIFICATION FILTRATION CODE 12B Three stage filtration with “safe change” Fine Dust & HEPA filters, and ceiling mounted HEPA Filters for Recirculatory airflow SUPPLY AIR Volume: By Client’s System 8434 m3/hr (4964 CFM) SUPPLY AIR FILTER Ceiling HEPA Filter Efficiency : - EN1822 - IES-RP-CC001.3 (HEPA & ULPA) Classification: - EN1822 - IES-RP-CC001.3 FIRST STAGE Efficiency : - Ashrae 52.76 & EN779 Classification : - EN779 Case Construction : SECOND STAGE Efficiency : - EN1822 - Sodium Flame to Ashrae 52.76 Classification : - EN1822 Case Construction : On site testing : EXHAUST AIR Volume: INSTRUMENTATION Option for Visual and Audible Alarms on all Gauges 99.995% minimum to MPPS 99.999% minimum on 0.3 micron H14 Type 'D' Anodised aluminium with gel seal location Epoxy coated to both sides of filter Filter integrity may be tested on site to 0.01% penetration High capacity Fine Dust Filter safe change type : bag-in / bag-out 93% F8 Galvanised Steel case complete with EPDM seal. Mid Stage HEPA Filter – safe change type : bag-in / bag-out 99.995% 99.997% H13 Galvanised Steel case complete with EPDM seal. Ability to carry out filter integrity testing after HEPA Filter to 0.03% penetration. To be exhausted to Client’s System 8855 m3/hr (5212 CFM) Magnehelic differential pressure gauges. Easy to read 120mm gauges marked up with red and green safe work segments to monitor: (i) Supply airflow (i) Exhaust airflow (ii) Fine dust filter condition (iii) HEPA filter condition -7- Client : Schering Plough Site: Union, NJ Q16399 (Rev4) Date: 10 Feb 2004 ETL Engineer: Eric Ferguson POWERED, AUTOMATED ROLLER CONEYORS AND TURNTABLE Product Flow through Conveyors and Turntable The proposed line comprises of one LHS infeed conveyor to a booth conveyor. This is positioned directly before the turntable. After sampling, discharge is directly to an outfeed conveyor to the warehouse. Support Floor Due to the height of the conveyors, a 2415mm x 3310mm floor elevates the operator to allow ergonomic access to the drums. Floor is manufactured using aluminium chequer plate for the decking and 304-grade stainless steel for the support frame Pallet Size The pallets have been considered as 1200 mm x 1200 mm with a maximum load of up to 1000 kg. Roller Dimensions The rollers would be 76.2 mm (3") diameter on a 303.2 mm (8") pitch. Length Infeed Conveyor - Nominally 4 foot 8 inch powered section Booth Entry Conveyor - Nominally 2 foot powered section Turntable - Nominally 6 foot diameter with powered deck Discharge Conveyor - Nominally 4 foot 8 inch powered section Other Dimensions Width: Nominally 4' 2" inside frame Rollers: 3" diameter on a 8" pitch Height: 16" to top of roller General Construction 304-grade stainless steel for all internal conveyors and turntable. LHS infeed and RHS discharge conveyors to be coated, mild steel Finish: Dull polished Drives Suitably rated, Leeson/Motovario, geared motor units to NEMA standard and US electrical specification Class 1, Div. 1, Groups C& D and Class 2, Div. 2, Groups F & G within the booth and on the RHS discharge conveyor. Non hazardous area motor on LHS infeed conveyor Supply: 480 V, 3 phase, 60 Hz - to be confirmed Speed: 36 feet per minute - to be confirmed Controls: Included Notes Includes covers over any foot adjustment studding within booth. Includes covers over motors within booth. Turntable designed with slip-ring arrangement to enable continuous rotation by 90-degree increments. However due to the nature of this design, hose down of turntable is not permissible. -8- Client : Schering Plough Site: Union, NJ Q16399 (Rev4) Date: 10 Feb 2004 ETL Engineer: Eric Ferguson POWERED, AUTOMATED SLIDING DOORS (2 TOTAL) Product Flow through Sliding doors A pallet on the infeed conveyor will pass though a sensor on the LHS Sliding door, causing the door to open. Once the pallet in passed to the Booth entry conveyor and then onto the turntable, the LHS sliding door will shut. When all sampling operations are finished with the drums inside the booth, the pallet on the turntable will activate the RHS sliding door to open. Once though to the Discharge conveyor, the RHS sliding door will close. Doors may be manually activated by push to open/close switches. Note: door control panels to be remotely located in safe area. Door Opening 5’ 5”W x 8’ 0” H Electrical Classification RHS Sliding (looking into booth) door will have Class 1 Div 2 rated motor, sensors and switches LHS Sliding (looking into booth) door will have Class 1 Div 2 rated sensors and switches only. Door motor will not be electrically rated. 120 V or 220 V A.C., single phase with a 24 volt control circuit Vision Panels 24” x 36” laminates safety glass Construction 20 Ga., 304 #3/#4 Stainless Steel Door Panels with welded construction Kraft honeycomb core or urethane foam core as selected 12 ga. Carbon steel tubular steel interior framing 14 gauge stainless steel capping channels Track hood, header and jamb casing all stainless steel 304 #3/#4 finish Full perimeter neoprene seals -9- Client : Schering Plough Site: Union, NJ Q16399 (Rev4) Date: 10 Feb 2004 ETL Engineer: Eric Ferguson Equipment Cost Schedule Our price for the equipment proposed is set out below and this includes an English language Operation Manual:One (1) 2.5m DX Single Pass Downflow Solvent Booth as per Drawing: Q16399-GA2 including two automated sliding doors, all controls and alarm panel for the internal gauges. Price excludes roller conveyors, turntable and raised flooring $ 117,488 Roller Track & Conveyors/Turntable and raised flooring including all controls and integration costs $ 91,332 Factory Acceptance Test Report Sent to Schering prior to Equipment Shipment $ Included Packing of all equipment suitable for sea freight $ 4,915 DDP delivery to site for all equipment $ At Cost + 10% Supervision of installation by one CLS Engineer charged at $1,200/day including travel, accommodation and expenses but precluding airfare. Estimated at 5 days total ($6,000 estimate) $ Actual Days to be Invoiced On site commissioning and operator training by one CLS Engineer charged at $1,200/day including travel and accommodation. Estimated at 3 day total ($3,600 estimate) $ Actual Days to be Invoiced IQ/OQ Documentation $ 2,540 THE ABOVE PRICES ARE IN US DOLLAR AND ARE VALID FOR 60 DAYS - 10 - Client : Schering Plough Site: Union, NJ Q16399 (Rev4) Date: 10 Feb 2004 ETL Engineer: Eric Ferguson General Conditions of Contract Documentation Schedule The following documents have been included within the scope of the specified equipment: Provided by Carlisle Life Sciences Quantity Yes 1 Equipment General Arrangement (GA) Drawings Yes 1 Hardware Design Specification Yes 1 Pneumatic & Electrical Schematic Drawings Yes 1 Yes 1 Yes 1 Yes 1 Description As Ordered Specification / Functional Requirement Specification (FRS) Quality Plan Factory Acceptance Test (FAT) and FAT report Installation Qualification (IQ) documentation and site execution Operational Qualification (OQ) documentation and site execution (includes commissioning report) Commissioning Report (Not required if IQ/OQ is ordered) Equipment Data Book, including Operation and Maintenance (O&M) Manual. (hard copy) O&M manual (soft copy) Site validation / Operator Exposure Level (OEL) proving report NOTE: All documentation purchased will be to our standard format unless specifically detailed within special features of quotation. We will provide one equipment data book, which includes a section for the operation and maintenance manual. The equipment data book will contain all relevant material certification. Stainless steel mill certificates will be provided for product contact parts only (if requested at purchase order placement), these being hoppers, chutes, cones, etc. - 11 - Client : Schering Plough Site: Union, NJ 1. Q16399 (Rev4) Date: 10 Feb 2004 ETL Engineer: Eric Ferguson Delivery Date Delivery dates will be agreed between ourselves and the client. Following order placement a detailed programme will be issued highlighting key milestones within the contract schedule. 2. Terms of Payment Our standard terms of payment are as follows: Equipment: 20% of equipment value due with order placement 20% of equipment value with GA drawing approval 60% of equipment value plus all packing and delivery charges due with goods ready for delivery Site Services: 100% of installation charges due with completion of installation (or 30 days from delivery if delayed by client) 100% of commissioning charges due with completion of commissioning (or 60 days from delivery if delayed by client) Note: Client requested delays to delivery, installation or commissioning will result in invoices being issued on original programmed dates. 3. Project Engineers Site Visits We have included for 1 visit by our Project Engineer. Additional visits will be changeable at the current rate 4. Factory Acceptance Tests (FAT) This quotation does not include for a witnessed FAT of the specified equipment. This may be arranged at an additional price. If a full FAT is purchased then this would normally consist of the following: GA drawing review/verification. Functionality testing as required Airflow velocity test Smoke containment test Light level check Noise level check Documentation status review Site requirement review Dust in air testing / verification - optional at extra cost - 12 - Client : Schering Plough Site: Union, NJ 5. Q16399 (Rev4) Date: 10 Feb 2004 ETL Engineer: Eric Ferguson Mechanical Site Installation We can only commence site assembly when the work area is clean and dust free. Dust may contaminate the equipment sealing systems and filters, which could necessitate additional parts / filters, etc being required to ensure satisfactory operation. This would be chargeable. A preinstallation checklist will be issued prior to installation allowing you to confirm site readiness. Supervision of Installation on site has been estimated for a total of 5 man days (8 hours per day) depending on option taken. Should site condition delay the installation, we will charge lost hours at the current rate. Should we be unable to install the filters or ceiling screens due to site conditions, we reserve the right to charge for a return visit. Alternatively we may charge for additional site time during the commissioning / start up activities to carry out this work. 6. Equipment Commissioning Commissioning is planned to take place following completion of all client / sub-contractor interfaces with our equipment. A pre-commissioning checklist will be issued after installation allowing you to confirm site readiness. Commissioning on site has been costed for a total of 3 man-days (8 hours per day). Should site conditions delay the commissioning, we will charge lost hours at the current rate. 7. Operator Training Operator and maintenance training would be carried out on the same visit as equipment commissioning. Special training such as Operator Exposure Limit (OEL) verification, is subject to an additional price. 8. Variation Orders Variation orders that are agreed during the contract life cycle must be raised promptly to avoid delay in delivery / completion. Failure to provide written acceptance may postpone release of goods. 9. Client Requested Design Changes This quotation is based upon the specification and designs attached. Should the client request layout or specification changes after placement of purchase order we reserve the right to make a charge for additional design labour or materials associated with the required changes. Where a mock-up is provided for design review this mock-up represents the concept developed during our discussions with the project team. Where a purchase order has been placed for this design and the resultant mock up is found to require changes (at the client's request) then we will charge the additional materials and labour at the current rates. - 13 - Client : Schering Plough Site: Union, NJ 10. Q16399 (Rev4) Date: 10 Feb 2004 ETL Engineer: Eric Ferguson Delivery To Site The goods will be packed in bubble film or crated and delivered generally to coincide with the arrival of our installation engineers. This allows direct offloading and moving the equipment to the final location. 11. Hazardous Area Certification All ETL designs are compliant to the EC Machinery Directive – (98/37/EC), Low Voltage Directive (73/23/EEC) and EMC Directive (89/336/EEC). Also harmonized standards EN292 pt 1:1991, EN292 pt 2:1991 and EN60204-1:1998 outlined in our CE Declaration of Conformity. Non European designs/projects shall also be based on the above standards. Alternatives can be accommodated for National technical standards/specifications and client site standards upon request. (eg: UL, CSA) 12. Dispersed Oil Particulate (DOP) Filter Integrity Testing Filter integrity testing and certification to the relevant standard is available, and subject to an additional price. Exclusions of DOP testing during the commissioning engineers visit invalidates any claims regarding filter damage or leakage arising after our commissioning. We reserve the right to charge for return visits to site and delivery of commissioning spares should DOP be carried out by a third party after the main commissioning visit. 13. Storage In the event of goods being stored at our premises due to programme delays not of our making we reserve the right to charge for storage at the current rate. 14. Cancellation Charges 15. In the event of order cancellation after order placement, we reserve the right to charge 10% of order value or for all work carried out whichever is the greater amount, calculated on our standard hourly rates and usage of materials. Duty The above costs include for duties and taxes. - 14 - Client : Schering Plough Site: Union, NJ 16. Q16399 (Rev4) Date: 10 Feb 2004 ETL Engineer: Eric Ferguson Exclusions : Work Not Included In ETL Scope Of Supply a. Electrical connection to mains supply and all site wiring unless specifically mentioned. b. Building work, pipe fitters work or any other work not of our trade. c. Overtime working or work carried out at premium rates. d. Cranage and scaffolding unless specifically mentioned. e. We exclude all validation services unless specifically detailed in our proposal. This includes validation of computers, Programmable Logic Controller’s (PLC's) and weighing systems. Please advise in writing specific requirements for additional validation work required. f. Verification of field “safe work loads” from vendors equipment unless specifically mentioned. g. Scale set up and testing on site. (Should be provided at owners cost using local contractor unless specifically mentioned.) If you require further clarification of our scope of supply or details of work to be carried out by a third party contractor i.e. electrical / plumbing etc please contact our offices. Unless questions are raised prior to order we will assume our offer has been accepted and third party contractors have been organised by others. 17. Validity This quotation is valid for a period of 60 days from the above date. 18. Conditions Of Sale This offer is subject to our standard conditions of sale. 19. Warranty Should any defect or failure arise in the equipment supplied within 12 months of commissioning or handover of the equipment or within 18 months from delivery, whichever is the sooner, we will repair or replace the parts. No guarantees are made regarding expected filter life. The above guarantee is subject to the provision that no liability can be accepted for defects caused by using the equipment outside the limits of specification for which it was designed. We cannot accept any responsibility if failure of the equipment / component is due to neglect or inadequate service work carried out by a third party. - 15 -