Fractional Distillation

advertisement

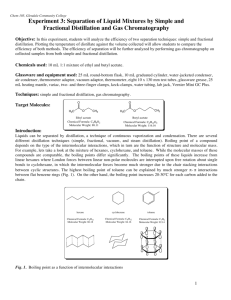

FRACTIONAL DISTILLATION Purpose: The purpose of this experiment is to use fractional distillation to separate a mixture of organic liquids. Discussion: Answer the following questions: 1. What is the theory behind general distillation? 2. Why are boiling chips added to the mixture before heating? 3. Why are glass beads or copper turnings inserted into the vertical condenser? 4. What is the difference between simple and fractional distillation? 5. What are some of the major applications of fractional distillation? Below is the general apparatus setup for a fractional distillation: Thermometer Ring Stand Thermometer adapter Three-way Clamp adapter Narrow condenser Vacuum adapter Clamp Clamps Wide condenser Ring Round-bottom Stand flask Heating mantle Beaker Wood block Objectives: In this lab, you will… 1. properly assemble a fractional distillation apparatus. 2. use fractional distillation to separate a mixture of organic liquids. Safety: Be extremely cautious as you assemble the apparatus. Get the apparatus approved by the instructor before you begin the distillation. Wear safety goggles at all times after the apparatus has been assembled. Materials: Organic glassware kit Use the 100 mL round-bottom flask (RBF) Glass beads or copper turnings 2 100 mL graduated cylinders Heating mantle with temp control Four red rubber tubes Three beakers, less than 250 mL Alcohol thermometer Two ring stands Four test tube clamps Boiling chips (tamer tabs) Cork round bottom flask holder Boiling point apparatus Chemicals: Unknown organic mixture Acetone (for cleaning) Procedure: 1. Place the 100 mL round-bottom flask (rbf) in the cork rbf holder. Carefully pour the unknown organic mixture into the 100 mL rbf. Add a couple boiling chips. 2. Use the diagram in the discussion to assemble the apparatus. Be sure to rinse the inside of each piece of equipment used with a small amount of acetone. Place glass beads or copper turnings in the vertical condenser. 3. Connect the bottom “in” stem of the condensers to the sink jet nozzles using a red rubber hose. Connect a red rubber hose to the top “out” stem of the condensers and place the hose in the sink so it can run into the sink drain. 4. Get your apparatus approved before moving to the next step. 5. Carefully turn on the cold water to both condensers. 6. Begin heating the mixture slowly by turning your heat to ~60%. After a few minutes, turn the heat up to ~90%. 7. Observe the boiling process and watch for a “vapor ring” as it passes up the vertical condenser into the 3-way adapter. Once the vapor hits the 3-way adapter and begins to condense in the narrow condenser, it will begin to drip into your first graduated cylinder. Collect 5 mL of distillate. Remove the graduated cylinder containing fraction 1, and immediately replace it with a second graduated cylinder to collect fraction 2. Pour fraction 1 into a small test tube, label it, and cork it. 8. Continue heating, and collect 10 mL of fraction 2. After that turn off the heat, and lower the heating mantle. Fraction 2 will be put into the organic waste container – it most likely contains a mixture of the two unknowns. 9. Fraction 3 will remain in the rbf. Once the apparatus cools to room temperature, pour fraction 3 into a small test tube, label it, and cork it. 10. Determine the boiling point of each fraction and record your results. Cleanup: Carefully disassemble the apparatus. Rinse each piece of glassware with acetone inside and out to clean it. Allow the components to dry, then place them back in the organic glassware kit. Return all equipment to its proper location.