simple and fractional distillation

advertisement

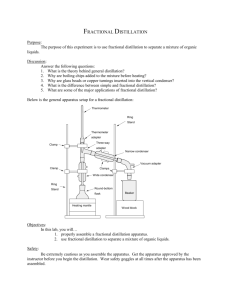

Chem-105, Glendale Community College Experiment 3: Separation of Liquid Mixtures by Simple and Fractional Distillation and Gas Chromatography Objective: In this experiment, students will analyze the efficiency of two separation techniques: simple and fractional distillation. Plotting the temperature of distillate against the volume collected will allow students to compare the efficiency of both methods. The efficiency of separation will be further analyzed by performing gas chromatography on collected samples from both simple and fractional distillation. Chemicals used: 10 mL 1:1 mixture of ethyl and butyl acetate. Glassware and equipment used: 25 mL round-bottom flask, 10 mL graduated cylinder, water-jacketed condenser, air condenser, thermometer adaptor, vacuum adaptor, thermometer, eight 10 x 130 mm test tubes, glassware grease, 25 mL heating mantle, variac, two- and three-finger clamps, keck-clamps, water tubing, lab jack, Vernier Mini GC Plus. Techniques: simple and fractional distillation, gas chromatography. O Target Molecules: H3C O O CH3 H3C Ethyl acetate Chemical Formula: C4H8O2 Molecular Weight: 88.11 O CH3 Butyl acetate Chemical Formula: C6H12O2 Molecular Weight: 116.16 Introduction: Liquids can be separated by distillation, a technique of continuous vaporization and condensation. There are several different distillation techniques (simple, fractional, vacuum, and steam distillation). Boiling point of a compound depends on the type of the intermolecular interactions, which in turn are the function of structure and molecular mass. For example, lets take a look at the mixture of hexanes, cyclohexane, and toluene. While the molecular masses of these compounds are comparable, the boiling points differ significantly. The boiling points of these liquids increase from linear hexanes where London forces between linear non-polar molecules are interrupted upon free rotation about single bonds to cyclohexane, in which the intermolecular forces become much stronger due to the chair stacking interactions between cyclic structures. The highest boiling point of toluene can be explained by much stronger !- ! interactions between flat benzene rings (Fig. 1). On the other hand, the boiling point increases 20-30oC for each carbon added to the chain. hexane cyclohexane toluene Chemical Formula: C6H14 Molecular Weight: 86.18 Chemical Formula: C6H12 Molecular Weight: 84.16 Chemical Formula: C7H8 Molecular Weight: 92.14 Fig. 1. Boiling point as a function of intermolecular interactions 1 Chem-105, Glendale Community College Simple distillation could be successful if the boiling points of compounds differ by a large amount (>100oC), or if a percent amount of the second component of the mixture is less than 10%. In this experiment, 1:1 mixture of ethyl acetate (bp 77.1oC) and butyl acetate (bp 120.6oC) will be separated by both simple and fractional distillation, and the results will be compared. Fractional distillation will be performed using glass beads as packing material. The efficiency of separation will depend on the surface provided by a packing material: the larger the surface is, the better is the separation. Fig. 2. Liquid-vapor composition diagram for a two-component mixture. The efficiency of separation will be then compared via two methods. First, the temperature of distillate will be plotted as a function of volume of distillate, using Excel program. When the separation is efficient, you should see flat plateau areas on the graph indicating distillation of pure fraction. However, if the boiling points of the components of the mixture are too close, then the graph will exhibit continuous increase of temperature during distillation process (Fig. 3). Fig. 3. Examples of Excel graphs of simple and fractional distillation The second method is the use of Gas Chromatography (GC) for analyzing the collected samples of distillate from both simple and fractional distillation procedures. GC chromatogram will be used to identify the components of the mixture and its percent composition. The number of peaks on GC indicates the number of components of the mixture separated. The time of elution can be used to identify each peak by comparing it with the time of elution of the reference compounds. Finally, the area under each peak will be used to calculate percent composition of each collected sample of distillate. By comparing the similar fractions from simple and fractional distillation, one can assess the efficiency of each distillation technique (Fig. 4). 2 Chem-105, Glendale Community College Ethyl acetate Butyl acetate Ethyl acetate Butyl acetate Retention time Percent composition of the mixture Fig. 4. Example of gas chromatogram In this experiment, Vernier Mini GC Plus will be used to analyze the fractions. See the instructions below. Experimental Procedure: Some tips from your fellow students: 1. Position your distillation apparatus as close to the water source as possible. 2. Connect the heating mantle to the variac and plug it to the electrical outlets above your glassware drawers. If you are using temperature controller on the bench-top, then plug the heating mantle directly to this controller. 3. REMEMBER to grease the joints and secure them with Keck clamps. Turn the greased joints of glassware until you see a clear unbroken ring of grease: this will indicate that the joints are greased and sealed properly to prevent the loss of heated vapors (Fig. 5). 4. Place a lab-jack underneath the heating mantel. If the rate of heating is much too fast, lower the jack and allow the flask to cool for a bit, and adjust the heat as necessary. Make sure to clamp the RBF in place, so it does not fall if the mantel is lowered. In fractional distillation, another jack (or wooden block) may be necessary to elevate the graduated cylinder closer to the outlet of the distillation apparatus. 5. There is only ONE two-finger clamp securing the apparatus, holding the RBF. This means that there is NO keck clamp on the RBF. 6. Position the rubber tubing away from the heating mantle to avoid burning. 7. Secure well the rubber tubing to the condenser and the water source. If the tube’s ends are ripped, stretch them gently and cut off the ripped parts. If the tubes are hard to connect, lubricate the ends with water. 8. Make sure that the water goes IN to the lower outlet and OUT from the upper outlet. 9. Thermometer tip should be barely below the side arm of the thermometer adaptor. 10. Maintain a constant rate of distillation at 1 drop per second. When the rate of distillation slows down, check the volume distilled, and if you’ve reached the highest boiling point solvent, slightly increase the setting of the variac to maintain the proper condensation. First Class Period: Simple Distillation Prepare a table for 20 readings of temperature and total accumulated volume in your notebook (make it a part of your prelab procedure before coming to the class). Label four small vials) as S-2, S-4, S-6 and S-8 and mark them in advance at 1 mL level. You can fill a same size test tube with 1 mL of deionized water and use it as your reference to mark the 3 Chem-105, Glendale Community College required volume on the rest of the test tubes. You will start collecting solution at 2, 4, 6 and 8 mL in the prepared test tubes. Each time 1 mL of distillate will be collected, corked, parafilmed, and left in the designated beaker for GC analysis. After collecting the last fragment, turn off and lower the heating mantle using your lab jack; allow the RBF to cool down (it’s hot). Do not attempt to run the process to dryness. Pipette in the ‘pot residue’ from the distilling flask and label it as PRS. 1. Place 10 mL of the 1:1 mixture of ethyl acetate/butyl acetate in the 25 mL round bottom flask (RBF) with a boiling chip (boiling chip is used to smooth the boiling). Place a 25 mL heating mantle around the round bottom flask. Set the apparatus as shown in Fig.5. Thermometer water-jacketed condenser water out Thermometer adaptor 50 mL distilling RBF vacuum adaptor water in zoomed-in position of the thermometer tip heating mantle graduated cylinder variac lab jack Fig. 5. Simple distillation apparatus 2. Use a 10ml graduated cylinder as a receiver. Place it as close as possible to the neck of the vacuum adapter. Start heating the mixture. Upon beginning of the refluxing, adjust the rate of distillation of about one drop per second (this is IMPORTANT because the rate needs to be constant throughout the entire procedure). 3. Record the temperature of vapors for the first drop of the distillate and continue recording the temperature for every 0.5 mL of the liquid collected. Do not attempt maintaining a constant temperature by constantly changing the rate of heating. 4. Upon collection of 1.00 mL of distillate in the graduated cylinder, quickly switch the cylinder with the labeled vial S-2 and collect 1ml of the distillate. Switch to the graduated cylinder and continue recording the temperature. 5. Continue collecting the distillate and recording the temperature. When the graduated cylinder is filled to 10.00 mL mark, dispose of distillate into a waste beaker and quickly place the cylinder back to the receiving position. 6. Continue distilling and collect in a similar manner 4th, 6th, and 8th mL of distillate in designated S-4, S-6 and S-8 test tubes. 7. Do not attempt to collect the last mL of mixture. Do not allow the distilling flask to go dry. Lower the heating mantle and let the RBF cool down. 8. Place the boiling chip in the designated container on the experiment cart. Rinse the RBF and the rest of the glassware in the hood with the min amount of acetone, then rinse it with soap solution, tap water and deionized water. Leave it in your drawer to dry until next class period. 4 Chem-105, Glendale Community College 9. Save the collected four fractions in a beaker: do not forget to cork and parafilm them properly. These samples will be analyzed later by GC. Waste disposal: dispose of organic waste in the designated NON-HALOGENATED waste container in the waste hood. Second Class Period: Fractional Distillation Before starting the experiment, prepare a table for 20 readings of temperature and total accumulated volume in your notebook (make it a part of your prelab procedure before coming to the class). Label four vials as F-2, F-4, F-6 and F-8 and mark them in advance at 1mL level. Pack your fractional column with glass beads. Assemble the fractional distillation apparatus. Since this apparatus is bulky, you can use a three-finger clamp to secure the water-jacketed condenser or the fractional column (Fig. 6). thermometer keck clamps thermometer adaptor water-jacketed condenser water in vacuum adaptor fractional column water out graduated cylinder receiver 2-finger clamp 50 mL RBF distilling flask variac heating mantle lab jack Fig. 6. Fractional distillation apparatus Repeat the entire above procedure. . You will collect the distillate for GC analysis at 2, 4 6, and 8 mL volume. You must record the temperature in 0.5mL increments. When the experiment is completed, return the used glass beads into designated container provided on the experiment cart, and wash the glassware as instructed above. Waste disposal: dispose of organic waste in the designated NON-HALOGENATED waste container in the waste hood. 5 Chem-105, Glendale Community College Third Class Period: Analysis of Fractions of the Distillate via GC All six samples collected from both simple and fractional distillations will be analyzed by GC (Gas Chromatography). In addition, a reference GC of the mixture of 1:1 mixture of ethyl acetate and butyl acetate, as well as the GC of pure components will be taken for the reference. The efficiency of the separation will depend on the purity of the fractions. The percent composition of components of the mixture in each fraction will be analyzed by using GC chromatograms and the results obtained for each fraction will be compared. You will then compare the efficiency of simple versus fractional distillation. 1. 1. Obtain a Vernier Mini GC Plus instrument from the balance room and a Fig. 7. Vernier Mini GC Plus Start temperature Hold time Ramp rate Final temperature Hold time Total length Pressure laptop from your instructor. Connect the instrument to the laptop through USB port. Each instrument comes with a glass syringe. 2. 2. Obtain vials with pure ethyl acetate, butyl acetate, 1:1 mixture of ethyl and butyl acetate and acetone. You will need less than a mL of each liquid. Acetone will be only used to clean the vial at the end of the experiment. 3. 3. Prepare the Vernier Mini GC for data collection. Set the TemperaturePressure values to: 35oC 1 min 10oC/min 65oC 1 min 4 min 9 kPa 3. Collect a 0.20 µL volume of ethyl acetate for injection. Once the Mini GC has reached the correct start temperature and pressure, the LED should turn green. Insert the needle into the injection port of the Mini GC. Please do not force the needle in too harsh: you might break the needle or puncture the septum. If you feel resistance while inserting the needle, gently turn it and then push in some more. Simultaneously, depress the syringe plunger and start data collection. Pull the needle out of the inject port immediately. 4. The data collection will end after 4 minutes or you can choose to end it early if you are satisfied that your compound has eluted completely. Analyze your chromatogram using Peak Integration. Analyze each chromatogram by choosing ‘Analyze’ option. Click and drag the cursor to select each peak, click ‘Add’, enter the name of the compound, and move on to the next peak. When finished, click ok. The chromatogram will have integrated peaks with the area under the peaks and the percent composition shown. 5. Print the chromatograms and attaché them to your reports. Print your chromatogram choosing ‘Chemistry 1’ printer from the printer menu. 6. Repeat Step 3 for butyl acetate, 1:1 mixture of ethyl acetate/butyl acetate, and the eight fractions you collected from both simple and fractional distillation. 7. Flush and clean the syringe with acetone. 8. Turn off the Mini GC. Return the instrument and the syringe into the box and place it back on the shelf. Excel Graphs of Simple and Fractional Distillation Plot the distillation temperature versus the distillation volume for both simple and fractional distillations (do not forget to include the volume of samples removed for GC analysis). Use a computer program such as Microsoft Excel for this plot. Draw a smooth curve through the data. Plot both simple and fractional distillation results on the same graph (see 6 Chem-105, Glendale Community College examples in above introduction section). Compare the results for both distillations and comment on the temperature behavior. Guidelines for writing report on ‘Simple and Fractional Distillation, GC” (20 pt) Name, partner’s name Date Title of the Experiment: Target Molecule: The report should be not longer than three pages, double-spaced (font size 12). Include name, partner’s name, date, and the title of the experiment. Please include the Excel graphs with the Please follow the instructions given below: Abstract: The abstract should state the purpose of the experiment, the methods used, and a brief summary of experimental results. Be very specific: introduction does not belong here. Target molecules: structures and names (you can hand-write this portion of the report) Results/Discussion: Tabulate temperature vs. mL distilled for your results for simple and fractional distillation and construct a graph for both techniques (refer to Fig. 3). Tabulate percent composition of components of the mixture obtained from GC. Attach GC printouts of all analized fractions. Retention time Composition S-2 S-4 S-6 S-8 F-2 F-4 F-6 F-8 Ethyl acetate Butyl acetate % Ethyl acetate % Butyl acetate Comment on your results and explain if your experimental results meet your expectations for the procedures performed. If not, provide a reasonable explanation. Comment on type of packing for fractional distillation, and suggest what could give you better separation. For GC analysis, state the number of peaks obtained, and if there are more than expected, provide a reasonable explanation. Conclusion: summarize the results and if you have any suggestions about improving the procedure for the future, comment on these. 7