Fractional Distillation Definition Final Draft

advertisement

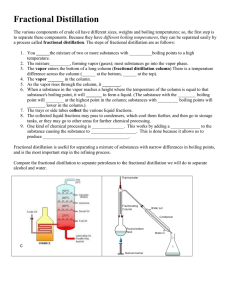

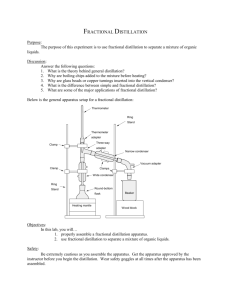

Alexander Shumski Fractional Distillation Definition Type: Process Definition Sentence Definition Fractional distillation is a process in which a solution containing two or more chemically distinct compounds with boiling points separated by a difference of less 25°C are separated by heat induced vaporization followed by condensation. Extended Definition Fractional distillation is used to separate organic solutions with boiling points that are too close to allow for a simple distillation. In practice, this will mean that the constituents of the solution have boiling points within 25°C of each other. The tendency of these solutions to boil rapidly in sequence means that the individual “fractions” of pure liquid are collected during the brief periods when only one of the components is boiling. Restrictions There are several conditions in which fractional distillation is rarely or never used, due to a combination of infeasibility or safety concerns. For instance, solutions that may contain peroxides are only distilled under highly controlled conditions due to the threat of explosive reactivity when purified. Certain solutions may also form azeotropes; mixtures that vaporize together at a specific temperature, forming a vapor with roughly the same composition as the original solution. If an azeotrope is produced any collected fractions will be comprised of a mixture very close to the intensive (not reliant on total quantity) azeotropic proportion of the two components in solution. As the fractional distillation process relies on obtaining separate, pure fractions, full separation does not occur under for these solutions. Another condition preventing fractional distillation is the potential reactive behavior of the mixture. For instance, carboxylic acids and alcohols will undergo Fischer esterification if sufficiently heated, producing esters. Many organics are heat reactive in some way, with the most extreme cases resulting in flash ignition or explosive gas evolution. As a result, the composition is always the primary restriction of what can and cannot be separated safely. Fractional distillation is almost always performed to purify miscible organic materials due to the low boiling points and common occurrence of experimental mixtures. It is a fast alternative to the more thorough separation provided by column chromatography when the components are known and the mixture is composed of a small number of miscible liquids. If the two solutions differ sufficiently in polarity or acid-base behavior, it is usually easier to perform an extraction, adding another limitation to the usefulness of fractional distillation. Process The process by which a solution is separated begins with an apparatus constructed with common organic laboratory glassware. The integral components of a fractional distillation column are a round bottom flask or glass bulb, a fractionating column, a condenser, and a heat source. While the layout may vary, all of these components are required for the distillation to occur. A diagram of a fairly typical burner based column can be seen below. The specific type of heat source is less important than the method of controlling the rate at which heating occurs. In the example, the heat source is a Bunsen burner; when the distillation is performed on more delicate solutions, the heat source is usually a controlled oil or sand bath. No matter what the heat source, the device must be capable of safely reaching a temperature higher than that of the second highest boiling point. At the bare minimum, the heat source needs to vaporize all other substances before the solution is a pure liquid; the final component does not need to be vaporized as it will be pure after the removal of all other fractions. The solution heats up to a controlled boiling point and generates a mixture of vapors due to a combination of the vaporization caused by boiling and the increasing vapor pressure of the other components. The mixture of vapor rises up the fractionating column, and the compounds with higher boiling points condense more quickly as the gas cools. As a result, only the compound with the lowest boiling point will reach the condenser. Once the boiling hot vapor hits the condenser, it is cooled by water running through the external compartment of the tube and the pure liquid is collected and seperated as the first fraction. The solution gets boiled away complete and the process repeats for the next component of the solution. As the goal of the process is to separate the mixture, it goes without saying that each liquid is captured in a separate container. If everything was done correctly, these fractions are pure and ready to be analyzed or used in other reactions. Sometimes the distillation is insufficient or the procedure was performed incorrectly, requiring a secondary purification method. In these cases, the distillation may be repeated or an alternative method of purification used to remove minor impurities. Microscale Version Fractional distillations can also be performed in microscale, using a greatly simplified version of the above set-up. The glass bulb is exchanged for a microscale test-tube, and a pipet becomes both the fractionating column and the condenser by systematically sucking up vapor and depositing liquid as fractions. This method is harder to control and yields only a small quantity of usable material, making it superior for purely analytical processes. Conclusions While it appears to be a fairly complex process, fractional distillation boils down to several relatively simple steps that are repeated for multiple components in solution. First, the solution is raised to the boiling point of the most easily vaporized substance. That substance is then boiled off, and separated from excess vapor through the fractionating column. The hot vapor is then cooled in the condenser by running water, and the fraction collected. Once the solution stops boiling, the fraction container is changed out for a new one, the solution heated to the next boiling point, and the process repeated until only pure substances are obtained. Recognize that fractional distillation is only one of many tools available to you when attempting to separate a homogenous solution and that all possible options should be considered before any separations are attempted. Due to the risk of lost product, distillations of this kind are almost never done on an entire sample, and a small to moderate amount of the crude solution saved as a backup. Much in the same way that samples are kept safe, the safety of the people performing these experiments is always top priority. Before and after every successful fractional distillation, the components are handled carefully and any unwanted results removed via proper laboratory waste disposal systems.