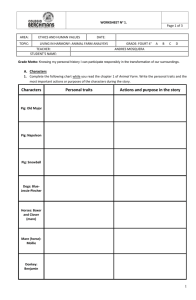

EIS Eulie - Harden Shire Council

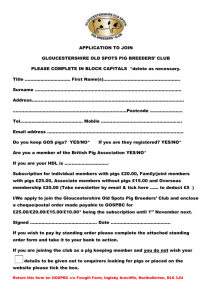

advertisement