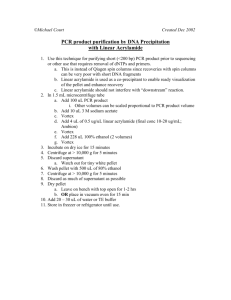

SOP 10 Ethanol preciptation

advertisement

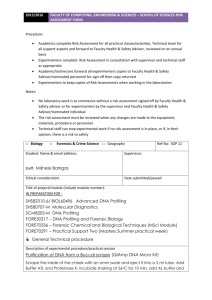

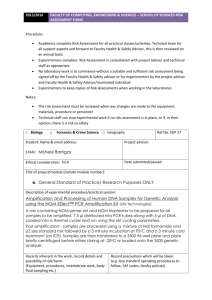

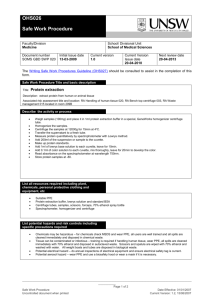

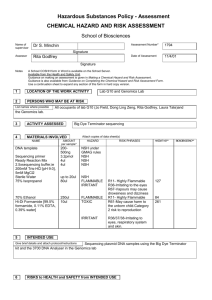

2015/2016 FACULTY OF COMPUTING, ENGINEERING & SCIENCES – SCHOOL OF SCIENCES RISK ASSESSMENT FORM Procedure: Academics complete Risk Assessment for all practical classes/activities, Technical team for all support aspects and forward to Faculty Health & Safety Advisor, reviewed on an annual basis Experimenters complete Risk Assessment in consultation with supervisor and technical staff as appropriate Academic/technicians forward all experimenters copies to Faculty Health & Safety Advisor/nominated personnel for sign off then copy returned Experimenters to keep copies of Risk Assessments when working in the laboratories Notes: No laboratory work is to commence without a risk assessment signed off by Faculty Health & Safety advisor or for experimenters by the supervisor and Faculty Health & Safety Advisor/nominated individual The risk assessment must be reviewed when any changes are made to the equipment, materials, procedure or personnel. Technical staff can stop experimental work if no risk assessment is in place, or if, in their opinion, there is a risk to safety □ Biology □ Forensics & Crime Science □ Geography Student: Name & email address: Ref No: SOP 10 Supervisor: Staff: Mishele Barrigas Ethical consideration: No ethics declaration Date submitted/passed Title of project/module (include module number): IN PREPARATION FOR - SHS80706-M DNA Techniques SHS82310-6/BIOL60496 Advanced DNA Profiling SHS80253-5 Genetics & Cell Biology SHS80209-5 Forensic Genetics FORE50317 DNA Profiling and Forensic Biology FORE70336 Forensic Chemical and Biological Techniques (MSci Module) FORE70291 Practical Support Two (Masters Summer practical week) General/ Technical procedure Description of experimental procedure/practical session Ethanol precipitation and Re-suspension of Extension Products for DNA Analysis using the 3500 Genetic Analyser Transfer PCR product to a 1.5 ml tube before adding PCR water and 95% ethanol. Vortex and incubate at room temperature for 15 minutes. Centrifuge for 20 minutes at maximum speed. Remove supernatant and add 70% ethanol to wash pellets and vortex briefly. Centrifuge for 10 minutes and remove supernatant. Load tubes into the vacuum centrifuge (tube lid open) to dry. Ensure no residual ethanol remains in the tube before re-suspending pellet in 10 µl of HiDi formamide. The entire volume is then transferred to a 96 well plate. Storage at -20oC or loaded directly onto the 3500 genetic analyser. Hazards inherent in the work, record details and possibility of harm: (equipment, procedures, invertebrate /environmental samples, body fluids) Record precautions which will be taken: (e.g. Any standard operating procedures to follow, SAF codes, faculty policies) Electrical hazard: microcentrifuge, vacuum centrifuge, vortex. All equipment is annually tested. Formamide is toxic Formamide is used in very small volumes, with exposure times kept to a minimum COSSH assessment (harmful substances) Minimum handling precautions Toxicity data: Hazardous to the aquatic environment (HAE) Acute toxicity (T) Gases under pressure (GUP) Corrosive (Corr) Explosive (E) Flammable (Fl) Caution ‘© Oxidising (O) Longer term health hazards (LTHH) Fume cupboard (F) Safety glasses (SG) Microbiological cabinet (Cab) Laminar flow cabinets (LF) Gloves (GL) Face mask (M) Respirator (R) Other All INFOMRATION CAN BE FOUND ON MSDS (MATERIAL SAFETY DATA SHEETS) ON THE INTERNET OR SCIENCES CHEMICAL DATABASE ON-LINE OR WITHIN EACH OF THE LABORATORIES 2 Chemicals involved (including Products): Toxicity data as above: Minimum handling precautions: Quantity to be used: ml/g/% solution PER REACTION 32 µl 200 µl 10 µl 8 µl 10-50 µl 95% ethanol 70% ethanol Hidi formamide PCR water PCR product C, Fl C, Fl T, C - Gl, SG Gl, SG Gl, SG Gl Gl Microorganisms: Classification: Minimum handling precautions: Do any of the above substances have a workplace exposure limit (WEL) please state value and precautions: YES OES 1000ppm/8Hr TWA (ethanol) Disposal information (How will all reactants/products be disposed of?) Waste ethanol to be stored for collection by a chemical disposal company. Formamide will be treated as hazardous waste and safely stored for disposal by a specialist company. Have you checked all reactants are not hazardous to the environment? YES Any special conditions specified as part of the permission to carry out the work/procedure and actions needed to minimise risk e.g. adherence to HTA or body fluid policy 1.52, completion of fieldwork risk assessment etc. None Supervisor/Academic comments: (Any disability issues to be aware of?) Staff/Supervisor - What level of risk do you assign with this work? High Medium Low Date: 4 September. 2015 Faculty H&S approval Date of Review Date: September 2016 3 4