INSTRUCTIONS TO AUTHORS FOR THE PREPARATION

advertisement

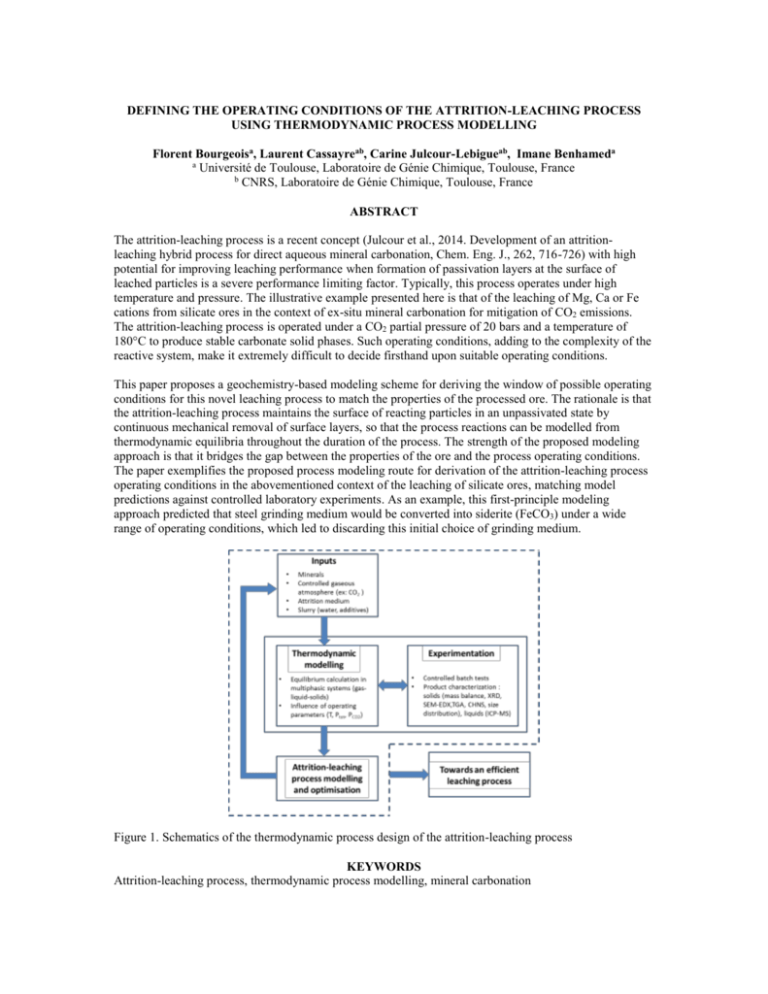

DEFINING THE OPERATING CONDITIONS OF THE ATTRITION-LEACHING PROCESS USING THERMODYNAMIC PROCESS MODELLING Florent Bourgeoisa, Laurent Cassayreab, Carine Julcour-Lebigueab, Imane Benhameda a Université de Toulouse, Laboratoire de Génie Chimique, Toulouse, France b CNRS, Laboratoire de Génie Chimique, Toulouse, France ABSTRACT The attrition-leaching process is a recent concept (Julcour et al., 2014. Development of an attritionleaching hybrid process for direct aqueous mineral carbonation, Chem. Eng. J., 262, 716-726) with high potential for improving leaching performance when formation of passivation layers at the surface of leached particles is a severe performance limiting factor. Typically, this process operates under high temperature and pressure. The illustrative example presented here is that of the leaching of Mg, Ca or Fe cations from silicate ores in the context of ex-situ mineral carbonation for mitigation of CO2 emissions. The attrition-leaching process is operated under a CO2 partial pressure of 20 bars and a temperature of 180°C to produce stable carbonate solid phases. Such operating conditions, adding to the complexity of the reactive system, make it extremely difficult to decide firsthand upon suitable operating conditions. This paper proposes a geochemistry-based modeling scheme for deriving the window of possible operating conditions for this novel leaching process to match the properties of the processed ore. The rationale is that the attrition-leaching process maintains the surface of reacting particles in an unpassivated state by continuous mechanical removal of surface layers, so that the process reactions can be modelled from thermodynamic equilibria throughout the duration of the process. The strength of the proposed modeling approach is that it bridges the gap between the properties of the ore and the process operating conditions. The paper exemplifies the proposed process modeling route for derivation of the attrition-leaching process operating conditions in the abovementioned context of the leaching of silicate ores, matching model predictions against controlled laboratory experiments. As an example, this first-principle modeling approach predicted that steel grinding medium would be converted into siderite (FeCO3) under a wide range of operating conditions, which led to discarding this initial choice of grinding medium. Figure 1. Schematics of the thermodynamic process design of the attrition-leaching process KEYWORDS Attrition-leaching process, thermodynamic process modelling, mineral carbonation

![[Zr(C 2 O 4 ) 4 ] 4](http://s3.studylib.net/store/data/006964769_1-29aedaf41342f4132b60bdeb351827c4-300x300.png)