Hamilton Farm Visits background - IFAJ Congress New Zealand 2015

advertisement

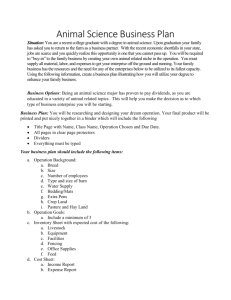

HAMILTON FARM VISITS - BACKGROUND GENERAL (1) WEDNESDAY McGrath Nurseries: species developer www.mcgrathnurseries.co.nz McGrath Nurseries Ltd is a fruit tree nursery established in the Waikato in 1980. It grows around 350,000 fruit trees and 750,000 rootstocks annually on 109 hectares. The main crop grown is apple trees, however McGrath Nurseries Ltd supplies 95% of New Zealand’s cherry trees and 75% of the apricot trees. It is one the biggest, or depending on the year, the biggest, fruit tree nursery in New Zealand. McGrath Nurseries is known for introducing new varieties, varietal Intellectual Property Management and technology innovation. It focuses strongly on the customer and its business has expanded to vertically integrate the production systems. McGrath controls who grows the trees, how many are grown, who sells them, who buys them, and at what price. Owner Andy McGrath searches the world’s breeding programmes for new fruit varieties that will enhance the value chain in the New Zealand market. Varieties are then imported, tested and promoted in New Zealand, and more recently worldwide, for the benefit of breeders, growers, and the business. McGrath Nurseries specialise in exclusive license arrangements between owners, growers and marketers which means varieties are protected for the owners and gives them accurate royalty payments. McGrath Nurseries has imported Cornell Geneva rootstocks from Cornell University in the USA, giving New Zealand growers naturally bred, multi-disease and pest resistant rootstocks with high yield efficiency. It has imported and developed the Honeycrisp apple from University of Minnesota in the USA, established a fruit growing region in the Timaru area of the South Island which exports the fruit to the USA in their off-season resulting in high returns back to the NZ grower, and it’s developed the KORU® Brand, a chance seedling discovered on the South Island of New Zealand, into a world variety with production to date established in New Zealand and USA (www.koruapple.co.nz). Livestock Improvement Corporation: co-op dairy breeder LIC is a co-operative of over 10,500 dairy shareholder farmers (the vast majority of the dairy industry in New Zealand). A specialist in artificial insemination, it is one of the agricultural sector’s largest investors in R&D and new product development – more than $25m annually, or 11% of revenue. Three out of four inseminated cows on New Zealand’s dairy farms are sired by LIC bulls Five million straws of fresh semen are despatched for insemination all over New Zealand during the mating season (135,000 straws on peak day). 827,000 DNA or milk samples are analysed annually for disease identification, gene testing and parental verification samples 10.7 million milk samples analysed by the herd testing service each year from 8100 herds. LIC’s goal is to deliver service and solutions that enable it to be a $1 billion revenue cooperative by 2025. GENERAL (2) WEDNESDAY Charlie Lea: rural entrepeneur cambrilea@gmail.com Charlie and Helen Lea run three rural-based businesses: a sheep and beef farm, contract weed spraying business and native plant nursery and planting business. Sheep and beef farm: The couple runs, as far as possible, a sustainable business with a low carbon footprint. On their 225 hectare sheep and beef property, which is an equal mix of flat, rolling and steep land, they run a closed flock and herd which means all the sheep and cattle are born on the farm, grow up on the farm and leave for the meat works. It’s a property they’ve been on for 11 years. Charlie grew up on a small beef farm and Helen is from a large sheep and beef farm. The farm has 2800 stock units, wintering 800 ewes and 250 hoggets. Both ewes and hoggets are put to the ram, resulting in 1400 lambs. Charlie doesn’t do a lambing beat and achieves 145% lambing. They run an on-farm hereford yearling bull sale where this year the average price was $2090. They gross $1400/ha with costs between $500 and $600/ha. They produce 300 kg carcass weight/ha, 180 kg is sheep meat and wool, the rest is beef. All stock are strictly grass-fed with no bought in product. Lambs are sold to Te Kuiti Meats which has a contract supplying the Wholefoods group in the United States. The wool is sold to Elders Primary Wool because it has a Just Shorn brand which sells New Zealand crossbred wool to carpet manufacturers in the USA. The name Just Shorn was developed to help educate overseas people who didn’t realise sheep didn’t need to be killed in order to provide a wool clip. The farm has 2.5 km of waterways. They have just put in 2.5 km of 8-wire fencing. 5700 native trees have been planted, with plans to plant a further 5000 every year. Steeper land has been fenced off for sheep, with easier country available for cattle. An oak tree has been planted in 30 paddocks giving stock shade and food for bees. Long-term, Charlie wants similar trees in every paddock. The farm has 17 ha of native busy which is fenced off. Farm fertility on the easy country is good, so only given maintenance levels of superphosphate annually. Charlie and Helen run the farm. They have three young girls, Chelsea (7), Sophie (5) and Georgia (20 months). Contract weed spraying: Eighteen years ago, Charlie set up a contract weed spraying business. Sheep were starting to be replaced by cattle on farms and he could see weeds would start getting out of control, so formed a company to combat them. He pioneered a system, which uses hand guns and hoses on 4 x 4 spray rigs. They apply 1.5 million litres of chemical mix a year and because of their application method which spot sprays, they use only 20% of the chemical per hectare compared with the more common blanket spraying approach. This protects waterways and is more environmentally friendly. His clients include sheep, beef and dairy farmers. A wind farm, Landcorp and utility companies. Twelve staff work for the business. Native tree planting and nursery: This business evolved out of the weed spraying business five years ago after clients asked if they could plant trees as well as spray. Trees were initially bought in, but because Helen has landscaping and nursery knowledge, so in order to have a guaranteed supply of tree seedlings, they set up a native tree nursery on their farm two years ago. This business keeps the 12 weed spraying staff employed over the three wet winter months when they plant 80,000 native trees for farmers and other landholders such as Fonterra which has farms beside its factories. The nursery has 17 species of native trees with over half being trees for bees to provide nectar and pollen between October and June. In the future Helen will be doing more riparian planting plans for farmers as these will be required by regional councils for environmental protection. Simcro : Global animal health delivery systems http://simcro.com/ Simcro is a Hamilton-based firm, which is a world leader in the design, development and packaging of devices which deliver animal health products, e.g. oral drench guns, vaccination guns and chemical pour on equipment. The products are mainly used in the sheep, beef, poultry and pig industries. Farmers are the main end users of the application devices, however they are often sold to multinational animal health companies who supply them along with the animal health product. Simcro drove the shift from metal application devices to well engineered plastic devices. Hamilton is ideally set up for this as it has very good plastic injection moulding firms. The company has a sophisticated engineering department with 12 design engineers. Something as simple sounding as getting product out of a tube, isn’t. There is a lot of engineering required to get a product out of a pack, into a device and into an animal. Simcro custom develops products for specific company’s needs. Plastic application devices can be made in a company’s colour wave. It has made 49 different coloured devices, with the colour influencing the lifespan of the product. Simcro has manufactured devices for 20 years and is now primarily owned by a United States-run private equity company, Riverside. The firm has sales offices in UK and USA. It is in the process of expanding its presence in USA, is going into Europe and Latin America, in particular, Brazil. It has a strong presence in Australia. Simcro employs 150 people. RED MEAT: THURSDAY Lloyd Watkins: farming without subsidies Roxborough Farm celebrated 100 years of ownership by the Watkins family in 2011. What started as an undeveloped farm has been transformed into a stunning sheep and beef property with family history preserved on the place. Lloyd’s grandfather didn’t like sheep so used cattle to develop the land. He milked cows in the 1930s. The following generation expanded into sheep and purchased the neighbouring farms, converting from dairy to sheep and cattle. Roxborough is 210 hectares with 1770 Romney ewes, and up to 180 cattle. The angus cross cattle are all bought for beef production. There is a flurry of activity in early spring when 2600 lambs are docked all in one go. It requires the labour of family and friends and is quite a social event on the farming calendar with picnics carted up to the back of the property. The oldest lambs are about a month old when docked, some will only be days old. This practice is needed for animal welfare as it helps prevent fly strike because poo (dags) aren’t stuck to long tails. Research shows there is no growth check for the animals and the discomfort lasts for half an hour or so. The lambs are sold to meat company AFFCO and exported. Most lambs leave the farm at a weight ready for slaughter. The cattle go to Silver Fern Farms. Fertiliser in the form of super phosphate is applied annually. Some lime is applied, depending on soil test results. Tests are done every two years. Lloyd has farmed through the change to no-subsidy farming. He believes food miles are often used as possible trade barriers, but in fact, New Zealand farmers have a low carbon footprint because most lambs and sheep are grass-fed, and even with the transportation overseas, the footprint can be lower than US and European produce. He says the issue isn’t as clear-cut as one thinks. He is currently building a pond at the bottom of a valley. This is for aesthetic reasons but also for environmental protection as he has sheep yards in the bottom of a valley, which drains into a water course. The pond will collect that water and filter is before going off farm. There are no rules around water discharge from sheep farms in Waikato at present, but Lloyd believes this is the way of the future and he’s consciously doing the mitigation work now. With the incidence of droughts increasing, he’s now running fewer stock than in the past which means his environmental impact from them is less. He farms more conservatively he says in order to cope, but as sheep numbers have decreased, his lamb production’s increased. The ewe fertility is better and they are better fed, sometimes with silage during mating. His docking is 146% to ewes mated I.e. The number of ewes that went to the ram, to the number of lambs docked. Cattle are drenched arriving on the farm and all ewes are drenched pre lambing. Lambs go onto a drenching programme from late October until they are slaughtered. Lloyd says as he’s aging, his farming philosophy is changing. In the past he was keen to ‘push’ things because he could; now he’s going back to older fashioned methods and doing what suits him and the farm. He’s rolling with the punches he says and is prepared to change as needed, rather than saying “this is what I’ve always done.” Ian Scott: Oraka Deer Park. http://www.oraka-deer.co.nz/ Scott farms is a mixed enterprise of dairy, deer and maize growing. The farm has high value ash soils and is situated between Tirau and Matamata. Ian Scott is a large animal veterinarian primarily working for dairy farmers, but also handling animal welfare issues in the deer industry. He has four farming properties: a home block of 108 ha (58 ha milking platform, 8 ha forestry block, 42 ha deer), Lake Road block of 50 ha support (8 ha bulls and calves, 42 ha maize), Oliver Farm block of 70 ha running deer, and an Off-Farm block for replacement stock and heifers which he sells. The main farm produces 138,000 kg of milk solids off 58 ha, running 5.2 cows to the hectare. Ian runs his cows and deer under an integrated grazing regime. The deer maintain pasture quality in spring allowing for increased cow productivity and improved mating performance. The deer are exceptionally good at removing weeds and improving pasture density. Parasite challenge is the biggest problem for young deer, so using parasite free dairy pastures enhances deer performance and sustainability by reducing dependence on chemical endectocides. The deer operation produces 1.5 tonnes of velvet, 400 deer carcasses and 8 to 10 trophy deer a year. He recently exported New Zealand’s first ever air shipment of deer to Europe. He also has exported deer to China. The exports to Europe are to improve the trophy potential of European estates. The farms are complex to run and Ian finds, like many New Zealand farmers, that people arriving from overseas, particularly Asian countries, have the attitude, the work ethic and sheer mental agility and skills needed. He believes the shortage of skilled New Zealand workers has developed because local schools are telling children that agriculture has a limited future and to look for careers in other areas. He says sustainability and environmental protection are the new tomorrow and a lot of work needs to be done. However, he sees it very much as not just the farmers’ problem. He questions if he should be penalised for leaching a little too much nitrogen because he produces over twice the national average/ha for milk solids, when New Zealand needs export products to sell to increase the country’s prosperity. He improves his farms’ sustainability by running the two stock types in an integrated way. Fewer chemicals are needed for worm control and cows graze on maize ground over the major leaching period of winter and early spring where deeper maize roots will soon recover the lost N from deep in the soil profile. Nutrients from feed pad waste are recycled back into the maize paddocks which reduces the amount of bought in fertiliser needed. Effluent is irrigated on to the deer farm where N losses are low. He protects and enhances the physical environment by totally excluding stock from waterways and supporting the Lake Okoroire restoration project. This is a $120,000 project to restore the South Waikato’s only peat lake. As to the future, Ian Scott say, sadly, his farming venture is partly reliant on New Zealand’s red meat processing industry, and despite years of pressure to change, it has doggedly resisted farming attempts at reform and continues to under deliver financially. The current moves to try to reform the industry don’t appear to be working. He says the world needs red meat and there have been huge investments in genetics, smart farming systems, better feeding but it still doesn’t make money. He cannot counter the pressure that so many sheep, beef and now cropping farmers have faced before him, he either continues to expand his dairy operation or be reduced to a peasant on his own high quality asset. DAIRY THURSDAY John Fisher: adapting robot technology to a New Zealand pastoral-based setting John Fisher farms 320 cows on an 80 hectare flat farm just south of Hamilton. He produces 150,000 kgs milk solids. The young stock are grazed off-farm from four months old until they are 22 months. One hundred cows are grazed off-farm for 10 weeks over winter. He became interested in robotic milking when DairyNZ set up a green fields research robotic farm in 2001, and got serious about it when he was looking at re-fencing the farm. John thought about whether he should fence to suit robot milking for several years, finally concluding it was the future and he was keen to do it. He started robot milking with DeLaval equipment in March 2011. It has gone relatively well, the main issues in the first six months were around software settings and learning how it all worked. John calves all his herd in spring, which was an added pressure with all the usual calving issues, and training heifers to robots is more challenging than conventional systems. He is currently transitioning to a split autumn/spring calving. John also had to make changes to raceways to make the robot grazing system work, but the paddock layout remained the same. He runs a pasture-based, low-cost, high-stocking rate system to get the best utilisation of the pasture by the cow, however with higher genetic cows and dry summers and robots, he has drifted to a higher input system. His pasture management philosophy is to grow as much high quality pasture as possible, mowing it prior to grazing if required to get the correct residuals and increase cow intake. Purchased feed is a mix of palm kernel, dried distillers grain and wheat bran pellet to feed in the robots – he uses 65 ton per year , as well as straight palm kernel mixed with Nutriliq , a liquid dairy factory waste. He also uses maize silage and grass silage. Two years ago he stared making maize silage off two hectares, using shed effluent as the fertiliser. This is becoming a very popular way to recycle waste nutrients. He applies 250 kg nitrogen per ha, 75 kgs potassium per ha, 13 kgs sulphur per ha, per year. His on-farm environmental efforts are irrigating effluent on to 30 hectares rather than it eventually going from effluent ponds into waterways. He has the ability to store the effluent if the soil conditions are too wet to allow application, and he’s about to construct a roof over the feed area to reduce rain water in effluent and help cow comfort. Tracy and Wynn Brown: sustainable farming with a view to the future Farm size & contour 320ha (total area) less 10ha (retired from grazing) leaves 310ha (effective area) less 80ha (drystock & cropping) equates to a 230ha (milking platform) The farm is rolling contour and prone to summer drys. Milking platform is Kereone silt loam soil while drystock support area is Peria hill soil. Average rainfall is 1200mm/year. Herd details 700 to 720 cows (plus 180 heifer replacements) crossbred (12:4) herd producing around 260,000kgMS/yr. Fully internal (on-farm) system. AI runs for four weeks with a target of 95% submission rate at 3 weeks and 98% at four weeks. The bull goes out on 12 th November for six weeks, and the empty rate is 9%. Calving is compact with mean calving around 1st August (within 12 days of the start date). Farming philosophy Farm name is ‘Tiroroa’ meaning ‘extensive view’ or ‘view to the future’. Our aim is to run an economically and environmentally sustainable dairy farming business, maximizing production while minimising footprint. There are five keys areas that are important to us and our business:. 1. Environment – wise use of natural resources & proactive environmental stewardship. 2. People – encourage values of communication, contribution, development, wellness & balance. 2. Animal Welfare – high standards of animal welfare health & well-being. 3. Community –enhance, contribute and give back to our community. 5. Economics– drive to increase profit through increased efficiency & decreased waste. Pasture management System 3, a predominantly pasture-based system producing around 12.5 tonne DM/ha/yr plus 18ha maize silage grown on-farm (@ yield of 25 tonne DM/ha). The maize is fed in autumn and an additional 260 tonne of feed is bought in and fed through an in shed feeding system (fed to yield depending on age, production etc). Fertiliser policy The property is soil tested bi-annually. Soils are naturally high in potash and we have a philosophy of only applying what is needed to maintain Olsen P levels (approx 35 units P per annum). Around 100 units N are applied strategically to enhance our pasture-based system. Environmental work Trees have been planted and waterways fenced off on this property for over 20 years. There are approximately 13 wetlands and 12-14km of waterways in total. Around 90% of these were already fenced prior to the Clean Streams Accord introduction in 1990 as it simply ‘seemed the right thing to do’. There is also a reserve of native New Zealand bush which includes some rare native species. In 2014 a $250,000 effluent system with dual drying beds, a lined pond and sprinkler system with a pump and flow metre were installed to ‘future-proof’ the dairying operation. The aim is to gain maximum nutrient value from recycling effluent to grow pasture. Environmental awards & programmes 2001 Waikato Farm Environment Trust: Habitat Enhancement Award 2010 Waikato Ballance Farm Environment Awards Supreme Award 2010 PGG Wrightson Land & Life Award, 2010 Hill Laboratories Harvest Award Following on from our attendance at the Dairy Environment Leaders Forum in 2010, Tracy joined the organising committee and has been the Programme Manager for this event for three years. In August she was appointed Chair of the DairyNZ Dairy Environment Leaders Forum. The Browns are also members of the NZ Farm Environment Trust Alumni (Tracy is Secretary) and founding members of the Mangagpapa Catchment Care Group. Our background Wynn has a Bachelor of Agriculture degree from Massey University. He grew up on this property as the son of a sheep and beef farming family. After finishing at Massey he worked for JD & RD Wallace specialising in conversion work. He came home in 1994 to convert the home farm from sheep and beef to dairy. In 2004 the family purchased the neighbouring sheep and beef property and Wynn undertook what was effectively a second conversion. Wynn is passionate about education and the ‘co-operative spirit’ having given significant time to several industry and community groups. He is a Fonterra networker, LIC Shareholder Councillor, has taken part in several DairyNZ on-farm trials, is in his third term (9th year) as a Hinuera BOT member (including the last 2 years as Chair) and has coached rugby in the community for 10 years. Wynn has also been a judge in the Ballance Farm Environment Awards for the last 4 years, including being a Finalist Waikato Judge in 2014 and a Finalist Northland Judge in 2015. Tracy has a Bachelor of Agricultural Science from Massey University, a Postgraduate Diploma from the University of Waikato and is a Lincoln University Kelloggs Scholar. She grew up in town and then a lifestyle block in Northland. She worked in Wellington as an economist for the NZ Meat and Wool Boards Economic Service as a new graduate, but has also held positions in the field for Agriculture ITO, ASB Bank Ltd, DairyNZ and the NZ Farm Environment Trust. She is a BOT member for Matamata Intermediate, has held several roles in community organisations and coached hockey in Matamata for the last five years. In addition to her contracted role for DairyNZ and the Dairy Environment Leaders Forum, she is also taking part in the Agri-Womens Development Trust ‘Escalator’ 10-month leadership and governance programme for women in the agri-sector. They have four children aged 10 to 15 years. As a family they enjoy mountain biking, the bush and time relaxing in Northand where they can fish and enjoy all things to do with the sea! Other relevant information In 2009 a new 54 bale GEA Westfalia cowshed with electronic ID and walk over weighing was commissioned. The new cowshed significantly reduced milking times and increased labour efficiency. HORTICULTURE THURSDAY Sunfruit Orchards (Pick Mee): apples, pears and stonefruit. John Altham owns Sunfruit Orchards and is a second generation orchardist; his son is the third. Sunfruit is a grower, packer, shipper of primarily apples but also pears and stonefruit. They do all their own export including contracting shipping etc. Sunfruit focuses on direct supply to supermarkets around the world, preferring not to work with wholesalers. It’s main export markets are in the UK, Europe, Thailand, Indonesia, Singapore, Taiwan, China, and to Tahiti in the Pacific Islands. Some fruit is packed for USA as well. Fruit is unique in that further processing usually destroys value and the best value is to be sold fresh from the supermarket shelf. Domestically, Sunfruit sells apples directly to the supermarket chain Countdown. The block you are seeing is one part of their operation. A third of their production comes from Waikato, the rest from Hawkes Bay. In total Sunfruit has 330 ha of orchard: 80% apples, 10% pears and 10% stonefruit. This particular orchard is on Hamilton clay and was originally planted in 1962. Some of the blocks are in their third cycle. Sunfruit grows Royal Gala, Braeburn and Pink Lady on the block we are visiting, with the other blocks in Waikato growing also growing Granny Smith. They grow Purple Majesty plums and Scarlet O’ Hara peaches At present the pipfruit industry is strong and expanding at quite a rate. There are many different varieties being bred these days which overcomes the previous issues of only having one or two varieties. All Sunfruit orchards are certified to Global GAP (Good Agricultural Practice). They use IFP (integrated fruit production), which is a philosophy of spraying chemicals only when required. They only use insect growth regulators, rather than poison insecticides. Organic’ practices are incorporated in spray programmes where ever possible with their main philosophy to eliminate any harsh chemicals. They use the softest products available. New Zealand’s apple growers get strong R & D support through Plant & Food Research, and John uses th Crown Research Institute extensively. There is also a strong new variety breeding programme with both Plant & Food and some private programmes both in New Zealand and overseas. At present Sunfruit is trying to increase productivity using different orchard structures and utilising growth differently. The main threat to New Zealand’s apple industry is labour. New Zealanders are not keen to carry out some of the seasonal jobs – but the Government thinks we should solve the unemployment problem within New Zealand, says John. New Zealand does have a guest worker programme from the Pacific Islands, which is an excellent programme, but is restricted. As new varieties are developed, they will be targeted at certain niches in different countries. There is a strong swing to the Asian tastes of big, red and sweet. Having these innovative new varieties has, and will, continue to strengthen New Zealand’s marketing edge versus other Southern Hemisphere competitors. John Altham says they operate all their businesses on the basis that the customer is the consumer and they want to be as close to them as possible to ensure they are satisfying their needs as to nutrition, taste, crispness and value. PickMee is the marketing arm of the company. Balle Brothers - large market gardeners http://www.ballebros.co.nz/ Balle Bros is a leading grower, packer and processor of New Zealand produce, with eight major properties across the country. Its reputation has been built over 65 years supplying both domestic and international markets with vegetables such as cabbage, cauliflower, carrots, potatoes and onions. Growing began in Waharoa in 1995 and last year the company began developing a state-of-the-art potato store. A key feature of the store is its underground ventilation, assisting in maintaining the quality of the crop during storage. Once completed, the store will have the capacity to store 30,000 tonnes of potatoes. Balle Bros was incorporated in 1991 but the family has been growing potatoes since early last century. The Balle brothers’ great grandfather started growing potatoes after WW1. The business is a large operation, farming with 2400 hectares of potatoes and onions in Pukekohe, Onewhero, Pukekawa, Te Kauwhata, Matamata, Heretaunga, Ohakune, and Canterbury. Their potatoes are used for French fries, crisps and the fresh market. The onions are mainly exported. Balle Bros employ 400 staff with most of the crop being mechanically harvested these days. Very little is done by hand. On a seasonal cycle they plant early potatoes in April/May and they’re harvested in October. The main crop spuds are planted in September/October and harvested in March, April and May. The seed potatoes mainly come from the South Island. SCIENCE THURSDAY Gallagher https://am.gallagher.com/nz When Joe the horse decided to use the family car as a scratching post, it inspired Bill Gallagher (senior) to solve the problem by electrifying the car. Joe got the message and the concept for the world’s first ever electric fence system was born. That innovative drive remains at the heart of Gallagher today. Now an international company operating in over 130 countries, it is still pushing the boundaries every day. It works alongside customers to find the ground-breaking solutions that make farming lives easier and more enjoyable and their operations more efficient and profitable. With over 1000 people worldwide and centuries of combined in-market experience, we’re proud to be the global leader in animal management. Ligar Polymers: http://www.ligarpolymers.com/ Ligar makes materials (polymers) that remove specific contaminants and extract valuable materials from fluids such as water, oil, wine and juices. For example, in wine there are many unwanted flavour taints, such as cork taint (from yeast infections), smoke taint (from bush fires) or bitterness (many possible causes). They make a specific polymer that removes the molecule that causes the taint, which means the polymer will only bind and capture that molecule and leave the positive flavours untouched. It is like making a puzzle piece that fits only one piece of the puzzle, in this case the molecule which causes the taint in wine. They can then filter wine past the polymer. As the taint molecule passes by the polymer, it gets locked into the polymer and stops flowing through with the wine. The filtered wine at the end will have no taint. Another example is removing pesticides from foods. They develop materials to capture the specific pesticides, then filtering the fluid food past the materials which will bind with the pesticide and therefore remove it from the food. Looking at extraction, Ligar can also extract very high value materials from fluids. For example, it is developing polymers that extract materials from plants that can then be used in medicines. The material they use is a polymer which is coated onto tiny beads or bind into nanofibers for ease of use as a filtering media. The polymer is imprinted with a particular molecule (the target) so that the polymer, when it comes into contact with the target will bind to it. There is a different polymer for every target. Imprinted polymers have been made for many years at small scale. Ligar has developed a method which lets them make them on a large scale. They can be used to target many different types of organic molecules and metals. They are currently working with the tanning industry (capturing and recycling chromium), the wine industry (capturing and removing various taints and agro chemicals), mining companies (extracting and separating valuable rare earth elements), and many other industries removing pesticides, smells, flavours, etc, some of which are valuable and some contaminants. GENERAL THURSDAY Fonterra Te Rapa www.fonterra.com/nz/en/about/our%2Blocations/newzealand/te%2Brapa/te %2Brapa Fonterra’s Te Rapa manufacturing site, in north Hamilton, has long been a showcase for the New Zealand dairy industry. Established in 1967, Te Rapa produces more than 325,000 tonnes of milk powders and cream products for export every year. Located in the Waikato, one of New Zealand’s strongest dairying regions, the site processes more than eight million litres per day at peak – around 300 tanker loads – and accounts for about 20% of the cooperatives’s annual milk powder production. Cambridge Stud: www.cambridgestud.co.nz Cambridge Stud is New Zealand’s finest thoroughbred nursery. Owned by Sir Patrick and Justine, Lady Hogan, Cambridge Stud has been responsible for standing the greatest stallions to have ever stood in New Zealand, Sir Tristram and Zabeel (still active). Cambridge Stud has also been New Zealand’s leading vendor at the National Yearling Sales for the past 31 years and is internationally recognised for its excellence in breeding top animals. Cambridge Stud was established in 1975 and during the nearly four decades since has been progressively developed into a showpiece property, spreading over 1000 acres of the finest horse country New Zealand has to offer. Sir Tristram arrived at Cambridge Stud in 1976; it was the beginning of a stud career which at one time saw him as the world’s leading sire for individual Group One winners. When the curtain came down on his long and illustrious career, Sir Tristram left a record of 45 individual Group One winners. One of Sir Tristram’s 45 Group One winners was his son from Lady Giselle, Zabeel. Zabeel followed on in Sir Tristram’s footsteps as a world-class sire and to this day remains Australasia’s greatest active stallion. Zabeel has sired 41 Group One winners (to date); has been Australia’s Champion Sire twice. In the current season Zabeel is the leading Broodmare Sire in both Australia and New Zealand. (Zabell died on September 26) Sir Patrick Hogan gained his knighthood in 1999. Eight years earlier he was awarded the Companion of the Order of the British Empire. He was inducted into the Australian Racing Hall of Fame in 2005 and the New Zealand Racing Hall of Fame in 2006. Sir Patrick and Justine, Lady Hogan have been voted New Zealand Breeder of the Year on four occasions and in 2004 were voted New Zealand Owners of the Year. Other special achievements include the US Thoroughbred Times naming Cambridge Stud as the world’s leading stud in 2005 for percentage of stakes winners to runners for stallions standing at stud. In 2008, Sir Tristram was inducted in the NZ Racing Hall of Fame. DAIRY FRIDAY Fonterra Te Rapa Fonterra’s Te Rapa manufacturing site, in north Hamilton, has long been a showcase for the New Zealand dairy industry. Established in 1967, Te Rapa produces more than 325,000 tonnes of milk powders and cream products for export every year. Located in the Waikato, one of New Zealand’s strongest dairying regions, the site processes more than eight million litres per day at peak – around 300 tanker loads – and accounts for about 20% of the cooperatives’s annual milk powder production. Sue and David Fish: balancing multi-farm ownership fishsd@farmside.co.nz Sue and David Fish run three dairy farms in Eastern Waikato, near Morrinsville. Sue is a dairy farmer from Britain, David grew up on a family dairy farm in Waikato. They both love the challenge of rearing stock from birth, taking them through to full production. They enjoy the seasons, there’s always another one to plan for. They’ve bought, developed and sold several farms in the area and find it challenging and enjoyable developing plans to improve systems, implementing them and getting good results. Sue has a real strength in recruiting, managing and training staff, teaching them about all the aspects of dairy farming. The three farms are: Westmorland Estate, 122 ha milking 470 cows; Somerset Farm, 78 ha milking 300 cows; Longridge, 128 ha milking 500 cows. The cows are crossbred ‘kiwi’ cows, a mix of jersey and friesian. They also have two ‘support’ farms totalling 130 ha. This is where they carry their own replacement stock for two years. On these blocks they also grow 44ha of maize for maize silage which goes back into the home farms when needed to supplement the cows. They prefer to grow the maize themselves rather than purchasing it on the spot market. These support blocks are a point of difference for Sue and David Fish. It gives them total control over how their young stock are grown. Many dairy farmers send calves off-farm where someone else does the rearing. The main fertiliser is chicken litter from a boiler chicken operation. They spread it over the farms every six weeks. They also spray irrigate dairy shed effluent. Half of each farm can be spray irrigated. Liquid nitrogen and projib is used to boost growth in spring. Westmorland and Longridge farms both have three permanent staff – Somerset has two permanent staff and there is a relief milker/general hand who covers all three farms. Sue and David are also on the farms. David’s philosophy is TPP: thinking, planning and pricing. He says his TPP is better than the TPP (International Trade deal) the New Zealand Government is negotiating at present because his works. He says success comes down to thinking and planning very well, and working out how to make things work in a low payout environment. He says this can mean changing crops and feeding regimes a lot. (There are no specific environmental things being done on farm because it’s flat with no running waterways. It does have amenity planting of London Plane Trees. ) RED MEAT FRIDAY Wayne and Debara Derrick – quality calf rearers The Derricks’ farm is 26 hectares of mostly flat to rolling country with a couple of steep gullies. The main emphasis on the farm is calf rearing, although every year they rear 30-40 Angus and Hereford cattle and take them through to export weights. In spring they rear 850 friesian heifers for export. They rear the calves for a fee and a contract person buys all the calves, which are exported. This spring they are also running 50 wagyu cattle that belong to Firstlight Foods, a specialist company that exports the product to high value markets such as Japan. In autumn they will be running between 150 and 300 wagyu cattle for Firstlight Foods. Wagyu is a relatively new breeding option for New Zealand farmers, it’s a product known for its intra-muscular fat. They look a little smaller and less beefy than traditional beef breeds, so it has taken New Zealand farmers a while to get used to them. Calves arrive between four and 20-days-old. For two weeks they are raised in a barn on premium milk replacer and museli before being moved outside where they eat grass and are fed pellets and milk. All the calves are weaned at between 85 to 90 kgs. Friesian heifers leave at 95kgs and wagyu leave at 90kgs. Wayne doesn’t employ any staff; the farm is run with help from his wife Debara and oneyear-old Ella. They love working outdoors with animals and really enjoy getting the satisfaction they get from raising babies into big healthy animals. Wayne and Debara are a great team with on-farm roles that suit their different strengths. While not one of the biggest calf rearing operators in Waikato, they are bigger than average, striving for quality, not quantity. Being big users of milk powder, the ups and downs of the dairy industry impacts on their business. This season milk powder is a lower price than in recent years, which helps their finances. Alexander Farming Genetics: Middle Earth farming Alexander Farming Genetics is farming 560 ha in the central Waikato. The farm is run as an intensive breeding and finishing operation, wintering around 9000 su at over 17 su/ha. It regularly achieves a lambing percentage of around 150%. One of its main objectives is ewe efficiency, with these results being achieved from high performing medium weight ewes. It is the ability of the sheep to perform under a high stocking rate, withstand a FE challenge and recover from tough environmental conditions that is of most importance to the Alexanders. “We are currently initiating a lot of work in the area of molecular breeding values (DNA) with Zoetis and we see this as the next increase in productivity through increased genetic gain. We have also become leaders in the field of worm resilience, resistance and research, and with the help of AgResearch have now made a large investment into this area. We feel that this is one of the more challenging problems that New Zealand sheep farming faces in the years ahead.” The Alexanders’ property is the home farm of Hobbition – one of the film sets of The Lord of the Rings trilogy. HORTICULTURE FRIDAY Vilagrad Winery: old and new world winemaking. www.vilagradwines.co.nz Vilagrad Winery traces its history in New Zealand back more than 100 years. Its founding father was Croatian Ivan Milicich snr who arrived in New Zealand in 1893. He left his small village of Pogora on the Dalmatian coast behind, but he retained a deep abiding love for his homeland and people. These attributes continue to influence subsequent generations of his family in New Zealand. For over a decade Ivan snr worked as a kauri gum-digger and on contract jobs, saving to help his brothers emigrate, and to buy his own land. In 1906 he began to grow grapes on his small dairy farm at Ngahinapouri, Waikato, and in 1922 he obtained a license to make and sell wine. This was the beginning of a Waikato family business which is now in its fifth generation. The winery is known as Vilagrad, where the great-grand sons of Ivan Milicich snr make award-winning wines using both modern and traditional techniques. Each generation has brought changes and extensions to the family business.Current owners, Ivan's grand-daughter Nelda, and her husband Pieter Nooyen, replanted much of the vineyard with classic varieties of grape, as well as maintaining some of the traditional varieties. Vilagrad Winery continues to produce ports and sherries from their almost 100year-old vines planted by Ivan snr. Ivan snr’s three great-grandson's have their own label, '3 Brothers' which specialises in five different varietals, with the grapes being grown in five well-known regions in New Zealand. BBC Technologies: http://www.bbctechnologies.com BBC Technologies is a leading global manufacturer and supplier of advanced sorting and packing equipment. The company employs over 120 staff and is headquartered just outside of Hamilton, New Zealand. BBC Technologies’ heritage runs deep in the horticulture industry, having been founded in 1999 by the Furniss Family: owner-operators for over 25 years of Blueberry Country, New Zealand’s largest blueberry farm. Working with producers across the globe and closely with its sister company, BBC Technologies’ research and development team are able to constantly improve its electronic equipment. In 2015, BBC Technologies released the CURO-16 filling system, the world’s fastest filling machine. Servicing a large global footprint with markets in North and South America, Europe and Asia Pacific, BBC Technologies’ equipment is operated in more than 25 countries. SCIENCE FRIDAY Plant & Food Research Dr David Pattemore is a pollination scientist with Plant & Food and will be discussing its efforts to develop a range of pollination strategies for growers to choose from, including the most efficient use of honey bees, managed bumble bee colonies and utilising wild pollinators. Plant & Food Research's Pollination & Apiculture team has worked closely with beekeeping and horticultural industries for over two decades; optimising crop pollination and maintaining healthy honey bees. Current projects include developing an integrated control programme for the Varroa mite and developing techniques to manage bumble bee colonies for orchard-scale pollination. Dr Peter Schaare is the science group leader of Plant & Food’s Bioengineering Technologies Group that develops and applies physical technologies to support the growth of plant-based food industries and the manufacturing and exporting industries based around them. The group comprises engineers, physicists, chemists and plant physiologists and interacts strongly with other research groups both within and outside Plant & Food Research. He will be discussing new technologies for the assessment and treatment of fresh produce such as advances in vision grading and the use of volatiles for determining produce condition. AgResearch AgResearch is New Zealand’s largest Crown Research Institute (CRI) and partners with the pastoral sector to identify and deliver the innovation that is needed to create value for the country. It has approximately 800 staff spread across four campuses and farms in the Waikato, Manawatu, Canterbury and Otago. AgResearch plays a key role in delivering new knowledge and technologies which underpin the pastoral, agri-food and agri-technology value chains. We do this by working closely with sector partners and our strategy is outlined in our Statement of Corporate Intent. We are the lead CRI in the following areas: Pasture-based animal production systems New pasture plant varieties Agriculture-derived greenhouse gas mitigation and pastoral climate change adaption Agri-food and bio-based products and agri-technologies Integrated social and biophysical research to support pastoral, agri-food and agritechnology sector development. We work with other research providers and end-users to contribute to the development of the following areas: Biosecurity, land, soil and freshwater management Climate change adaption and mitigation Food and beverage sector (including foods for human nutrition and health, food technologies and food safety). This afternoon’s visit is to AgResearch’s new dairy goat research facility at its Ruakura campus. More detail on the facility can be found here http://www.agresearch.co.nz/news/new-dairy-goat-research-gets-underway-at-ruakura/ GENERAL FRIDAY Gallagher https://am.gallagher.com/nz When Joe the horse decided to use the family car as a scratching post, it inspired Bill Gallagher (senior) to solve the problem by electrifying the car. Joe got the message and the concept for the world’s first ever electric fence system was born. That innovative drive remains at the heart of Gallagher today. Now an international company operating in over 130 countries, it is still pushing the boundaries every day. It works alongside customers to find the ground-breaking solutions that make farming lives easier and more enjoyable and their operations more efficient and profitable. With over 1000 people worldwide and centuries of combined in-market experience, we’re proud to be the global leader in animal management. Dan Hinton: pushing the traditional NZ seasonal production system Dan Hinton farms just east of Hamilton in a small settlement called Eureka. He milks 550 friesian cows off 166 effective hectares. The farm has been in the Hinton family since 1914 when Dan’s great grandfather purchased it. Initially it was a dairy farm, converted to beef when Dan was very young, and then went back into dairy land when he left home at 17. Dan spent time overseas and working on other farms before having a serious accident. He thought he’d never farm again so started tractor and truck driving, before realising he wanted to still be involved in dairying, so in his early thirties he completed an agricultural degree at Lincoln University. He planned to become a farm consultant, which he did for a couple of years. His parents then gave him the chance to return home. Upon taking over the home farm as a sharemilker, he increased the stocking rate from 450 cows to 550, and moved production from 900 kg/milk solids /ha, to 1500 kgs/MS/ha. To cope with the increased cow numbers he buys in supplementary feed, but he keeps the cost structure low, at around $3.80 a kilo of milksolids. He says the key to a successful farm is maintaining pasture quality where the grass is well used and imported feed is only used to fill gaps. He spends a lot of time teaching his farm workers how to observe pasture and know when it is the best time to graze. He has converted the farm to be autumn calving because he believes that matches the cows’ feed demands to grass quality, rather than supply, as happens in spring calving herds. His motto is “fat cows are calving”, a saying which is even on his fiancee’s car licence plate. His main environmental project has been putting in a 4 million litre effluent storage facility, which lets him spray irrigate the effluent when the weather and soils are optimum. Some of the effluent is sprayed onto his maize or kale growing ground to boost P levels, the rest is sprayed onto pasture to encourage growth. Dan is working with the regional council to draw up plans to plant up low-lying, peat/swamp areas of the property. The farm also has many waterways so he is just beginning riparian planting. Dan employs a farm manager and one of his goals is to build up a skill base so there are options for business development, whether that’s finding another large sharemilking job for himself, or a small operation the farm manager could move onto. His financee also helps with milking, calving and farm work. Dan says the best part about farming is being able to disappear any time he wants because he has skilled, trained staff who cope when he’s not around. He says there’s always work ahead, every day is fun and enjoyable, and once you decide dairying is not a job, but what you do, you’re away. DAIRY SATURDAY Meyer Gouda: Champion cheesemaker. www.meyer-cheese.co.nz The Meyer Gouda Cheese story began in a tiny village in the South of the Netherlands. After visiting a monastery in Postel where monks were producing hand-made cheese, Ben and Fieke Meyer were inspired to try cheesemaking themselves. Independence, working close to nature and producing a good honest product, appealed to the young couple. They lived on a farm in a converted old chicken shed called Het Hok and at night after work they travelled to cheese farms to purchase second-hand equipment to carefully restore for the factory. All the work was done by hand and every cent they earned went into their cheese factory. They made their first Gouda cheese in 1976. In 1981, they applied to immigrate to New Zealand and eventually in 1983, they were also offered permanent residency in New Zealand. In 1984, Ben and Fieke arrived in the land of the long white cloud with three small children, Geert (4), Fieke (2) and baby Miel. The Meyers settled in Waikato , quickly setting up their cheesemaking business. Initially they struggled with the New Zealand milk as Kiwi dairy cows’ milk composition differed dramatically from milk in The Netherlands. Five years later they purchased their own farm to control milk supply, a decision paramount to the quality of their cheese production today. Meyer Gouda Cheese is now a fully-fledged family affair with the next generation at the helm. Miel took over as general manager of Meyer Gouda Cheese after Ben and Fieke retired in 2007. In August 2011, eldest son Geert came back from The Netherlands as head cheesemaker for Meyer Gouda Cheese. The family has 160 hectares and about 400 mostly Friesian cows, although they cross them with a Jersey occasionally for milk quality for the cheese. The factory takes up to 5000L of milk a day and the rest goes to the Fonterra co-operative. This system lets them collect the best of the season’s milk for cheesemaking. They make only Dutch Gouda style cheese, which is what the parents started making in the beginning. Over the years the Meyer cheese has won nearly every award possible and the family is extremely proud it has produced not only an award-winning product, but one that performs consistently year in, year out. Thanks to winning so many national awards, larger supermarket chains are now selling their product, as well as the specialty food stores and delicatessens that have always been an outlet for them. They also sell direct to people if it is a whole wheel. Four staff work fulltime in the business, with more coming on board during the peak periods. The cheese is mainly sold through distributors, which they like because it lets them concentrate on quality production, rather than sales. Two of the Meyer siblings work in the business and their partners work when they can, or when they’re needed, with their parents still helping out at food-shows and events. The other sister and her husband Bert run the dairy farm, so it is a true family business. The main growth market for the cheesemakers has been in the added value market. Previously their main market was wholesale and whole wheels, but now a lot of the product it cut into retail ready portions. Meyer Gouda Cheese has some impressive awards: 1994, Cheese of the Decade, 2012 Cheesemaker of the Year, 2013 Supreme Champion, 2014 Supreme Champion, 2015 Cheesemaker of the year. Fonterra innovation: session with Dr Jeremy at the Novotel Hotel. RED MEAT SATURDAY Colin Brown: Lake Farm Beef : paddock to plate beef www.lakefarmbeef.co.nz Lake Farm Beef is an artisan beef breeder with extremely calm cattle enjoying life on a 30 hectare, lakeside property. The operation’s mission is to breed an angus herd as good as anything in the world, specifically for eating quality, which means 1% marbling, tender, a large eye muscle and heavy carcass. They are currently recording the cattle so these goals are objective, and not subjective. Any animal that does not provide these traits after testing, will not be used for replacement breeding. Most replacement animals are embryo transfer progeny – using the highest recorded females mated to the world’s best bulls for these required traits. Lake Farm Beef sells prime beef cuts directly to consumers on-line. It also produces gourmet pies with the aim of producing the ‘best pies on the planet’ with large chunks of meat and chef quality recipes. The Browns see their operation as so much more than paddock-to-plate; rather conceptionto-consumption. It is very much a providence story – they only supply what they breed and raise. They do not buy in beef, or cattle to fatten. Beef + Lamb New Zealand’s Steak of Origin competition is a prestigious annual competition to find the best steak in the country. Every steak is tested scientifically and taste tested by a panel of judges. Lake Farm Beef has won both the champion breeding side of the competition and the champion selling side in recent years. Regardless of all the awards, Lake Farm Beef is very focused on making sure the animals are not only ethically raised, but have a great, stress-free life. Every animal is named; there are no dogs, and when animals go to slaughter, they always go in pairs, or threes, to make that final journey as stress-free as possible. This is extremely important to Colin and is a central driver. Rob Taylor : export lamb finisher Rob Taylor’s farm is 230 hectares of rolling to steep country. His stocking rate can vary quickly, but in the 2015 season he has 3000 lambs of mixed breed. He has between 250 and 300 hereford-friesian cross heifers, and steers. A big part of Rob’s business is lamb finishing, which means he buys in store lambs at 28 to 31 kilos live weight and sells them at 45 plus live weight. Lamb finishing means fattening the lambs ready for sale. They are usually on the farm for six to eight weeks, depending on the time of the year and feed levels. The lambs are rotationally grazed on 42 hectares of Chicory and clover, and rye and clover pastures, and drenched for internal parasites every four weeks. This is a very intensive lamb-finishing programme so animal welfare is second nature to Rob. If he requires extra advice he uses the local vet club. Lambs are docked for animal welfare purposes, it helps prevent fly strike and dags (dung that sticks to the wool). The aim of this farming property is to have the lambs on the farm for the shortest possible time. When they arrive on the farm, they are weighed and split into three groups. The heaviest ones are given priority feed and may only be on the farm for three weeks. Rob uses a Gallagher automatic 3-way drafter with computer operation, capable of moving 600 animals an hour. This is an important piece of equipment as it takes the guess-work out of whether the lambs are at the weight required for him to get a premium price. The farm’s records and physical structures such as the woolshed and yards are audited every three years to make sure they are kept up to a required standard. To maintain a high quality farm, Rob continually maintains and upgrades fences and recently he’s completed fencing all streams to keep cattle out. The Taylor farm backs onto the large Maungatautari Ecological Island reserve and some of his native bush is now in the reserve. He’s changed from using urea, to gribpro. This encourages grass growth but doesn’t leach N into the waterways the way urea can. Rob’s early life was spent on a dairy farm in Taranaki. His father bought this current farm when he was 12, and after attending an agricultural college until he was 17, he returned to work on the property and has been there ever since. Initially all the stock work was on horseback, now it’s all on quad bikes. They used to make all the fence batons out of their own native trees and now they buy them in. The original farm was about 60 hectares of bush, which they broke in by the back-breaking slog of slashing, chainsawing, burning and then grassing. SCIENCE SATURDAY CRV Ambreed https://www.crv4all.co.nz/ CRV Ambreed is part of the third largest artificial breeding company in the world with around 25% market share in New Zealand. It exports semen to South America, South Africa, Australia, parts of North America, the UK and Ireland. Currently close to 1.8 million straws of semen are distributed to domestic and export markets from its facilities each year. CRV Ambreed’s breeding programme focuses on producing long-lasting, productive cows. Emphasis is placed on increasing genetic gain for protein production while maintaining the size of the Friesian, emphasising efficiency and sustainability for farmers’ future herds, and improving shed traits, capacity and udders. Sires developed by CRV Ambreed breed cows that typically produce on average 450kg of milk solids each year and last for at least 5.5 lactations. In December last year, CRV Ambreed officially opened its new, purpose-built, world-class domestic and export-approved bovine semen production and logistics centre. The centre ensures CRV Ambreed can continue to meet the changing needs of the dairy industry, both within New Zealand and around the world. The centre houses a semen collection facility, a semen processing laboratory, storage space for export and domestic products, a warehouse with farmer AI banks and 38 hectares of grazing paddocks. Pastoral 21 Pastoral 21 Next Generation Dairy Systems is a five-year farm programme that aims to provide proven, profitable, simple, adoption-ready systems that lift production and reduce nutrient loss. It is a collaborative venture among DairyNZ, Fonterra, Dairy Companies Association of New Zealand, Beef + Lamb New Zealand and the Ministry of Business, Innovation and Employment, and managed by AgResearch. The programme has been set up in four regions to address issues relevant to that area. The visit will be to DairyNZ's Scott Farm, Hamilton Project goal: To show that an average Waikato farm could increase annual milk production by up to 200kg/ha with increased profit per hectare, while reducing nitrogen leaded from 35-50+ kg/ha per year down to 2030kg/ha per year. Project details: Since the start of the 2011/12 season, two 13ha farmlets have been compared. One represents a typical Waikato farm, with a stocking rate of 3.2 cows/ha. The other with a stocking rate of 2.6 cows/ha, represents a farm managed more efficiently. Prior to the visit to Scott Farm, two AgResearch scientists will background pastoral issues. Dr Stewart Ledgard is a Principal Scientist in the Land and Environment Section at AgResearch. He is internationally recognised for research in two areas: nitrogen cycling in pastoral farming systems and the development and evaluation of practical farm mitigation options to reduce nitrogen losses; and life cycle management, which targets resource use efficiency and environmental emissions efficiency across the life cycle of agricultural products. Recent focus has been on environmental footprinting of milk, meat and fibre products from agriculture in collaboration with primary sector groups. Stewart is also an adjunct Professor of the New Zealand Life Cycle Management Centre, Massey University. He will discuss: New Zealand pastoral farms focus on low-cost grazing systems but are also having to meet constraints on minimising environmental emissions. Major focus is on reducing nitrogen and phosphorus loss from farms to waterways. In an increasing number of lake and river catchments, this is associated with limits on per-hectare losses from farms, particularly for nitrogen. There is also recognition of our need to achieve a low environmental footprint of our products supplied into overseas markets. Research will be described on the environmental footprint of products using life cycle assessment, the main determining factors and effects of mitigation practices. HORTICULTURE SATURDAY McGrath Nurseries: species developer www.mcgrathnurseries.co.nz McGrath Nurseries Ltd is a fruit tree nursery established in the Waikato in 1980. It grows around 350,000 fruit trees and 750,000 rootstocks annually on 109 hectares. The main crop grown is apple trees, however McGrath Nurseries Ltd supplies 95% of New Zealand’s cherry trees and 75% of the apricot trees. It is one the biggest, or depending on the year, the biggest, fruit tree nursery in New Zealand. McGrath Nurseries is known for introducing new varieties, varietal Intellectual Property Management and technology innovation. It focuses strongly on the customer and its business has expanded to vertically integrate the production systems. McGrath controls who grows the trees, how many are grown, who sells them, who buys them, and at what price. Owner Andy McGrath searches the world’s breeding programmes for new fruit varieties that will enhance the value chain in the New Zealand market. Varieties are then imported, tested and promoted in New Zealand, and more recently worldwide, for the benefit of breeders, growers, and the business. McGrath Nurseries specialise in exclusive license arrangements between owners, growers and marketers which means varieties are protected for the owners and gives them accurate royalty payments. McGrath Nurseries has imported Cornell Geneva rootstocks from Cornell University in the USA, giving New Zealand growers naturally bred, multi-disease and pest resistant rootstocks with high yield efficiency. It has imported and developed the Honeycrisp apple from University of Minnesota in the USA, established a fruit growing region in the Timaru area of the South Island which exports the fruit to the USA in their off-season resulting in high returns back to the NZ grower, and it’s developed the KORU® Brand, a chance seedling discovered on the South Island of New Zealand, into a world variety with production to date established in New Zealand and USA (www.koruapple.co.nz). A passion for improvement through innovation, along with finding out what’s best for the customer, continue to be the driving force at McGrath Nurseries. Whitehall Fruitpackers: kiwifruit growers Mark and Robyn Gardiner of Whitehall Fruitpackers are among the earliest kiwifruit growers in the Waikato, a region that grows around 4% of Zespri’s fruit. The cold winters the region is known for produces high taste fruit, while the frost, fog and hail have also provided challenging conditions for growers. Mark and Robyn are the largest single organic growers in the country. Zespri is on track to sell around 3.9 million trays of New Zealand Zespri organic kiwifruit this season, which makes up around 3% of the total 119 million trays sold in 2015/16. Their production figures are: Organic: SunGold Green 16 hectares 2015 Production: 97,180 trays 110 hectares 2015 Production: 623,136 trays Conventional: SunGold 50 hectares 2015 Production: 86,378 trays Hayward 10 hectares 2015 Production: 31,651 trays Mark has been heavily involved in grower groups like New Zealand Kiwifruit Growers Association and industry committees. GENERAL SATURDAY Maungatautari Ecological Reserve http://www.maungatrust.org/ Maungatautari is an outstanding conservation initiative, surrounded by farmland, undertaken by forward-looking environmentalists, farmers and locals. It has seen 3363 hectares of native bush on a Waikato landmark, entirely fenced with a New Zealand designed pest-proof fence. 833 hectares of the area is privately owned or in Maori ownership. Within the enclosure are two smaller double-fenced areas, which has let the Trust running the venture, release endangered bird species and allow easy access for the public. These two smaller enclosures were completed by December 2004, with the full 47 km length fence around the entire area completed in 2006. The aim of the project is to remove for ever, or control, introduced mammalian pests and predators from the mountain and restore to the forest a healthy diversity of indigenous plants and animals not seen in our lifetime. Ten fulltime equivalent staff, and six contractors run the reserve with the help of 450 registered volunteers. Around 150 volunteers are active throughout the year. The work carried out by volunteers is valued at $350,000 year. The reserve is visited by 15,000 to 20,000 people a year, including 3000 children who come for educational programmes. A large number of endangered birds have been transferred to Maungatautari, including the North Island robin, North Island saddleback, stitchbirds, whiteheads, kiwi, yellow crowned parakeets, takahe, North Island kaka, Mahoenui giant weta, tuatara, and kokako. Some species have gone so well in this reserve that they have been able to relocate them to other areas in New Zealand. This includes takahe and kiwi. In order to reduce pests in the early days, aerial drops of 1080 (sodium monofluoroacetate) and two of an anticoagulant called Brodifacoum, were completed between 2003 and 2008. This was mainly to reduce possums and rats to levels where they could be managed using ground-baiting methods. All pest control since 2009 has been done using ground-based methods. Though possums, mustelids and rats are now largely excluded from the scenic reserve, mice still remain within the fence. These do not cause significant problems for our birds, but they may do in future for reptiles and invertebrates such as native snails and weta. Bill Garland: farming in harmony with the bush Rahiri Farm, translated means “to welcome”. It’s a 430Ha hill country property on the western slopes of Maungatautiri, directly south of Lake Karapiro. Altitude is 150 meters to 460 meters. 360 Ha is grazable land, 20 ha production forestry, and 40 ha native bush and natural wetlands. The farm runs 1950 breeding ewes, 350 replacement sheep and 400 - 450 mixed age cattle. Half the ewes are composite, or mixed breeds, and their progeny are used solely for meat production. Romney bred sheep make up the rest of the flock, these are mated to a composite sire, and ewe lambs are used as replacements for the composite flock. Romney ewe replacements are brought in from a flock that has been breed for tolerance to animal health problems, such as facial eczema and internal parasites. They dock 3000 - 3300 lambs from the 1950 ewes and ewe hoggets. All cattle are sourced from the dairy industry at 100 kg liveweight, and are slaughtered at two-years-of-age. Most of the meat is destined for the American grinder beef market. Approximately 90% of the 2600 - 2700 lambs finished for slaughter are sold to Wholefoods supermarket chain in America. The Garlands have to meet certain specifications for this market, seven months of the year. They have to meet stringent food safety standards, and the lambs are all grass fed. The conditions are that there are no antibiotics, GMO, and no hormones in the lifetime of the animal. Most of the 1500 kg of crossbred wool produced is sold to a local carpet manufacturer. Their goals are to farm the land as sustainably as possible, at the same time as making the most income posssible out of all classes of livestock and land. “We also strive to take care of the welfare of our animals, and maintain the farm in a way that makes it a pleasant place to work and share with others.” Their biggest input cost is fertiliser and lime. They apply up to 200 tonnes of fertiliser annually, using fixed wing aircraft, trucks and helicopters. The additional cost of using a helicopter can be justified where accuracy is important, and to avoid contamination of waterways and sensitive areas. Every year the Garlands budget a certain amount for environmental enhancement and restoration work. Over 25 ha of steeper land which should not have been developed, has been retired. 40 ha of native bush and wetlands, have been protected with perpetual covenants, registered on the title. About 25 km of fencing has been erected to protect these areas. The property is adjacent to the 3500 ha Maungatautiri restoration project. 8 km of the pest proof fence is on the property, and 25 ha of their private land is part of the restoration project. The farm features in New Zealand's National Museum, Te Papa, as an example of balancing commercial land use, with environmental sustainability. Maungatautiri and the surrounding districts have a rich Maori history, particularly during the period from the early 1800's through to the colonisation by European settlers. The property is regularly used for a range of activities, including education, promotion, recreation and field days. Bill has been involved in a number of off-farm activities, including regional and national farming politics, and been a board member of Q.E.2 National Trust, Waikato Conservation Board, Ballance Farm Environment Awards, and Animal Health Board. Ten years ago he received an ONZM for services to conservation and farming. Sue and Bill both grew up on farms in the Cambridge district, and started on their own accord as 20 and 21-year-olds. They are now close to 50 years on the property – the next challenge is where to from here. There is still probably 10 – 15 years of environmental work left to be done, and fixing the mistakes they claim they’ve made in getting to where they are. http://www.waikatoregion.govt.nz/Environment/Natural-resources/Biodiversity/Forestfragments/Forest-fragment-ca.