TO CREATE A CULTURE OF QUALITY

Response to the Forbes Insights-ASQ “Culture of Quality” Report

By Robin Lawton, October 16, 2014

The “Culture of Quality” report published in fall, 2014, by American Society for Quality

provides a snapshot of how surveyed leaders and quality professionals agree (or not) on

what a quality culture is, the degree to which they operate within one and what the key

drivers and practices are for achieving a strong and successful culture. One pervasive

finding was that there is disagreement between executive leaders of all kinds of

organizations who perceive their culture as more well-defined and better performing than

managers and those closest to actual quality management practices. In other words, the

view is rosier the higher you are on the leadership ladder.

On the other hand, there are two especially strong points of agreement across all surveyed

groups, irrespective of the respondent’s position. One is that customer expectations and

experience are the ultimate criteria for determining what quality is and the degree to which

the culture delivers it. The second is that respondents’ organizations could do a lot better in

uncovering and satisfying customer priorities.

These findings should not be news to anyone who has lead or is aspiring to achieve a strong

and sustainable quality culture. What could be particularly helpful is to highlight the

findings suggesting what actions can be taken to strengthen your culture, supported with

brief but sufficient depth to understand how to execute. My purpose here is to add some of

the specifics that can be very helpful for those of us with a strong bias for action.

Scattered throughout the report are several guidelines offered by interviewees that are

critically important but warrant expansion to be useful. Three of them rise to the top and

are strongly related to each other (report page numbers shown in parenthesis):

1. All employees must apply the four key elements of any strategy for building a

quality culture. (Page 8: Boeing’s Ken Shead).

2. Closely understand customer expectations so you can focus and give them what they

want. Study respondents overwhelmingly report low effectiveness by their

organizations in doing so. (Page 16: Intel’s Stan Miller and Rudy Hacker)

3. Develop a formal quality policy, common language and leader behaviors as

deployment mechanisms. (Pages 18-19, HP’s Rodney Donaville)

Four Elements of Strategy

Ken Shead says a culture of quality requires and ensures that all employees know:

Their product or deliverable

Their customer

Their customer’s quality expectations

How to measure that quality

These four elements look like simple common sense and, therefore, could mistakenly be

perceived as not particularly enlightening. It can be tempting for the reader to say to

themselves, “so what? I already know this”. Therein lies the problem for anyone wishing to

actually assure this is done. What is missing from the report is how to do this. It is not as

1

easy as it would first appear. We don’t know whether Ken offered details that didn’t make it

to the report. Let’s see how we can fill that gap.

Mr. Shead offers excellent guidance but the report does not make any reference to where

these four elements might have originated or where the mechanisms for implementing

them could be found. It turns out those four elements of strategy perfectly match the topics

in the first four chapters of my book written over twenty years ago, Creating a CustomerCentered Culture: Leadership in Quality, Innovation and Speed.1 The real-life questions

(stumbling blocks) the change leader and practitioner will encounter when seeking to

follow this simple strategy without the rest of the story include the following:

1. Is the employee to focus on “their product” at the enterprise, business unit,

functional group or personal level?

2. Is “their product” singular or are there many products an employee might have? If

there are many, how does one prioritize which are most important?

3. How does someone who does not create widgets such as Boeing’s airplanes, who

views their work in terms of service or knowledge (roughly 87% of the postindustrial workforce), define their product?

4. If the product could refer to something produced at one of four levels (suggested in

question #1 above), would “the customer” be the same party for each product?

5. Once we identify a specific product, are we to focus on the end-users for that

product, the brokers (who pass the product to others) or fixers (who modify or

correct the product for the benefit of end-users)? Does it matter if we don’t

differentiate them?

6. Are all end-users equally important?

7. Are customer expectations the same as requirements and needs? If not, is it

possible to meet all the agreed upon requirements but still end up with unhappy

customers?

8. When seeking to understand customer priorities, is it important to differentiate

expectations related to their subjective perception of the product, the product’s

objective performance, the process for acquiring and using the product or the

outcome produced by using the product? How would one do easily this?

9. Quality is often defined in terms of defects and deficiencies. If we eliminate things

gone wrong, is the result a strong quality culture?

10. How would one create quality metrics for squishy expectations customers may

insist upon such as easy to use, cool and innovative?

Concrete and easily applied answers to questions 1-4 are provided in Chapter 1 of the

referenced book. The other questions cannot not be successfully answered until that first

chapter is understood and applied. Chapter 2 answers questions 5 & 6, Chapter 3 answers

questions 7-9, Chapter 4 answers question 10. Now that you’ve got the key to the rest of

the story, we owe a big thanks to Mr. Shead for his succinct eloquence.

CLOSELY UNDERSTAND CUSTOMER EXPECTATIONS

We could refer to this topic as voice of the customer, customer experience or anything else

that represents a formal, organized approach for uncovering and satisfying what customers

want. The quality management field has a host of methods and tools that can assist, with a

sometimes dizzying degree of complexity and sophistication. The cure can be more difficult

1 An article providing a synopsis of that book can be found as item #4 at

http://www.imtc3.com/library/articles.cfm

2

to apply than it is to understand exactly what the problem is. Most culture leaders do not

have the time, patience, inclination or life expectancy sufficient to fully apply everything we

know. And even then, the vast majority of the literature and practice is aimed at enterprises

(and the 13% of post-industrial age employees personally engaged in) making widgets.

For the mere mortal leaders of quality and cultural transformation who include “the rest of

us”, there are two practical ways to begin taking significant action. Lucky for us, the first

way is to start with the answers to questions 1-8 in the section above. So now you’ve got

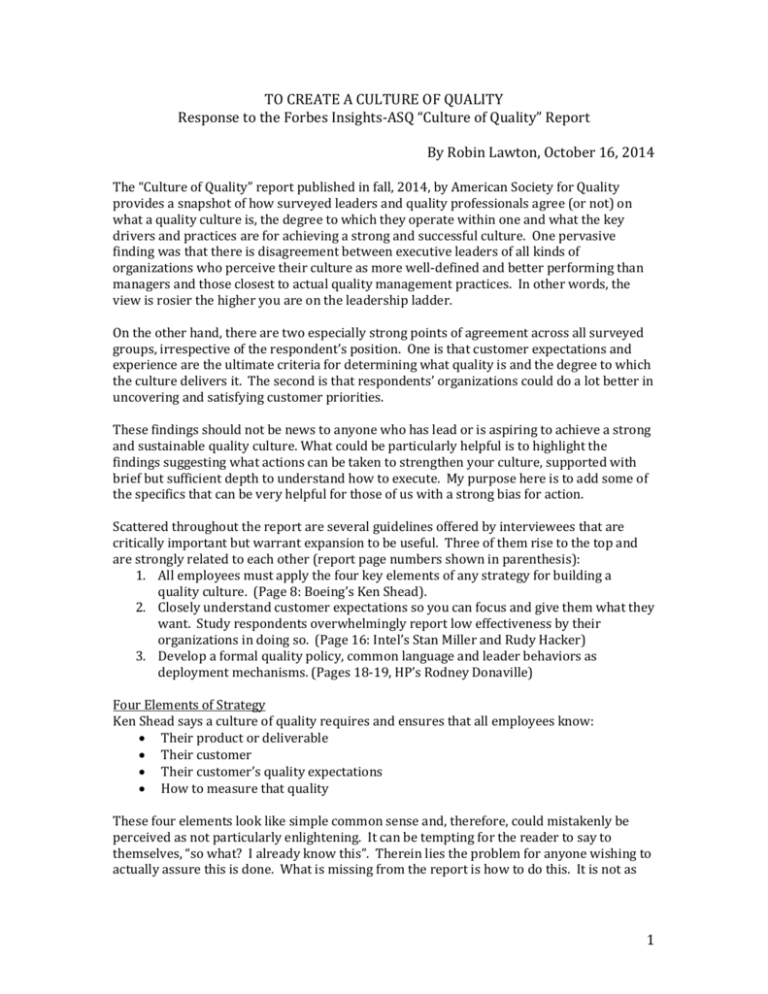

one roadmap. For those of us who like pictures, think in terms of relationships and

systems, like an easy reference that applies to every aspect of excellence and would like

everyone in the organization to have an unambiguous and shared view of the world, we

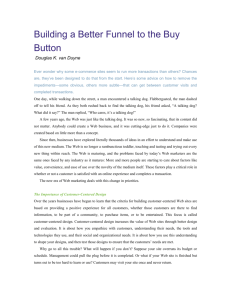

could use the graphic below.

Copyright © 2008 International Management Technologies, Inc.

All Rights Reserved. www .imtC3.com

8 DIMENSIONS of EXCELLENCE

CUSTOMER PRIORITIES

UNDESIRED

4

Product Acquisition

Process

Customers Want

PRODUCER PRIORITIES

PROCESS

C3DR-2

3

Product

Characteristics

Customers Want

P

R

O

D

U

C

T

Production Process

Producer Wants

Product

Characteristics

Producer Wants

8

7

2

Undesired

Outcomes

Customers

Want to

Avoid

DESIRED

1

Customer

Desired

Outcomes

OUTCOME

Undesired

Outcomes

Producer

Wants to

Avoid

6

Producer

Desired

Outcomes

5

Copyright © 2008 International Management Technologies, Inc. www.imtC3.com. All rights reserved.

EFFICIENCY

IDENTITY

PURPOSE

1

A culture of quality must address all eight topics labeled in this graphic. Traditional quality

management practices put especially heavy emphasis on Dimension 8. In fact, most

initiative names (lean, Six Sigma, activity-based costing, business process improvement,

etc.) explicitly work on improving processes. Mostly the producer’s processes. Dimension

4, the customer’ process for acquiring and using the product, generally gets far less

attention. Organization leaders wanting to truly be customer-centered work to beef up the

definition, measurement and improvement of Dimensions 1-4, in that order.

One way to test whether what we say we value is actually valued is to examine what gets

measured. Most healthcare organizations will admit that their customers (patients, in their

mind) want to achieve, above all else “good health”. This is the voice of the customer. Yet

the vast majority of healthcare providers has no written definition for good health (though

the World Health Organization has one), has no measure for it and no numerical goals for

improvement. There will be many measures for other things, mostly regarding operations

and compliance, but the most important customer outcome is not defined, measured or

linked to compensation or performance reviews (but volume, cycle time and cost are).

Customer surveys ask many questions (on courtesy, cleanliness, wait times) but none

regarding the good health outcome. We assume high scores indicate satisfaction, but we

have carefully chosen which questions to ask and which to avoid. The power of customers

is therefore diminished and staff behavior is not linked to what the strategic plan intends.

3

The 8 Dimensions of Excellence is described in practical detail in several articles written by

this author and published by Quality Progress/ASQ. Please see item #8 at

http://www.imtc3.com/library/articles.cfm , which also addresses the voice-of-thecustomer topic, especially relevant beyond the world of simply manufacturing. The article

intends to describe the steps a leader can take to “closely understand customer

expectations”.

QUALITY POLICY AND COMMON LANGUAGE

We have so far identified several terms that tend to be fraught with ambiguity, causing

chaos and confusion. As Rodney Donaville nicely states, establishing a common language

(absent ambiguity) is essential for the culture leader. Some of the terms that create the

greatest distress include the following, of which we have touched on several:

Product

Service

Customer

Expectations

Quality

Input

Output

Outcome

In providing answers to the ten questions in the first section above, we’ve indicated how to

create clarity, eliminate ambiguity and simplify the work of cultural leadership. We have

found there are five essential levers that a leader can push on to strengthen and change the

culture: language, values, measures, power and assumptions. The first three of these five

levers show up as topics in the Forbes Insights study. Just as the leaders interviewed in the

study did, we started here with language.

The moment we talk about a quality policy, we encounter another frequent stumbling block

on the road to a strong quality culture. All the executive interviewees in this study agree

that quality starts and ends with the customer’s definition of it. If that is true, are we after a

customer satisfaction policy or a quality policy? Is there any difference? The evidence

suggests there is a difference.

A traditional quality policy generally points us toward technical product or process

performance. In practice, it is common to find that quality policies encourage action to find

and reduce defects and errors. It is fair to say related tools and systems (root cause

analysis, corrective action, and so on) are more numerous and used more frequently than

design tools linked to customer priorities. That is, reaction is practiced more than

proaction. If it is possible to have a product with a very low defect rate but a high customer

defection rate, there is a difference between quality and satisfaction that matters. Likewise,

if we can have a product with a modest defect rate but fanatically loyal customers, there is a

difference between quality and satisfaction that matters.

Let’s solve the issue by putting the emphasis where all the leaders in the study say it should

go, on customer satisfaction. Now we get to examine what a satisfaction policy is. Consider

the following Customer Satisfaction Policy displayed prominently by a major retailer.

4

We guarantee customer satisfaction by refund, replacement or return.2

Does this policy address Dimensions 1 or 2? Since the intent is to describe the corrective

action the company will take when the customer is unhappy with a purchase, its focus is

Dimension 2 and is reactive. Compare that to the following Customer Satisfaction policy.

All employees, associates and partners will:

• Proactively solicit customer needs and expectations.

• Confirm that we have understood those expectations.

• Develop, package, deliver and support our products to meet those expectations.

• Measure the degree to which our customers’ product and outcome expectations are

achieved.

• Never blame the user when he or she cannot make a product or process work;

provide understanding then help. Assume they have done their best.

• Aggressively seek to close any gap between what our customers expect and what

they experience.3

Which of the 8 Dimensions of Excellence does this policy address? The first four bullets

emphasize behavior related to Dimension 1, the last two bullets cover Dimension 2. In this

case, there is also linkage to 8: how the producer will execute its intent to create satisfaction

(both proactively and in response to dissatisfaction).

A policy is a broad guide to action, often including an objective, a statement of intent and

principles. It is a basis for consistent conduct for those working within an organization. For

those external to the organization, policies help to understand what to expect from the

organization. In the second example above, the manner of deployment is spelled out

without getting into procedural details. The six policy elements are also constructed so that

measurement supporting accountability and verifying execution can be done.

SUMMARY

ASQ and Forbes Insights have provided us with great food for thought. It is probably fair to

say one purpose of the study was to identify some answers to “what are key culture of

quality practices?”, not necessarily “how can I advance my current culture and leadership

practices?” My purpose here has been to put some practical guidelines on the table for

those wanting to act on what the study has discovered and several interviewed leaders

allude to as keys to success. The report ends (page 33) by inviting readers to take a selfassessment to be available in a few months. But why wait?

A self-assessment already exists on this topic and has been completed by thousands of

leaders and quality professionals in all fields. It takes about six (6!) minutes to complete.

You get an instant score. More importantly, the questions themselves are designed in such a

way that, once you give your response, you’ll already have the start of an action plan

forming in your mind. Just select item #1 at http://www.imtc3.com/library/articles.cfm .

The average score across all responders is about 55 (out of a possible 105). Good luck.

Please let me know if the short action plan outlined here or the self-assessment has offered

2

Source: Labeled as Walmart’s customer satisfaction policy and displayed on the wall at the returns or customer

service desk.

3 Source: Developed by International Management Technologies, Inc. and provided to many of its clients with

permission to use.

5

useful insights, a practical path forward, a reason to celebrate or simply another cause for a

stiff drink.

ABOUT THE AUTHOR

Robin Lawton coined the term “customer-centered culture” in 1993 with his first book,

Creating a Customer-Centered Culture: Leadership in Quality, Innovation and Speed (5-star

ranked on Amazon). The methodology described there, now known as C3, has enabled

many organizations to achieve business growth and market leadership, savings per project

of as much as $20 million, 90 percent reduction in time-to-market, phenomenal customer

experience, Baldrige National Awards and other notable results.

Rob has been ranked #1 of 88 international business speakers and been a keynote speaker

sponsored by professional societies such as Japan Management Association, Association for

Manufacturing Excellence, American Marketing Association, American Society for Quality,

Federal Executive Board and many others. He inspires, challenges and equips those driving

excellence to do what they never thought possible.

Mr. Lawton founded International Management Technologies, Inc. in 1985. His firm’s

mission is to help organizations create rapid strategic alignment between enterprise

objectives and customer priorities. His principles, strategies and tools are outlined in his

books and articles at http://www.imtc3.com/library/articles.cfm .

Rob is listed in Who’s Who in Business Leaders, named Quality Guru by American Society

for Quality and won other prestigious recognition. His ideas have appeared in many books,

including the following:

Beyond Strategic Vision, Effective Corporate Action with Hoshin Planning, M. Cowley, E.

Domb

The Lean Extended Enterprise: Moving Beyond the Four Walls to Value Stream Excellence,

T. Burton

The Kaizen Blitz: Accelerating Breakthroughs in Productivity and Performance, A. Laraia

The Performance Improvement Toolkit: The Guide to Knowledge Based Improvement, R.

Gerst

ISO 9001:2000 Quality Management System Design, J. Schlickman

Tools to Create Great Corporate Strategies Using Insights from History and Science, Dudik &

Dudik

We Don’t Make Widgets, Ken Miller

Leadership Helping Others To Succeed, Warren Bennis, Rep. Pat Schroeder, Sen. George

Mitchell, Robin Lawton, et. al. (2014)

Please contact Rob at:

Robin.lawton@icloud.com

www.imtc3.com

941-704-9888

6