310715100431tehjaICTpaper

advertisement

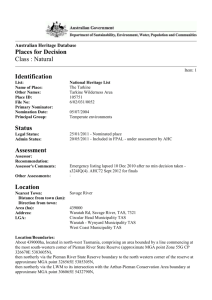

SusChemE 2015 International Conference on Sustainable Chemistry & Engineering October 8-9, 2015, Hotel Lalit, Mumbai Removal of Zr (IV) from Used Pickling Solution by Solvent Extraction D.S.R.Theja1, Tessy Vincent2, S.SaiRam1, P.S.Dhami2, Poonam Jagasia2, J.N.Sharma2 Gourahari Das1, Meena Ravindran1 1 Nuclear Fuel Complex, Nuclear Fuel Complex, Hyderabad Nuclear Recycle Group, Bhabha Atomic Research Centre, Mumbai E-mail addresses: theja@nfc.gov.in, tessyv@barc.gov.in, sairam@nfc.gov.in 2 1. Introduction: Pickling is an important step during fabrication of various Zircaloy products. It removes the oxide layer & surface contaminants by dissolving in HF & HNO3. Over a period of use, pickling solution gets depleted in HF and enriched with salts of Zr and other alloying elements and is discarded as used pickling solution (UPS) when the Zr concentration exceeds 35 g/l. UPS is a valuable reagent which needs to be recycled for making the process environmental friendly. Extraction studies were taken up to remove the Zr from UPS Literature available on extraction of Zr from UPS is very limited [1-3]. Various extractants were tried for preliminary solvent extraction studies and the detailed study carried out with the chosen ligand is discussed. 2. Material and Methods: Ligands like Tetra ethyl hexyl di-glycol amide (TEHDGA), Carbamoyl methyl phosphine oxide (CMPO) and Mono glycol amide (MGA) used in the present study were available from Process Development Division, BARC, Mumbai. Analytical grade HNO3, HF and oxalic acid were purchased from Ms. S.d.Fine-Chem Ltd, Mumbai. Zr concentration in the feed as well as in the raffinate was analyzed using Inductively Coupled Plasma-Atomic Emission Spectroscopy (ICP-AES). 3. Significant Results and Discussion: Experiments were carried out for the UPS containing 35.5 g/l of Zr with TEHDGA, MGA and CMPO using 30% Iso-Dodecyl Alcohol (IDA) as a phase modifier and 70% dodecane as diluent with an organic to aqueous (O/A) ratio of 3. Highest extraction of 42% was found with 0.2 M MGA with a low distribution ratio (D Zr) of 0.24 as seen from table-1. With an aim to improve DZr, one more run was performed with 1M MGA which resulted in a DZr,of 1.46 with 78.43% extraction. Stripping experiment was also carried out using 0.2 M oxalic acid and 0.5 M HNO3 for the loaded organic containing 10g/l of Zr with an O/A ratio of 1. In two contacts, 80% separation was obtained. Table 1: Comparison of Extraction Performance with Various Extractants Sr. No. 1 Ligand (0.2M) Raffinate conc. g/l TEHDGA 31.10 Distribution Ratio (DZr) 0.05 % Extraction 2 3 CMPO MGA 0.12 0.24 26.6 42 25.57 20.05 13.1 As the UPS contains about 4.2 M HNO3, experiments were carried out to study the uptake of nitric acid with 1 M MGA by varying the concentrations of HNO3 in the range 0.5- 6.0M for an O/A ratio 1. Free acidity in both the phases was calculated by titration method. Acid uptake equilibrium is depicted in Fig.1. It can be seen that the free acidity increases as the nitric acid concentration increases. Further experiments have been performed in cross current mode to study the efficiency of 1M MGA for the complete removal of Zr from UPS by maintaining an O/A ratio of 3 and the results are summarized in table-2. Stripping behavior has also been studied for loaded organic in three contacts using 0.2M oxalic acid and 0.5 M HNO3. In three contacts 99.8% Zr could be transferred to aqueous phase. 1 SusChemE 2015 International Conference on Sustainable Chemistry & Engineering October 8-9, 2015, Hotel Lalit, Mumbai 0.30 Free acidity M (Organic phase) 0.25 0.20 0.15 0.10 0.05 0.00 0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0 5.5 6.0 6.5 Free Acidity M (Aqueous) Figure 1. Acid Uptake by MGA Table 2: Extraction Performance with IM MGA in cross current mode Contacts C1 Zr in feed, g/l Zr in aq. 35 3.7 C2 C3 C4 3.7 0.9 0.23 g/l 0.9 0.22 0.05 Zr in org. g/l DZr 10.43 2.81 %Extraction 89.52 0.93 0.23 0.057 97.45 99.38 99.84 1.03 1.03 1.04 Conclusion: The synthesized MGA is found to be a suitable ligand for the extraction of Zr from UPS and quantitative stripping of the loaded Zr in MGA is also feasible by 0.2 M Oxalic acid and 0.5 M HNO3. References [1] Airy P. Lamaze, Process for recovering acids& zirconium contained in pickling solutions, U.S Patent: 4200612 filed on Nov, 7, 1978 [2] J. Rynasiewicz, Zircaloy pickle bath salts- chemical nature & thermal decomposition of a hydrated zirconium fluoride, J. Nucl. Materials, 12 (2) 1964, 153-158 [3] Bang . M. Kim,, Process for recovery of zirconium from acid spent etching solutions. U.S Patent: 4572824 filed on Nov, 1, 1984 2