Fire Safety Self Inspection Worksheet for

advertisement

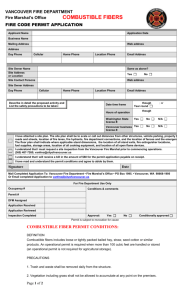

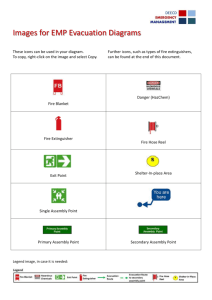

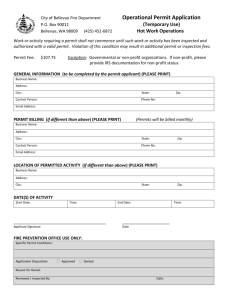

City of Galesburg Operating Under Council – Manager Government Since 1957 Galesburg Fire Department Fire Prevention Bureau 150 South Broad St. Galesburg, Illinois 61401 Office: 309-345-3756 Fax: 309-343-1340 Email: Fireinsp2@ci.galesburg.il.us You may complete this form on your computer by going to www.ci.galesburg.il.us , click on “Documents and Forms” under the “Quicklink” heading. In the search box enter: inspection. The Self-Inspection Worksheet icon will appear in the list. Open the document, save it to your computer, fill in the blanks, and save it. You may e-mail it to us as an attachment to: Fireinsp2@ci.galesburg.il.us. If you complete this form in hard copy, return it by fax to 309-342-1340 or mail it to Galesburg Fire Department, at the address shown to the left. SELF-INSPECTION WORKSHEET FOR BUSINESSES Business Name: Date of Inspection: Address: Phone : Person Conducting Inspection: Phone : Position: Building Exterior Y N N/A Email: List includes most common safety concerns. All code references are from the International Fire Code 2006 freely viewable at www. iccsafe.org . Additional information on city website. 1. Are all sides of the building free from combustible weeds / debris or storage? 304.1 2. Are address numbers posted a minimum 3- inch, contrasting color, visible from street, adjacent to principle entrance and plainly visible. 505.1 & GMC 97.002 3. Buildings with fire sprinklers/standpipes: Do you have a 3-foot clearance around fire department connections and are caps in place? 912.3 Means of Egress 4. Are all exit signs operational and illuminated? (press test button) 1027.3 5. Are all emergency lights operational? (press test button) 1027.5 6. Are all exit doors and points of egress free of obstructions? 1028.3 7. Manually operated flush bolts or surface bolts eliminated? 1003.3.1.8.1 8. Are stairwell and all other fire doors closed? 703.2 9. Are outdoor fire escapes maintained? 1027.16.7 Storage and General Housekeeping 10. Is all storage neat and orderly? 315.2 Page 1 of 5 Y N N/A 11. Are combustibles stored away from heat source such as a furnace, stove, water heater, electric motors and other heat sources? 315.2 12. Is storage less than 12 feet in height; 18 inches below sprinkler heads; and a minimum of 2 feet below ceiling? 315.2.1 13. Have combustibles been removed from boiler room, mechanical room and electrical rooms? 315.2.3 14. Are compressed gas cylinders secured from falling? 3003.5.3 15. No flammable liquids in basement and have permit if >5 gallons? (10 gallons or more must be stored in approved closed metal cabinet) 105.6.16, 3404.3.4.4 & 3404.3.5.1 16. Fueled equipment not stored or operated inside (exceptions: service stations & fire sprinkled buildings in approved locations with < 10 gallons). 313.1 17. Garbage cans > 40 gallons stored inside must be non-combustible with lids. 304.3.2 Electrical 18. Exposed electric wires, defective electric equipment, modified or damaged equipment are not present. There are no open junction boxes or open-wiring splices. 605.1 and 605.6 19. Is there 30-inch clearance in front of electrical panels? 605.3 20. Are all electric room doors and electric panels labeled to identify what they control? 605.3.1 21. Extension cords are in good condition and used only with portable appliances and not extended through walls, ceilings, floors, or under rugs and plugged directly to an outlet. 605.5 22. Power strips are fused, UL listed, and plugged directly into outlets. No multi-plug adaptors. 605.4 23. Are all portable electric space heaters UL Listed, plugged directly to an outlet and a 3 foot clearance maintained from combustibles? 605.10 Building Fire Protection 24. Have all breaches, missing ceiling tile/holes/pipe chase in the wall or ceiling that could allow fire into the hidden spaces been repaired or replaced? 703.1 25. Minimum 2A fire extinguisher mounted and visible with gauge in green and inspection tag < 1 year old, within 75 ft. walking distance to all areas of building? 906.1 26. Does the kitchen hood fire suppression system have an inspection tag < 6 months old? 904.11.6.4 27. Are the hood and duct maintained in clean condition? 904.11.6.3 28. Does the sprinkler system gauge read > 30 PSI? 901.4.4 Page 2 of 5 29. Is the fire alarm power light on with no alarm or trouble indicators on the panel? 901.4.4 Y N N/A 30. Are the zones and/or detector locations of your fire alarm clearly labeled, diagrammed, or digital readout so an activated detector can be quickly identified? 901.4 31. Do you have documentation of “Fire Safety Plan”& “Fire Evacuation Plan” and fire drills (requirement varies by building use and size). 405 & 406 32. Do you have all necessary operational fire permits (some listed below)? 105.1.1 33. Smoking allowed in approved areas only. 308.2.1 Note: Documentation required for annual tests of sprinklers, standpipes, fire alarms, and rolling/sliding fire doors is handled under our FPSR tracking and can be forwarded to fireinsp2@ci.galesburg.il.us Checklists Permit Specific Assembly Permit (“Assembly” = > 49 occupant load): Y N N/A 1A. At least 2 exits out of assembly with exits signs and emergency lighting.. 1019.1, 4M. Combustible weeds / debris 10 ft from fuel handling equipment. 2205.7 5M. Warnings on signs visible to each dispenser (“No smoking”, etc.) 2205. 1011.1 & 1006. Lumber Yard Permit 2A. Do doors from assembly swing in direction of exit? 1008.1.2 Y 3A. Do doors with magnetic holdopen devices release with alarm and close completely? 703.2. 4A. No latch on exit door other than panic hardware. 1008.1.9 N N/A 1L. Fire Truck access to all sides of storage (20 ft wide 13 ft ht) 1903.6 2L. Lumber secured by minimum 6 ft fence. 1909.4 3L. Sawdust control system effective with proper grounding and bonding. 1903 5A. Exit passageways min. 44 inches. 1021.2 4L. Fire extinguisher within 50 ft of saw. 1904.2 6A. Is the occupant load posted? (required if entertainment venue) 1004.3 5L. Systematic cleaning of entire area affected by sawdust. 1903.3.1 Motor Fuel Dispensing Permit 6L. Fire sprinklers required in woodworking areas > 2500 sq ft (excluding storage) established after 7/15/2002. 903.2.3.1 1M. Emergency fuel disconnect required 20-100 ft of dispenser – marked and visible. 2203.2 Repair Garage Permit 2M. Dispensing devices are in clear view of attendant. 2204.2.4 1R. Machine used to clean parts is listed. 2211.2.1 3M. Fire extinguisher within 75 ft of all dispensers. 2205.5 2R. Oily waste placed in self-closing metal cans. Page 3 of 5 3R. Spray finishing only if have permit or paint is non-combustible. 2211.2. 2211.2.3.2 4LP. Containers stored so relief valve up in vapor space. 3809.3 4R. Ignition sources located >18 inches above the floor. 2211. 5LP. Containers secured from tampering and vehicles. 3809.13 5R. Pits/basements are ventilated. 2211.4.3 Flammable Finish Application Permit 6R. Used motor oil containers must have spill protection if > 55 gallon containers or > 1,000 gallon aggregate. 2211.2.2.1 Hot Works Permit (welding): Y N N/A 1H. Person designated to ensure hot works safety and maintenance of records of “pre-work check” reports. 2603.5 Y N N/A 1F. Spraying of flammable or combustible finishes done in spray room meeting the International Building Code or a spray booth NFPA 33 listed, both with automatic fire extinguishing systems; or limited to 9 sq ft surface area. 1504 2F. 3 ft clearance around spray booths. 1504.3.2.5 2H. Is area of cutting and welding restricted? 2601.3 3F. Fire Extinguisher minimum 4A40B within 30 ft. of finishing area. 1504.4.1 3H. Fire extinguisher minimum 2A:20BC within 30 ft even when work is off location? 2604.2.6 4F. Protect fire sprinkler heads with approved lightweight bags and replace if heavily coated. 1504.5.2 LP Storage / Refill Station Permit 5F. Safe distances maintained from open flames, sparks, hot surfaces, smoking areas, non-explosion proof wiring. 1503 1LP. Containers not stored on roofs, in basement or pit. 3809.6/ 2LP. Storage kept 10 ft from building openings (5 ft if 2 exits), LP dispensing stations, and combustible materials; and 20 ft from gasoline dispensers. 3809. 12 6F. Ventilation working in vapor areas. 1504.7 3LP. Mounted fire extinguisher minimum 40BC within 30 ft of storage. 3808. 2 If you answered “no” to any question, please correct the violation before returning this form or add a comment as to your plans to correct. Item # Comments Page 4 of 5 Signature of Person Conducting Inspection: ___________________________________ Page 5 of 5