Pita & Chapatti Semi Automatic

advertisement

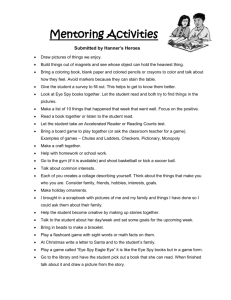

Semi-automatic line for pita and thin Armenian lavash production with the capacity up to 500-600 pcs/h Pita is a traditiomnal unleavened arabic bread. It is a flatbread distinctive characteristic of which is the presence of pocket inside. The pocket could be opened by cutting the edge of pita with a sharp knife for filling it with salad and meet. Dough dividing for 2 layers is caused by water steam influence which is formed in dough when baking pita and which is accumulated in bubble in the middle of the flatbread, separating the layers of dough thus. Just due to this characteristic pita is in demand in home cooking as well as in fast-food retail chains. Exclusive Dealer in: Africa, Middle East and American Continent http://www.Tradeway.us Tel: 1-661-263-1482 Valencia, California USA E mail: vartanv@Tradeway.us PRODUCTION PROCESS Complete set of the line: 1. Flour sifter 2. Water batcher with heating 3. Dough kneading machine 4. Dough dividing machine with roller 5. Trays for preliminary proof 6. Rolling machine 7. Conveyor for proof 8. Tunnel oven 9. Cooling conveyor 10. Stabilization table 11. Table for packaging For European Union and other European countries our products meet all European Standards and have CE Euro-certificate. For North American Market we provide certifications and Electrical converters Specifications exceeds International Food Safety Standards Description of the line’s operation Dough prepared in the dough preparing section 1, 2, 3 is fed to a dough dividing machine 4 which produces dough pieces of the required weight. Dough pieces are put in the wooden trays 5 in which they pass the preliminary proof. Trays are designed in such way so that in the process of putting of dough pieces on each other a closed chamber with its own microclimate required for the proof is formed. After the proof dough pieces are being made flat and round with the help of rolling machine 6. After that dough pieces are put on the belt of the conveyor for main proof 7 where they pass proof before the feeding to the hearth of the electric tunnel oven. From the output conveyor of the proof chamber dough pieces are directly fed to the hearth of the tunnel oven 8. After the baking pita is cooled on the cooling conveyor from where baked pita pieces are taken, put together in the piles and passed for the packaging by operator. Tunnel oven has a system of oven’s speed control for choosing the most optimal baking time as well as heating zones control system for creation of the most optimal temperature mode. Specifications № Name Unit of measure Parameter 1. Capacity pcs/h 500-600 2. Voltage V 3x380 3. Installed capacity kW 80 4. Power consumption kW 60 5. Baking time sec 60-90 6 Thickness of pita mm 1-3 7. Diameter of pita mm 100-250 8. Weight of pita g 50-200 Semi Automatic pita production line with the capacity of 500-600 pcs/h below: № Name of equipment Quant., Price, USD pcs. Complete set of the line for pita production, including: 1 Flour sifter 1 2 Water batcher with heating 1 3 Dough kneading machine 1 4 Dough dividing machine with roller 1 5 Stainless steel trolley 4 6 Trays for preliminary proof 104 7 Rolling machine 1 8 Conveyor for proof 1 9 Tunnel oven 1 10 Cooling conveyor 1 Total cost of the equipment*: 3500 3500 5000 7480 1 800 2600 4800 13800 25200 3700 $ 85, 537.