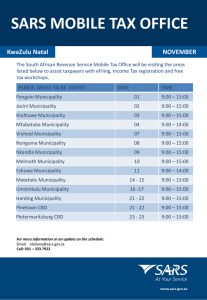

Appendices - 366Kb ~ 2 min - South African Waste Information Centre

advertisement