Horticulture Hazard Checklist: Hazardous Chemicals

advertisement

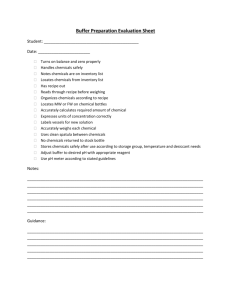

Page |1 Operational Manual Horticulture Hazard Checklist – Hazardous Chemicals Owner/ Manager: Property name and address: Contact: Completed by: Storage ACT NOW ACT ASAP OK PLAN/CONTROL Is there an inventory for all types of chemical and pesticides stored on the farm? Are Material Safety Data Sheets (MSDSs) and labels available for all agricultural and veterinary chemicals used and stored on the farm? All chemicals stored in their original containers and with clear and legible labels? Are all chemicals stored in a properly constructed and lockable area, which is resistant to fire and prevents access by children and other unauthorised persons? Are there clear warning signs posted on outside of storage area? Is the chemical store properly ventilated? Is there sufficient light in the chemical stor so chemicals can be identified and their labels easily read? Are incompatible materials stored away from each other? Do chemical storage locations have an area to retain accidental spills? Is the storage adequate for volumes of chemical held in the store? Are materials available to control spills in the storage area, eg sand? Do amounts of certain chemicals held on the farm require a Dangerous Goods License? Are chemicals protected from moisture? Disclaimer: This document does not, in any way, excuse a person from doing all that is reasonable to ensure the health & safety of themselves & others. It is necessary to check with the relevant state or territory work health & safety authority for appropriate information. Funded by NT Government Department of Business Page |2 Are chemical stored according to label instructions and MSDS? Disclaimer: This document does not, in any way, excuse a person from doing all that is reasonable to ensure the health & safety of themselves & others. It is necessary to check with the relevant state or territory work health & safety authority for appropriate information. Funded by NT Government Department of Business Page |3 Are fire extinguishers located adjacent to fuel & chemical storage areas? Is the recommended PPE for chemical available? Is there an emergency shower and eye wash located adjacent to the chemical mixing/storage? Transport ACT NOW ACT ASAP OK PLAN/CONTROL ACT NOW ACT ASAP OK PLAN/CONTROL Are chemicals containers checked for leaks or damage before transport? Are chemical transported in a compartment separated from people and foodstuffs? Are chemical containers well secured during transport? Are vehicles with chemicals locked when parked to prevent access by unauthorised persons? Are chemical protected from weather during transport? Is there documented emergency response procedure in the event of chemical spills and during transport? Mixing/ Loading/Cleaning Down Is there good ventilation at the mixing site? Is appropriate PPE available at the mixing site? IS the PPE in good condition? Do all operators use PPE during mixing/ loading according to label requirement? Are there good washing facilities and an emergency shower located adjacent to the mixing/ loading area? Are mixing tanks free from leaks or risk of splashes during mixing/ loading? Are the following systems used for mixing and loading? Manual Pouring/ Mixing? Does the system pose risk of exposure due to awkward system, e.g. pouring into spray tank above head height? Pump/bung/ tap fitted on drum? Does the system pose risk of exposure due to leakage fittings? Closed system transfer? Does the system pose risk of exposure from leaking fittings or hoses? Other, E.g. powders, granules? Does the system pose risk of exposure to dust or powders? Disclaimer: This document does not, in any way, excuse a person from doing all that is reasonable to ensure the health & safety of themselves & others. It is necessary to check with the relevant state or territory work health & safety authority for appropriate information. Funded by NT Government Department of Business Page |4 Crop Spray Application and Reentry systems Is appropriate PPE used by spray operators? Is the PPE in good condition? ACT NOW ACT ASAP OK PLAN/CONTROL ACT NOW ACT ASAP OK PLAN/CONTROL List the type of spray equipment used 1. 2. 3. 4. 5. Are cabined tractors/ vehicles used? If yes, in cabin air filtered to remove chemicals? Are spray lines, taps and nozzles checked and maintained before spraying? Is clean water carried for washing? Are clean gloves carried for emergency use? Policy and Practice Are chemicals selected on their efficacy to pests and safety to workers? Are all pesticides used according to their labeled safe use? Have all workers received safety induction for chemicals used on this farm? Have all workers who use chemical trained in their safe use? Are people not involved in the spraying operation kept away? Do all operators use PPE during spraying according to label requirements? When chemicals are transported on public roads, are they transported in accordance with the Dangerous Goods Legislation? Are people not involved in the mixing/ loading operation kept away from the site? Is all mixing and preparation of farms chemicals preformed at a designated site? Is all equipment used during mixing/ loading cleaned down after use? Is spray equipment checked and maintained before starting to reduce need for in-field adjustment? Disclaimer: This document does not, in any way, excuse a person from doing all that is reasonable to ensure the health & safety of themselves & others. It is necessary to check with the relevant state or territory work health & safety authority for appropriate information. Funded by NT Government Department of Business Page |5 Do operators wash hands after spraying and before eating, drinking and smoking? Have there been any leaks, spills or splashes causing exposure during spraying? If yes, what action is needed to reduce this risk? Are there rules preventing all people from entering a sprayed crop area before the expiry of the re-entry period? If workers, agronomists are required to enter sprayed crop before expiry of the re-entry period, is suitable PPE provided and used? Is all equipment cleaned before it is services or sent for repair? Are containers triple rinsed and disposed of in accordance with relevant authorities procedures? Are AVCARE or othe relvant procedures followed in dispoing of chemical containers and excess chemical? Do operators wash their hands after mixing, loading and before eating, drinking or smoking? Are there documented and known emergency response procedures in the event of a chemical spills and exposure during mixing/ loading Have there been any leaks, spills or splashes causing exposure when mixing, loading or cleaning down? If yes what actioned is needed to reduce this risk? Is an inventory maintained of all chemicals stored on the farm? Are there documented and known emergency response procedures in the event of a chemical accident? Disclaimer: This document does not, in any way, excuse a person from doing all that is reasonable to ensure the health & safety of themselves & others. It is necessary to check with the relevant state or territory work health & safety authority for appropriate information. Funded by NT Government Department of Business Page |6 Disclaimer: This document does not, in any way, excuse a person from doing all that is reasonable to ensure the health & safety of themselves & others. It is necessary to check with the relevant state or territory work health & safety authority for appropriate information. Funded by NT Government Department of Business