Lime producing and usage possibilities

advertisement

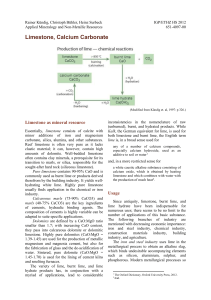

Construction Trainers Training – CT Train PRODUCING AND USING THE LOCAL LIMESTONE LIME PRODUCTS IN TRADITIONAL WAY in Saaremaa, Estonia in company Limex AS. About the company LIMEX AS For centuries already the world of construction has known a material burned from limestonelime. It has been more than a hundred years since lime has been burned in the major Estonian island-Saaremaa (Ösel). Limex Ltd., a private capital based limited company, which was established in 1994, renovated an old limekiln and started to burn lime there using a centuriesold technology, which has practically not changed and ensured the production of quality lime for more than 50 years. The peculiarity of the technology and a guarantee of high quality is manual work, which begins from the selecting of limestone to be burned and ends with the sorting of the finished produce into different quality grades. Only well-dried wood is used for burning, which does not produce additives lowering the quality. The planned annual is up to 500 MT of high-quality lime in the form of paste (approx. 50% water), which is preserved in underground storage, where the lime also rips further. Lime has been used as a building material for very long, however, especially intensively since 15th-16th century, and in Europe the main construction material used in Hanseatic towns has also been lime. We believe that lime is the most suitable material for plastering and painting of historic buildings and facilities without hydro isolation, as lime lets the water vapour to pass through. Lime is also used in new buildings because if plasters and paints contain natural lime, the wall can “breathe” freely and humidity can travel around without causing serious consequences on the finished surface. Here the following rule should be followed: whitewash on coat of plaster and cement whitewash on lime cement plaster. Whitewash can also treated with natural pigments. Today it is also important that lime is a natural construction material and is environment- and consumer-friendly. Currently Limex Ltd distributes its produce under registered trademark LIMEX SAAREMAA LUBI® (SAAREMAA LIME) Pictures: http://www.limex.ee/pildigalerii/?album=1&gallery=1 This project has been funded with support from the European Commission. This publication [communication] reflects the views only of the author, and the Commission cannot be held responsible for any use which may be made of the information contained therein. Material is based on information from webpage www.limex.ee and on information gained from workshop in Lubjapark on 30.06.2014. For more information about lime, contact Mr Priit Penu limex@limex.ee Construction Trainers Training – CT Train PRODUCTION PROCESS 1. ABOUT LIMESTONE The local limestone dates back more than 400 million years, to the warm and tropical climate that prevailed during the Silurian period; at that time, the island of Saaremaa shared the same latitude as what is now Australia. Therefore, our limestone has travelled across the equator and reached the northern hemisphere. Not all layers are suitable for manufacturing lime and the raw materials requires proper sorting to give high-quality lime. 2. EXTRACTION OF LIMESTONE. The first stage of lime production involves the extraction or mining of limestone from quarries or mines. The process starts with the removal of soil from limestone, followed by breaking limestone into smaller lumps. Wedges, crowbars and stone hammers are used for cracking the limestone. Early spring is the best time for limestone extraction – the stress caused by cold is still present in limestone strata and this makes the breaking and extraction process easier. Broken pieces of limestone are with 20-30cm diameter and different shape, which are transported by tractor to the lime kiln. Since different layers of limestone have different quality during the rock breaking also the visual selection of quality rock will take place. Visual distinction is mainly based on the layer´s color, the principle of which is as follows: the darker (browner) is limestone, the better the quality. In one time there are three different limestone layers are in mining operation, marl which the intermediate layer (10-15cm) discarded by visual inspection. From the top, approximately 40cm layer of wallboard produced less good plaster and grout lime and less demanding (eg. Agricultural purposes), limewash. Lower, higher quality layer (thickness ca 1m) will be allocated, in turn, is made up limewash. In one instance of a mining complex the thickness is around 1.5m. The pavement thickness is 1020cm which were removed from the area trenched and stored for later re-cultivation using the edge of a career. This project has been funded with support from the European Commission. This publication [communication] reflects the views only of the author, and the Commission cannot be held responsible for any use which may be made of the information contained therein. Material is based on information from webpage www.limex.ee and on information gained from workshop in Lubjapark on 30.06.2014. For more information about lime, contact Mr Priit Penu limex@limex.ee Construction Trainers Training – CT Train 3. LIME KILN Usually two separated chambers can be found inside the kiln – a burning chamber and a stone chamber. The burning chamber or furnace is the place where firewood is fed during the burning process. It is separated from the stone chamber by sidewalls made of limestone and on top by an arch built of large pieces of limestone, therefore, the stone chamber is placed on top and along the sides of the burning chamber. After limestone is crushed the kiln is prepared for the burning process. First of all, square Inside of lime kiln stone stones of equal size, as smooth as possible, have to be collected to chamber 1 build the wall and burning chamber that will be later used to burn the wood. The burning chamber will be made of limestone, extracted from special layer (so called burning chamber layer), the lumps begin as flat and rectangular as possible. The burning chamber occupies approximately 2/3 of the width of the kiln and its height, depending on the size of kiln is approximately 80-150 cm. Smaller and bigger openings are left in the walls of the burning chambers for a draft, which ensures a high-quality lime burning process (in the despite kiln, the openings can be seen in rear wall of the kiln). This kiln allows worker to observe the burning chamber, which is built without using vault stones.Today the limestone is burned in kiln which is Cross section of lime kiln: A-burning 3,8 m in height and 1,5m in width. chamber, B-stone chamber Drawing of V.Reiter 1983 This project has been funded with support from the European Commission. This publication [communication] reflects the views only of the author, and the Commission cannot be held responsible for any use which may be made of the information contained therein. Material is based on information from webpage www.limex.ee and on information gained from workshop in Lubjapark on 30.06.2014. For more information about lime, contact Mr Priit Penu limex@limex.ee Construction Trainers Training – CT Train 4. BURNING PROCESS. Lime in burning process 1m3 of well dried tree per 1 hour 1 The heating of the lime kiln usually takes 50 to 75 hours depending on weather conditions, raw material and heating material. (The heating of AS Limex lime kiln usually begins early Wednesday morning and finishes late on Friday night. The kiln allowed to cool on Saturday and Sunday and then emptied on Monday. The capacity of lime kiln is around 27-28 tons of limestone lumps, which are piled on top and along the sides of the burning chamber in irregular way to leave enough space between the lumps-such a pattern ensures a good, constant draught inside the kiln and, therefore, uniform `completion` of the stones. The kiln had to remain burning all time and every hour, approximately 1m3 of well dried, 2m pieces of firewood were added to kiln. The heating material is drying next to the kiln and for forest tree it takes about 2 years. The firemen are working in 8 hours shifts. The temperature inside the kiln remains between 1000-1300 degrees Celsius. During the burning process CO2 is emitted and the following formula can be used to describe the process. CaCO3==>CaO+CO2^ CaCO3 – Limestone, CaO - Quicklime The surface of well-burnt limestone acquires a greenish-yellowish tinge and it will lose about 30% of its weight; however, the shape of lumps does not change. The volume of burnt limestone inside the kiln somewhat decreases and this will result in decreased burning intensity inside the kiln, which is one of the indicators to show that the burning process is about to end. Burnt limestone or quicklime is a product that is characterised by extremely high chemical activity and, when in contact in water, it will immediately start to hydrate and will rapidly become a powder or a paste. As already mentioned above the stone need to calm down about 2-3 days before extracting from the kiln. Burnt limestone is extracted from the kiln using special crate that is filled manually and lifted out of the kiln by a crane, loaded onto a truck and then delivered to the hydration site. This project has been funded with support from the European Commission. This publication [communication] reflects the views only of the author, and the Commission cannot be held responsible for any use which may be made of the information contained therein. Material is based on information from webpage www.limex.ee and on information gained from workshop in Lubjapark on 30.06.2014. For more information about lime, contact Mr Priit Penu limex@limex.ee Construction Trainers Training – CT Train 5. HYDRATING/ SLAKING THE LIME. To hydrate lime, quicklime (burnt limestone) and water are mixed, followed by a chemical reaction, described by following formula: CaO+H2O ==> Ca (OH)2 The chemical compound obtained is called calcium hydroxide or slake/hydrated lime. Lime is hydrated in special bath tube, which situated approximately 2km from kilns. The measurements of bath tube is 2*3*0,5 m and it this is filled with 200-300 kg of quicklime and about 2,5 tons of water, followed by 15-20 minute reaction or hydration. The solution will then mixed to allow maximum contact between the burnt stone and water. As a result of the reaction, the burnt limestone will „melt“ or decompose and dissolve in water, and we obtain white, liquid „lime cream“, which is then sieved and charged into pits in the ground, also known as lime pits. In pits like that, excess water will be drained into soil in a couple of days or a week and then there is left with a mass resembling toothpaste, containing about 50% water. Ex post hydration and maturing of lime takes place in these pits; this may anywhere from 3 months to dozen years. The longer the time is allowed to mature, the smaller the lime particles are and the quality of lime improves. Lime pasta/ Lime putty is used mainly on construction sites as component in mortars and plasters, for producing lime wash or for liming acid soil. manager of lime company Mr Priit Penu shows the lime putty in lime pit Naturally slaked lime paste (putty) This project has been funded with support from the European Commission. This publication [communication] reflects the views only of the author, and the Commission cannot be held responsible for any use which may be made of the information contained therein. Material is based on information from webpage www.limex.ee and on information gained from workshop in Lubjapark on 30.06.2014. For more information about lime, contact Mr Priit Penu limex@limex.ee Construction Trainers Training – CT Train AS Limex products made from local limestone Lime wash “Saaremaa Lime” (lime paint) Lubivärv This lime wash is made from high quality Saaremaa´s quicklime and water . USAGE: Painting cultural-historical objects, buildings, base of chimneys, agricultural buildings, cellars, bleaching fruit trees ect. Possible to add directly to masonry or more commonly to pre-applied lime coatings. Lime wash has a great disinfecting qualities against micro-organisms. How to use: 1. Clean the surface from dust, grease and ect. Lime wash should never be applied to a dry surface, as this will cause rapid drying out of the lime wash and result in dusting. Before and during application you have to stir the lime wash to avoid the solid paste settling in the bottom. Use for applying the lime wash special type of Lime brush or a rag/sponge, never a roller. For foundation make the solution from 2 parts of water and 1 part of lime wash. The lime wash should be applied in several thin coats. Each coat should be allowed to dry before the next coat is applied Direct number of coats depends on foundation and object. Usually on buildings 3-6 coats, on bleaching 1-2 coats. It is possible to tint the whitewash with natural earth pigments. Consumption: 3-6 m²/l Preservation: in closed container on temperature above 0°C Environmental safety: Keep away from drains, soil and water SAFETY: Wear eye and face protection. In case of contact with eyes, rinse immediately with plenty of water. This project has been funded with support from the European Commission. This publication [communication] reflects the views only of the author, and the Commission cannot be held responsible for any use which may be made of the information contained therein. Material is based on information from webpage www.limex.ee and on information gained from workshop in Lubjapark on 30.06.2014. For more information about lime, contact Mr Priit Penu limex@limex.ee Construction Trainers Training – CT Train Lime putty “Saaremaa Lubi” for making limewash (B sort) Usage: Painting the cultural-historical buildings, bleaching-disinfection farm buildings, as well fruit trees and foot chimneys. How to use: For bleaching mix the solution from 1 kg lime paste and 4 l water. For making the whitewash mix 25 kg lime paste with 120 l water (or in same ratio the smaller quantities) and leave overnight under cover. Before use, remove the film on the surface of the solution and mix thoroughly, and then the color is usable. During use, the solution should be constantly stirred. Plaster and grout lime Usage: Lime paste for less demanding bleaching works (farm buildings, etc.) and to make various lime grouts and lime plasters. Lime grout typically consists of a binder (lime paste) and aggregates (sand, limestone flour). We recommend two most common recipes: -traditional lime grout 1:3 1 part of lime paste and 3 parts of sand (preferably coarse sand fraction, or 0-4mm 1-3), which must be thoroughly mixed minimum of 15-20 minutes. In the case of a coarser sand, lime may be added in less, if a finer sand, then more. -traditional lime grout 1: 1. It is composed of 25kg paste and 38kg limestone flour, preferably fraction 1-3) and 50 kg of sand. Components mix well. GUIDE FOR using the traditional LIME GROUT Wet grout mixture of high quality grout sand and lime paste for inner and exterior finishing works. Usage Inner finishing works – all traditional plaster surfaces (brick, concrete, lightweight concrete, Reed, covered with wood lath). This project has been funded with support from the European Commission. This publication [communication] reflects the views only of the author, and the Commission cannot be held responsible for any use which may be made of the information contained therein. Material is based on information from webpage www.limex.ee and on information gained from workshop in Lubjapark on 30.06.2014. For more information about lime, contact Mr Priit Penu limex@limex.ee Construction Trainers Training – CT Train This project has been funded with support from the European Commission. This publication [communication] reflects the views only of the author, and the Commission cannot be held responsible for any use which may be made of the information contained therein. Material is based on information from webpage www.limex.ee and on information gained from workshop in Lubjapark on 30.06.2014. For more information about lime, contact Mr Priit Penu limex@limex.ee Construction Trainers Training – CT Train Thickness of grout layer At one time, it is recommended to plaster layer of not more than 1 cm. The total thickness of the layer can be up to a couple of (example 8) cm (traditional houses). The thicker layer of plaster is recommended to exterior facade. Grouting/Plastering Before applying the grout to highly absorbent mineral surfaces you have to damp well down the surface with clean water or lime water. Damped surfaces are then ready for grout. Grout can be applied either manually or by spraying. Lime grout needs to dry slowly - avoid drafts and direct sunlight shining on the wall. Lime requires for carbonation from the air carbon dioxide and water. Grouts which are not too compressed have better carbonation features. Entering the air gets into the pores with the carbon dioxide, which is an important quality for hardening. The first grout layer will not be smoothed and it should be relatively thin, 5-6 mm. It is advisable to moisten the surface during the drying time at least once a day. Also, before the next coat of grout the lower surface of the grout should be damped. The next layer can be to laid if the previous layer is hardened, ie ca 24 h later. It is always recommended to plaster at least two layers, even in case of thinner layers of grout as it facilitates the final processing of the last layer. Consumption: 1 cm layer - ca 17 kg/m2 Final finishing: Grout is recommended to finish with traditional white wash or marble-white wash or casein paint. This project has been funded with support from the European Commission. This publication [communication] reflects the views only of the author, and the Commission cannot be held responsible for any use which may be made of the information contained therein. Material is based on information from webpage www.limex.ee and on information gained from workshop in Lubjapark on 30.06.2014. For more information about lime, contact Mr Priit Penu limex@limex.ee Construction Trainers Training – CT Train Workshop in Lümanda Limepark on 30th of June 2014 Inside of lime kiln Preserving old lime kiln Handmade waterbasin for cattle Bulletin board about extracting the lime This project has been funded with support from the European Commission. This publication [communication] reflects the views only of the author, and the Commission cannot be held responsible for any use which may be made of the information contained therein. Material is based on information from webpage www.limex.ee and on information gained from workshop in Lubjapark on 30.06.2014. For more information about lime, contact Mr Priit Penu limex@limex.ee Construction Trainers Training – CT Train This project has been funded with support from the European Commission. This publication [communication] reflects the views only of the author, and the Commission cannot be held responsible for any use which may be made of the information contained therein. Material is based on information from webpage www.limex.ee and on information gained from workshop in Lubjapark on 30.06.2014. For more information about lime, contact Mr Priit Penu limex@limex.ee