Airbag Project Names: Project Objective: Use gas stoichiometry to

advertisement

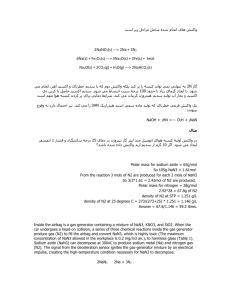

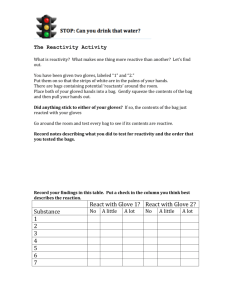

Airbag Project Names: Project Objective: Use gas stoichiometry to design a model airbag Part I. Background Information A steering wheel displaying the letters SRS (Supplemental Restraint System) is an indication of a steering wheel equipped with an air bag. If you are lucky you will never have to experience an airbag. But if you do have a front-end collision while driving, an airbag may save your life. A sensor in front of the car detects the sudden deceleration and sends a signal to a cylinder containing a mixture of chemicals. In the cylinder, an igniter goes off, starting a series of chemical reactions that release a large volume of nitrogen gas. The bag literally bursts from its storage site at up to 200 mph. The gas fills the airbag, and you hit the soft bag instead of the steering wheel or dashboard. A second later the gas quickly dissipates through tiny holes in the bag, thus deflating the bag so you can move. Engineers were challenged to produce a system that was safe and effective and that would still work after many years of not being used. Perhaps most importantly, the bag has to inflate in less than a tenth of a second, and it has to inflate with exactly the right amount of gas. If it under-inflates it would not provide enough protection; if it is over-inflated it would cause injury or it might even rupture. To design an airbag inflation system that met these requirements, engineers had to choose the right chemical reactants and pay close attention to the stoichiometry of the reactions. The inflation system that engineers settled on uses a series of chemical reactions that take place very quickly. The first reaction-set off by the igniter is the decomposition of sodium azide into sodium metal and nitrogen gas. Reaction 1: 2NaN3 → 2Na + 3N2 By itself this reaction cannot fill the airbag fast enough, and the sodium metal that is produced is dangerously reactive. To solve these problems, the engineers included potassium nitrate in the mixture of reactants. The potassium nitrate reacts with the sodium produced in the first reaction, releasing even more nitrogen gas. Reaction 2: 10Na + 2KNO3 → K2O + 5Na2O + N2 The heat released by this reaction raises the temperature of the gaseous product, helping the bag inflate even faster. The heat causes all the solid reaction products to fuse together with SiO2, powdered sand, which is also part of the reaction mixture Reaction 3: K2O + Na2O + 2 SiO2 → K2O3Si + Na2O3Si (silicate glass) Part I Questions 1. Describe two engineering challenges of designing an airbag. 2. What would happen if the airbag under-inflates or over-inflates? 3. Describe the two reasons that potassium nitrate is needed in “Reaction 2.” 4. Assume that only nitrogen from “Reaction 1” fills the airbag. Determine the mass (in grams) of sodium azide (NaN3) needed to fill an airbag in the following situations. Show all calculations. Situation A Conditions Air Temperature: 72ºF Pressure: 755 mmHg Volume of Air Bag: 65.1 L Situation B Conditions Air Temperature: 65ºF Pressure: 102.3 kPa Volume of Air Bag: 70 L Situation C Conditions Air Temperature: 80ºF Pressure: 755 mmHg Volume of Air Bag: 62 L Situation D Conditions Air Temperature: 72ºF Pressure: 761 torr Volume of Air Bag: 71 L Part II. Construct an Airbag Using a Plastic Bag, Vinegar, Sodium Bicarbonate In this part of the project, you will use a small plastic bag to model an airbag. Rather than use the toxic sodium azide (NaN3), we will use baking soda (sodium bicarbonate) and vinegar (acetic acid). In order to determine the amount of each reactant needed, you will need to first know the volume of the bag. 1. Describe a way that the plastic bag volume can be determined. 2. After using the method described in question 1, what is the volume of your bag? 3. Write the balanced reaction between vinegar (acetic acid) and baking soda (sodium bicarbonate) 4. Determine the number of moles of carbon dioxide needed to fill the bag Temperature of Room: Atmospheric Pressure: Volume of Bag: Moles of CO2 needed: 5. Determine the mass (in grams) of baking soda needed to produce the amount of carbon dioxide you calculated in number 4. 6. Determine the volume (in mL) of vinegar you will need to produce the amount of carbon dioxide you calculated in number 4. The molarity of acetic acid is 0.87mol/L. Part III. Airbag Design 1. Design and describe the method you will use to inflate you airbag. Run the reaction! 2. Describe one specific way that your methods could be improved to achieve a better inflation of the bag.