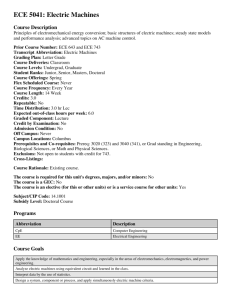

Electromechanical Product Engineer (Design And Develop

advertisement

Electromechanical Product Engineer This person performs Product Design and Launch Engineering for electromechanical systems and electromechanical actuators. Must have progressive experience with complex mechanical, electromechanical and electrical/electronic systems and ability to put into production new EMAs and maintain and upgrade existing EMA product. General Work Description: -Performs engineering design evaluations for developing a range of products and systems. Ensures electromechanical engineering projects, initiatives, and processes are in conformance with organization's established policies and objectives. -Use advanced theory, mathematical, scientific or engineering principles to solve problems, conduct testing, prepare documentation or create applications or devices in the completion of their work. -Works closely with Director of Engineering, Systems Engineering, Product Development and Test Engineering, and Quality and Manufacturing groups to launch products and improve existing products. -Knowledgeable in 6 Sigma and Lean Manufacturing techniques. -Recommends alterations of design to improve quality of products and or procedures. -Requires at a minimum bachelor’s degree in electrical engineering or electromechanical engineering and 5+ years experience and in the field with progressively more sophisticated experience in complex mechanical, electromechanical and electrical/electronic systems. Thorough understanding of motor drive systems, controls, and instrumentation. Familiar with standards concepts, practices, and procedures within field. Relies on experience and judgment to plan and accomplish goals. The applicant must also have the requisite skills to perform in all phases of hardware design, development, and documentation. An understanding of facility and/or industrial equipment, electrical diagrams and schematics, and power systems preferred. Knowledge of electrical codes also desired. -Completes prototype and production launch process implementation, integrating R & D work into new products. -Work with the customer on a technical level as required. -Drive efficient improvements using predictive tools and reporting. -Includes multi-plant/multi-vendor coordination of product development. Responsible for design, development, and analysis of technical products and systems. Performs engineering design evaluations. May develop a range of products. -Responsibilities include full design responsibility for project encompassing: -electromechanical design and layout including proper tolerances -system modeling and hardware in the loop knowledge -knowledge of kinematics and modeling of such -use of Matlab and Simulink desired -creation of drawings -integrating purchased equipment from vendors into the overall design -communicating with the customer’s design personnel to assure the proper CAD information flow -Working with internal personnel to assure consistency with internal processes and procedures -Implementing launch process and putting electromechanical devices into production following APQP style process -Generation of detailed Statement of Work documentation and formation of specifications -Create and maintain product launch documentation (ECN, Test Results, Engineering Drawings, Dimensional Data, Process Flow, Logic Diagrams, FMEA, Control Plan, etc.) -Implement Design For Six Sigma considerations, and verification that equipment and process will meet quality requirements, including writing, and executing run-off criteria -Assuring that the process reaches short and long term process capability -intimately interfacing with suppliers to assure that purchased equipment meets specifications, and developing and executing contingencies or reaction plans if it does not to still meet timing and quality in the interim. -Working closely with customer to understand and assure that the process is able to meet customer and product needs. -Change management as the project evolves to include improvements as details are finalized and maintaining revision control to assure that the latest information is what the group is operating to. -Cell startup and debug and troubleshooting -Establish and meet reliability goals so that the product launch is at low risk -Implement continuous improvement and develop new processes for cost outs and process efficiency improvements -Write work instructions and train labor force personnel in assembly/manufacturing. -Quality assurance work in the manufacturing cell and assuring that the applicable plant processes as well as required new processes are in place. -Quality work with suppliers to assure that the designs, process, materials, and systems meet requirements. -Some level of Gage design, sourcing, implementation, end-of-line tester design, and production startup. -Support Sourcing and Purchasing function for sourcing and ERP, and vendor development. -Specification writing. -Continuous DFMEA and PFMEA work and integrating control plans and work instructions with latest state of process and product design. -Troubleshooting. -Equipment design, capability analysis and improvement. -MSA, SPC, DOEs, RCA considerations during the design, startup, and proveout of the product and cell, and during product maturity phase where processes may change and cost-outs occur but quality product still needs to be made, including new vendor development. -Provides technical direction to support personnel.