Lab Report (PP.9) 457

advertisement

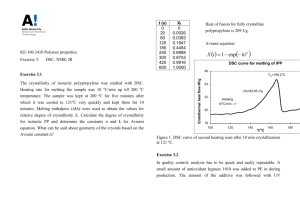

1 Polypropylene Phase Transitions Studied by DSC By: Ryne Sternberg Sean McCrea, Adam Bielski Pennsylvania State University Due October 23rd 2014 Abstract: Isotactic and Amorphous polypropylene were studied through Differential Scanning Calorimeter (DSC). When analyzing amorphous polypropylene, both first order and second order transition phases are observed with an enthalpy of crystallization of 13.22 J/g. This shows the sample was not 100% pure. The glass transition temperature was found to be -12.68°C. The degree of crystallinity for the amorphous sample was calculated for a value of 6.83%. The isotactic sample had a degree of crystallinity at 41.2% as well as an enthalpy of crystallization of 85.32 J/g. The entropy of the glass transition phase was calculated through a series of integrals ranging from ±20°C, this value was 1.58 J/mol-K. The entropy of crystallization was 0.20 J/mol-K, this was calculated through utilization of the first law of thermodynamics. This experiment demonstrated differences between stereochemistry in molecules, which showed differences in thermodynamic properties of two isomers of polypropylene. 2 INTRODUCTION: Differential Scanning Calorimetry (DSC) is used to determine and compare the phase transitions of both amorphous and isotactic polypropylene. 2Differential scanning calorimeters are a widely used thermoanalyitcal instruments due to their ease of use, relatively fast data collection times and ability to use small sample sizes.3DSC is used to measure thermal properties of nanocomposite thermal-plastics widely used in the engineering of polymers. Polymer engineering is important due to the demand on innovative ways to create plastic. Using DSC can give thermodynamic properties, which help engineers produce plastics that can resist high or low temperatures. DSC works by measuring the heat flow to or from a sample when chemical or physical changes occur during applied temperature increase. When there is no chemical or physical change total heat is calculated by: 𝑞𝑝 = 𝐶𝑝 ∆𝑇 (1) Cp is independent of temperature and ΔT is the temperature change. If there is any excess heat transferred in the system equation 1 turns into: 𝐶𝑝,𝑒𝑥 = 2The 𝑞𝑒𝑥 ∆𝑇 (2) excess heat can be viewed, as the change in heat capacity therefore the DSC thermogram is essentially a chart of Cp,ex vs. T. When the system undergoes any chemical or physical changes a peak forms on the graph. These peaks can be integrated to find enthalpy of transition. The integration is shown in Equation 3. 𝑇2 ∆𝐻𝑝 = ∫𝑇1 𝐶𝑝,𝑒𝑥 𝑑𝑇 (3) 3 T1 and T2 represent the beginning and ending temperatures of transition. There are two different types of transition being studied in this lab. First order and second order transition. A steep peak in the high temperature range represents first order transition, this demonstrates crystallization. Slow rising peaks in the lower temperature range represent second order. It is hypothesized before lab that the amorphous polypropylene would only show second order transition. This is due to its tacitcity, which is related to the stereochemistry of a molecule. 1Tacticity is a term used to describe the way pendent groups on a polymer chain are arranged on a polymer backbone. 1The tacticity of a polymer is determined by what side of the polymer chain the pendant groups are on. Amorphous Polypropylene is a long carbon chain where each center carbon is connected to a methyl group and hydrogen; these are situated in random order. This random order of side groups forms an amorphous solid that does not crystalize. Isotactic Polypropylene has all methyl groups in the same position from the center carbon, which allows it to crystalize. These phenomena’s are studied through the graphs produced by DSC. 1st order transition occurs when the molecule crystallizes with an applied heat flow, thus represent Isotactic Polypropylene. Amorphous Polypropylene was predicted to only form second order transition because it does not crystallize. After observing the different peaks of transition the entropy will be calculated through the integral shown in Equation 4. 𝑇2 𝐶𝑝 ∆𝑆 = ∫𝑇1 𝑇 𝑑𝑇 (4) 4 The first law of thermodynamics shown in equation 5 helps shape an understanding of the system and is used for calculations of entropy when the Gibbs free energy is zero. ∆𝐺 = ∆𝐻 − 𝑇∆𝑆 (5) EXPERIMENTAL: The pressure of the nitrogen (CAS 7727-37-9) feed was set to 20 psi, exceeding this pressure would damage the instrument. Q200-1724 was then opened on the computer monitor. The cell was set to room temperature with a sample purge flow rate of 50mL/min. Amorphous Polypropylene; Aldrich (CAS 9003-07-0) was then placed in DSC Q2000 differential scanning calorimeter. There are three Hermetic Tzero aluminum sample pans in which the polymer samples sat on for the experiment. It was essential to use tweezers when handling the samples; this prevented any skin oil interaction, which would affect results. A simplistic diagram of the system is shown below. Figure 3: Diagram of Experiment Attained from http://pslc.ws/macrog/dsc.htm 5 The sample and reference pan are both placed on top of two thermocouples inside the cell. The computer was set to 9.3 mg for PPA_56, which was the sample being tested. After all experimental constraints were confirmed the experiment started. DSC graphs were made from the Q200-1724 program and integrated to find enthalpy of transition. The Data for the PPC was attained from other sources after completion. RESULTS: Figure 4: PPA_54 DSC thermogram 6 Figure 4 represents the graph created from the DSC. It is observed that both 1 st order and 2nd order transitions take place in the “supposed” amorphous polypropylene. An average of the heating and cooling peaks gave a glass transition temperature of -12.68°C. The first order crystallization peak had an enthalpy of 13.22 J/g with a melting temperature of 137.69°C. The degree of cystallinity was reported at 6.83%. Figure 5 represents the thermogram for Isotactic Polypropylene. Figure 5: PPC_54 DSC Thermogram The enthalpy of crystallization of isotactic polypropylene is 85.32 J/g at a temperature of 151.65°C. The degree of crystallinity is 41.2%. The graph is symmetrical showing no glass transition. The entropy of crystallization is calculated using the first law of thermodynamics and has a value of 0.201J/g-K. Figure 6 7 represents Entropy vs. Temperature of glass transition during the scanning of Amorphous Polypropylene. Entropy vs Temperature 1.8 1.6 S(J/molK) 1.4 1.2 1 0.8 0.6 0.4 0.2 0 250 260 270 280 Temperature (K) 290 300 Figure 6: Entropy vs. Temperature. This figure represents the change in Entropy dependent on temperature. Each point corresponds to its individual integrals with a range of -20°C to 20°C. The max value gives the sum of all individual integrals as a value 1.58 J/g-K, this is the entropy associated with glass transition. DISCUSSION: Figure 4 demonstrated the “supposed” pure amorphous polypropylene. After witnessing the crystallization peak at 137.69°C, it is proved that the sample used was not 100% pure. The degree of crystallinity was calculated using a reference 8 enthalpy of crystallization as 207 J/g and a value of 6.83% was reported. Since the sample was not 100% pure it could not dissolve properly which caused a small portion crystallized. In future if this sample was used, believing it was 100% pure, there would be a significant amount of error when creating products. This is can cause failure to future reactions and their products and would lower the percent yield of a target chemical. 2The melting temperature of amorphous polypropylene is reported to be 160-165°C and a transition temperature of -10°C, these values were obtained from Sigma Aldrich. Figure 4 gives values slightly off from literature values. On a molecular level the bonds released at lower temperatures, a melting temperature is observed at 152.57°C. This could be caused by inconsistency of pressure during the experiment. The pressure of the cell could have fluctuated, since the melting temperature was reported lower then ideal, it is assumed that the pressure decreased. 4This assumption is made due to the direct relationship between pressure and temperature, when pressure is decreased so does the melting point. Also the discrepancy could have been caused by too rapid of increase in temperature. If temperature increases faster then the DSC can read, the melting temperature will be recorded lower then ideal. Isotactic polypropylene reports a higher melting temperature of 189°C, this value is found in the chemical book website.2Since this melting point is slightly higher then amorphous this proves that a consistent stereochemistry within a molecule gives a stronger bond between carbon and its corresponding R group. Using this phenomena when comparing both Isotactic and Amorphous polypropylene, it shows 9 the bonds are either closer together or attracted to each other more when stereochemistry is the same for all carbons, the isotactic polypropylene. The temperature range for the peak of crystallization varied when comparing the amorphous to isotactic polypropylene. The wider the temperature range and ultimately wider the peak corresponds to more crystallization enthalpy of the molecule. In the amorphous sample, the crystallization peak was much thinner than the isotactic sample. This agrees with the values of enthalpy of each, the isotactic had a much higher enthalpy compared to amorphous. This shows the isotactic sample involved a greater temperature range during the crystallization physical change. The entropies of both amorphous and isotactic sample differed significantly. Entropy is defined as the disorder or randomness of a system. This is demonstrated in both Figure 4 and 5 and it corresponds with their entropy values. When looking at the glass transition phase the temperature changes at many different points of heat flow. This is the reason for the calculation of the integral ranging from -20 to 20°C. The sum of those gives a value of 1.58 J/g-K. As the temperature changes so does the disorder of the system. The entropy of the isotactic sample gave a value of 0.201 J/g-K, this is significantly lower then the amorphous sample because temperature stays at a constant value, the melting temperature. The first law of thermodynamics can be applied and the total energy in the system is equal to the enthalpy of crystallization, which gives lower disorder thus lower entropy. 10 CONCLUSION: Differential scanning calorimeter was used to test both amorphous and isotactic polypropylene. The DSC thermogram showed that the amorphous polypropylene was not 100% pure; this was evaluated through both its predicted glass transition phase as well as its 6.83% crystallization 1st order peak with an enthalpy value of 13.22J/g. The temperature of glass transition was an average of both hot and cold temperatures and was a value of -12.68 °C. Pure amorphous polypropylene would not exhibit a 1st order peak. The entropy of the glass transition was calculated through a series of integrals, which gave a value of 1.58 J/g-K. The entropy of crystallization, observed in the isotactic thermogram was a value of 0.20 J/g-K. The degree of crystallization was 41.2 %. The variances between both the isotactic and amorphous sample are due to its stereochemistry and strength of bonds. The more consistent a structure the stronger its bonds are. Differences from ideal values could have occurred from rapid temperature increase or decrease in cell pressure. DSC proves to be a powerful tool when studying thermodynamic properties of isomers and helps compare and contrast small differences within each compound. ACKNOWLEDGMENTS: I would like to thank Sean McCrea, Adam Bielski and Professor M for their help with configuration and understanding of this experiment. REFERENCES: 1) O'Lenick, Anthony. Comparatively Speaking: Isotactic vs. Syndiotactic vs. Atactic in Polymers. 2009. 2) Milosavljevic, Bratoljub. Lab Packet for Experimental Physical Chemistry. 2013, 9(1)-9(6). 3) Polymer Engineering Science. Vol 54.,pp 2292-2300 4) Ewen, John. J. Am. Chem. Soc., 1984, 106 (21), pp 6355–6364 11