CAD224_Apr2012 - Heartland Community College

advertisement

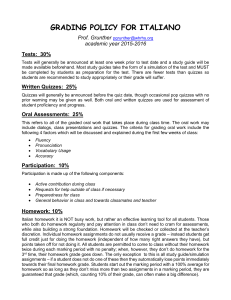

Heartland Community College Master Course Syllabus Division name: Course Prefix and Number: Course Title: DATE PREPARED: DATE REVISED: PCS/CIP/ID NO: TECH CAD 224 Geometric Dimensioning and Tolerancing December 1, 1999 March 27, 2012 1.2- 151303 IAI NO. (if available): EFFECTIVE DATE OF FIRST CLASS: August 16, 2012 CREDIT HOURS: CONTACT HOURS: LECTURE HOURS: 3 4 2 LABORATORY HOURS: 2 CATALOG DESCRIPTION (Include specific prerequisites): Prerequisite: CAD 110. Geometric Dimensioning and Tolerancing focuses on applying geometric dimensioning and tolerancing principles in product design. Topics include the standard definitions, print designation, datum reference frame, and tolerances of location, form, profile, orientation and runout. Advanced concepts include a study of bonus tolerances, virtual conditions and datum references. TEXTBOOKS: Madsen, D. A. (2010) Geometric Dimensioning and Tolerancing: Based on ASME Y14.52009 (8th Ed.). Tinley Park, IL: Goodheart-Willcox Company, Inc. Or a comparable text that addresses at a minimum the topics listed in the Course/Lab Outline and that provides students with the opportunity to achieve the Learning Outcomes for this course. RELATIONSHIP TO ACADEMIC DEVELOPMENT PROGRAMS AND TRANSFERABILITY: CAD 224 was designed to meet the specific needs of an Associate of Applied Science degree. Please see an academic advisor for an explanation concerning transfer options. LEARNING OUTCOMES: Course Outcomes: General Education Outcomes Range of Assessment Methods 1. Understand drafting standards and conventional practices. 2. Create CAD drawings using descriptive geometry. PS3, CO2 3. Set dimension variables and add dimensions to CAD drawings. PS3 4. Demonstrate the solutions to the problems of 3D spatial geometry as solved in 2D planes such as drawing surfaces. 5. Use a CAD system to create orthographic projections of points, lines and planes. 6. Demonstrate the solutions of vectory analysis as applied to a variety of geometric relationships. 7. Perform graphical analysis of various mathematical problems through the use of CAD software. 8. Interpret ANSI standards related to geometric dimensioning and tolerancing. 9. Distinguish between ANSI and ISO standards. PS2 PS2 PS2 10. Identify inspection methods used in geometric tolerance applications. 11. Determine tolerance effects on product design. PS2 12. Understand the application of geometric dimensioning and tolerancing to simple engineering drawings. 13. Apply the correct symbols and related terminology to basic parts. PS2 14. Understand the virtual conditions created by the design specifications. 15. Understand the basis for functional written work, lab assignments/final project, and quizzes/tests written work, lab assignments/final project, and quizzes/tests written work, lab assignments/final project, and quizzes/tests written work, lab assignments/final project, and quizzes/tests written work, lab assignments/final project, and quizzes/tests written work, lab assignments/final project, and quizzes/tests written work, lab assignments/final project, and quizzes/tests written work, lab assignments/final project, and quizzes/tests written work, lab assignments/final project, and quizzes/tests written work, lab assignments/final project, and quizzes/tests written work, lab assignments/final project, and quizzes/tests written work, lab assignments/final project, and quizzes/tests written work, lab assignments/final project, and quizzes/tests written work, lab assignments/final project, and quizzes/tests written work, lab gages in the applications of positional tolerancing. assignments/final project, and quizzes/tests COURSE/LAB OUTLINE: 1. Drafting standards and conventional practices 2. Standard definitions 3. Print designation 4. Datum reference frame 5. Tolerances of location, form, profile, orientation and runout 6. Bonus tolerances, virtual conditions and datum references METHOD OF EVALUATION (Tests/Exams, Grading System): Course evaluations may be based on written work (5-20%), lab assignments/final project (6075%), and quizzes/tests (20-35%). Heavier evaluation emphasis will be placed on activities requiring hands-on use of software/equipment. More specific methods of evaluation will vary by instructor. Course grades will be determined by the use of the following grading scale: A 90-100% B 80-89% C 70-79% D 60-69% F Below 60% REQUIRED WRITING AND READING: There will be assigned readings throughout this course. There will be at least one writing assignment to be completed in this course.