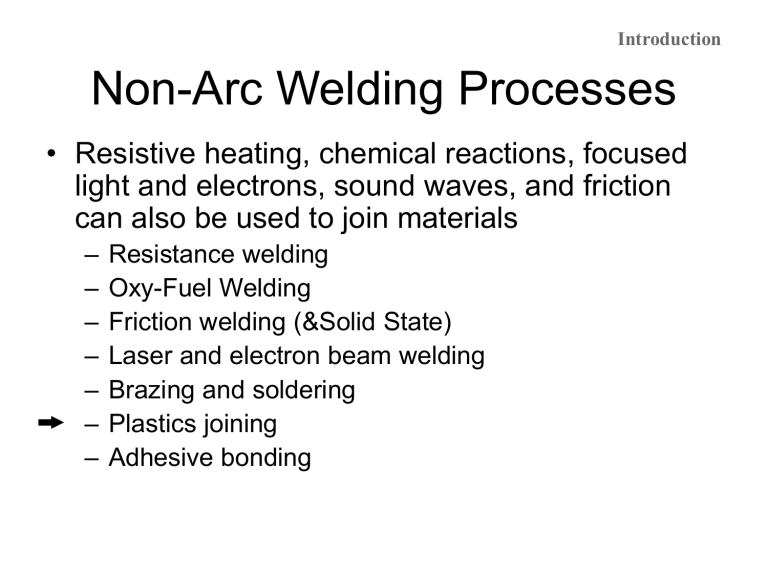

Non-Arc Welding Processes

Introduction

Non-Arc Welding Processes

• Resistive heating, chemical reactions, focused light and electrons, sound waves, and friction can also be used to join materials

– Resistance welding

– Oxy-Fuel Welding

– Friction welding (&Solid State)

– Laser and electron beam welding

– Brazing and soldering

– Plastics joining

– Adhesive bonding

Welding of Plastics

Joining Plastics

• Polymer - a single building block (mer) is repeated to form a long chain molecule

– Thermoplastic polymers soften when heated, harden when cooled

• 2-liter bottles

– Thermosetting polymers don’t soften when heated

• Car tires, caulking compound

H

H

(Poly)ethylene

C=C

H

H add H

2

O

2

···

H H

-C-C-

H H

···

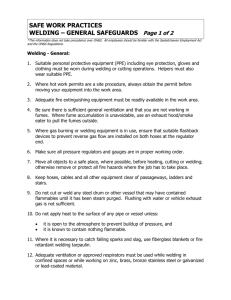

Hot Plate, Hot Gas, Infrared

• Advantages

– Provide strong joints

– Reliable

– Used on difficult to join plastics

• Limitations

– Slow

– Limited temperature range

0.1.1.2.5.T23.95.12

Welding of Plastics

Hot Plate, Infrared Welding

Hot plate welding

Hot Gas Welding

• Thermoplastics

(hotmelts)

– Adhesive is heated until it softens, then hardens on cooling

• Hot gas softens filler and base material

• Filler is pulled or fed into the joint

Welding of Plastics

Vibration

• Advantages

– Speed

– Used on many materials

• Limitations

– Size

– Requires fixturing

– Equipment costly

0.1.1.2.5.T24.95.12

Ultrasonic

• Advantages

– Fast

– Can spot or seam weld

• Limitations

– Equipment complex, many variables

– Only use on small parts

– Cannot weld all plastics

0.1.1.2.5.T25.95.12