IMS 1.0

Intelligent Mining Software “Solutions”

IMS - Model Updating with Flitch

Polygons

Produced by W.S. Mart and G. Markey

For MineMap Pty Ltd

Intelligent Mining Software “Solutions” IMS - Model Updating with

Flitch Polygons

Copyright © 2013 by William Seldon Mart and Geoff Markey. All rights reserved.

Page 1

Intelligent Mining Software “Solutions” IMS - Model Updating with

Flitch Polygons

Table of Contents

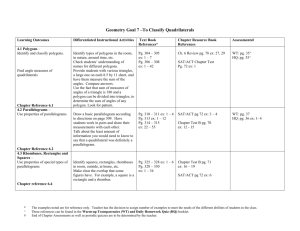

CREATING FLITCH BARS AND FLITCH INTERPRETATIONS .............................................. 3

Generating Flitch Bars .............................................................................................................................. 3

Interpretation of Flitch Polygons ......................................................................................................... 4

Change to Plan View .................................................................................................................................. 4

Draw Flitch Interpretation Polygons .................................................................................................. 5

WRITE OUT DRILLHOLE DATA THAT LIES WITHIN PODS ................................................ 6

MODELLING PROCESS .................................................................................................................... 8

Concept .......................................................................................................................................................... 8

Using Flitch Plans ....................................................................................................................................... 8

Setting the Region ...................................................................................................................................... 9

Model Processes ......................................................................................................................................... 9

Page 2

Intelligent Mining Software “Solutions” IMS - Model Updating with

Flitch Polygons

CREATING FLITCH BARS AND FLITCH INTERPRETATIONS

The interpretation of the orebody in section view needs to be transferred to a plan view interpretation

for block model interpolation. This is done by creating horizontal drillhole (flitch) bars that represent

the intersection of your sectional polygons at a particular plan view elevation. The following example

leads you through the procedure.

Generating Flitch Bars

1. Load the CAD file 'pods.svy' by dragging in to 3D view.

2. Make sure that the front view is shown. This is easily achieved by selecting <Section View Front> from the toolbar.

3. Select <Show All Data> from the toolbar to display all your drillholes and sectional ore

outlines.

4. Select the <Drillholes><Generate><Flitch Bars…> from the menu to display the flitch bar

dialog box (see Figure 1).

Figure 1: Parameters for flitch bar generation

Here we are creating a IMS drillhole file called ‘bars.dhl’.

Enter “427.5” for the minimum elevation (our lowest bench was nominated as 430 in model

definition, ‘gold.mod’). Note that the flitch bars must be created at the mid-bench elevation.

Enter “5.0” in the increment field, which will result in the drillhole bars being created from

the 427.5m elevation, every 5.0m, within the sectional polygons.

5. Load the new drillhole file ‘bars.dhl’ by dragging in to 3D view.

Page 3

Intelligent Mining Software “Solutions” IMS - Model Updating with

Flitch Polygons

Interpretation of Flitch Polygons

Once you have created the horizontal drillhole bar file (‘bars.dhl’) and are satisfied that it is correct,

you need to interpret flitch polygons on each bench. This is done in plan-view for every bench level at

which you want to interpret your orebody.

This is done at every 5.0m, viewing in plan-view, and polygons will be drawn enclosing the drillhole

bars, representing the interpretation of the ore zones on that particular 5m bench.

You will need to create a polygon(s) for each bench level starting at the 527.5m RL, to the 437.5m

RL, every 5m.

Change to Plan View

1. If you are still in section view from the previous exercise, select <Plan View - Up> from the

toolbar.

2. Select <Show All data> from the toolbar to make sure all drillholes are displayed.

3. Select <View><Viewing Slice><Setup and Use Plan View Slice…> from the menu to

display the slice parameters dialog box (see Figure 2)

Figure 2: Parameters for plan view slice

Enter 527.5 for the RL, a search distance of 2.5 and a translation distance of 5. This ensures

that the view plane is on the 527.5 RL and data that is 2.5m either side of the RL will be

displayed. Whenever you press the slice in or out buttons, the window will move in or out by

the translation distance.

Page 4

Intelligent Mining Software “Solutions” IMS - Model Updating with

Flitch Polygons

Draw Flitch Interpretation Polygons

1. Right-click in the Loaded Files Pane and select <New CAD Layer…> from the context

menu.

2. Rename the file to “flitches”.

3. Select <Strings><New…> from the menu.

4. Choose the Polygon radio button in the resulting dialog box. All the other fields in the dialog

box can be left as is.

5. Create the polygon in the 3D Pane. Start with free hand drawing, then use <Tools><Snap><

To a Drillhole> to accurately define the perimeters of the ore zones (see Figure 3).

Figure 3: Flitch polygon around the ore zone

6. Once you have finished outlining the ore for this bench save the flitch interpretation by

selecting <Save> from the context menu in the Loaded Files Pane.

7. Move the viewing slice down to the next plane by selecting <Move Viewing Slice In> from

the toolbar.

8. Repeat steps 3 to 7 for all the remaining flitches. You will then have a CAD file with flitches

from 517.5m RL to 437.5m RL.

Page 5

Intelligent Mining Software “Solutions” IMS - Model Updating with

Flitch Polygons

WRITE OUT DRILLHOLE DATA THAT LIES WITHIN PODS

The modelling process only requires drillhole data that lies within your interpreted sectional polygons.

Data outside these polygons is classified as “waste” while the data inside the polygons is classified as

“ore”.

Although the modelling and interpretation of the orebody takes place in plan-view (flitches or

benches), the ellipsoidal algorithm (set in the model definition) searches in all three dimensions for

drillhole data to calculate the grade of a cell. To ensure the samples outside the orebody

interpretations made in section view are not included (which would result in the down grading of cell

values) the drillhole, or ore, data inside the polygons must be written to a new drillhole file.

1. Load ‘gold.dhl’ and ‘pods.svy’. The drillholes and the polygons representing your orebody

for the first section should now be displayed.

2. Make sure you are in plan-view.

3. Select <View><Viewing Slice><Setup and Use Section View Slice> and draw a line to

roughly indicate the required section. The section slice dialog box will then ne displayed (see

Figure 4).

4. Refine the section slice by modifying the values in the section slice dialog box. Here we

select the section at 3650N.

Figure 4: Parameters for section view slice

Page 6

Intelligent Mining Software “Solutions” IMS - Model Updating with

Flitch Polygons

5. Select <Drillholes><Write Within Polygon…> from the menu and fill in the dialog box (see

Figure 5).

Figure 5: Selecting condition for samples

6. Select the required polygon(s) in the 3D Pane. The drillholes within the polygons will be

written to the drillhole file you specified.

7. Move the viewing slice to the next section selecting <Move Viewing Slice In> from the

toolbar.

8. Repeat steps 6 and 7 for all remaining sections.

9. To end the process and finalize the drillhole file press the ‘Esc’ key.

Page 7

Intelligent Mining Software “Solutions” IMS - Model Updating with

Flitch Polygons

MODELLING PROCESS

Modelling takes place in plan-view using the subset of drillhole data (‘ore.dhl’) within the

interpolated sectional polygons and flitch plans. The combination of these two sets of data is used to

update cell in an empty block model (‘gold.mod’) using the ‘ellipsoidal IDW’ algorithm.

Concept

The concept of block modelling is to create regular mining units (ie. cells) that represent the ore

deposit. Since the deposit has been delineated between widely spaced drillholes (25m spaced sections)

the selective mining units (in this case 2.5 x 5.0 x 5.0m blocks) will have their values changed from

the nominated waste values to an algorithmically interpolated value.

The flitch polygon interpretations of the orebody on each flitch will determine which cells will be

updated by the algorithm. The subset of drillhole data, (ie. the drillhole data that lies within the ore

zones in section) will be the database from which the algorithm will calculate the value for the cells.

Using Flitch Plans

1.

2.

3.

4.

Load ‘flitches.svy’, ‘ore.dhl’ and ‘gold.mod’ to the 3D Pane.

Select <Plan View – Top> from the toolbar.

Select <Show All Data> from the toolbar to show all flitches and drill data in the 3D Pane.

Select <View><Viewing Slice><Setup and Use Plan View Slice> from the menu and set the

plane of elevation to the mid bench of the top flitch interpretation (527.5m) with a window of

2.5m. Set a translation distance of 5m (see Figure 6).

Figure 6: Parameters for plan view slice

Page 8

Intelligent Mining Software “Solutions” IMS - Model Updating with

Flitch Polygons

Setting the Region

If you have more than one polygon visible then you need to define a region so that multiple polygons

can be modelled in one operation. Here we require all visible polygons so choose <Region><Screen

Area> from the menu.

Model Processes

1. Select <Model><Update Cells><Setup> to display the update parameters property sheet (see

Figure 7).

Figure 7: Parameters for stratigraphy updating

Here we are operating on the 530 bench since you have set up the viewing slice for this level.

We are also operating on the block model directly. Surface files are only used with laminar

models.

Page 9

Intelligent Mining Software “Solutions” IMS - Model Updating with

Flitch Polygons

2. Select the Method tab and set the grade calculation method for the bench (see Figure 8).

Figure 8: Selecting grade calculation parameters

Here we specify All samples, length weighted, triangles weighted by area (the default grade

calculation method). This ensures that the grade calculation (Ellipsoidal IDW) will search for

all drillhole data displayed on the screen, irrespective of whether the data lies inside or

outside of the polygons. This is done because you have previously written out the drillhole

data subset of ore data (ie. only data within the sectional interpretation polygons) to model

using the quasi wireframe method of modelling.

3. Commence the updating process by selecting <Model><Update cells><Update> from the

menu.

Page 10

Intelligent Mining Software “Solutions” IMS - Model Updating with

Flitch Polygons

4. Move the viewing slice by selecting <Move Viewing Slice In> from the toolbar.

5. Select <Model>< Update Cells ><Setup> to change the updating bench & select only “525”

from the list.

6. Select <Model><Update Cells><Update> to update the model cell values for that bench.

7. Repeat steps 4 through 6 for the remaining benches.

NOTE: The modelling process is an integration of three file formats: the IMS CAD file

(‘fliches.svy’) which defines which cells for that bench will have their values changed; the

drillhole data subset (‘ore.dhl’) which determines what drillhole data is used to interpolate the

cell’s value; and the model file itself (‘gold.mod’).

Page 11