RSC Communication Template (Version 3.2)

advertisement

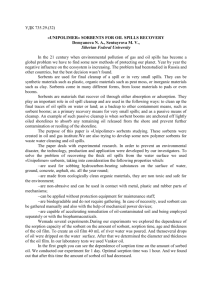

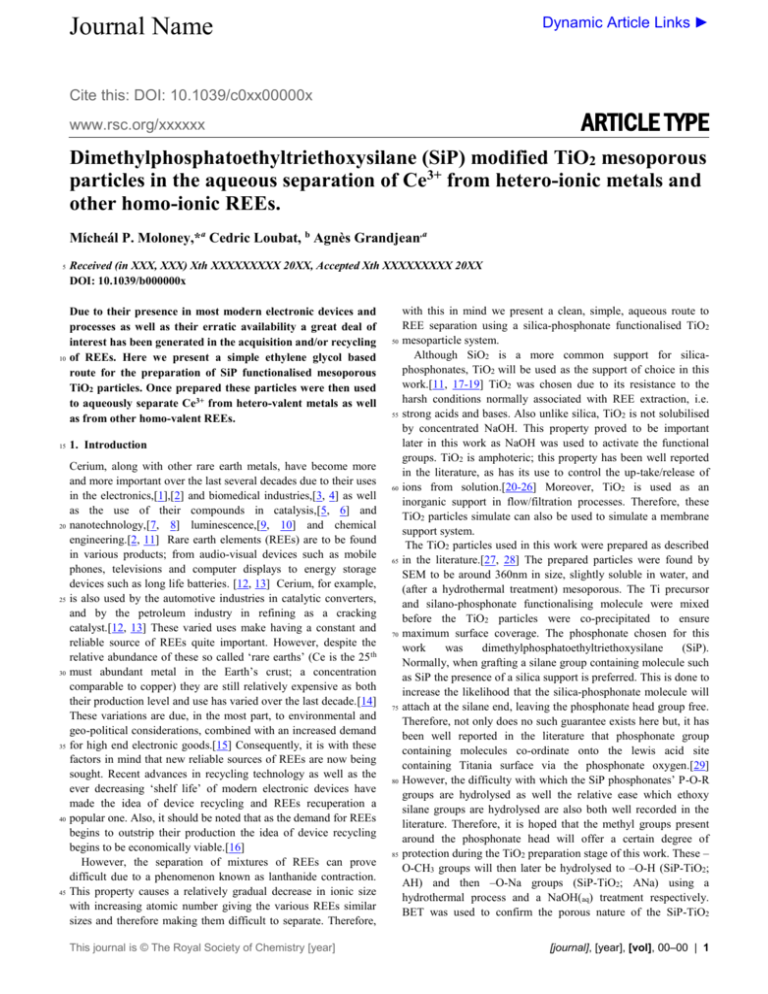

Dynamic Article Links ► Journal Name Cite this: DOI: 10.1039/c0xx00000x ARTICLE TYPE www.rsc.org/xxxxxx Dimethylphosphatoethyltriethoxysilane (SiP) modified TiO2 mesoporous particles in the aqueous separation of Ce3+ from hetero-ionic metals and other homo-ionic REEs. Mícheál P. Moloney,*a Cedric Loubat, b Agnès Grandjean,a 5 10 15 20 25 30 35 40 45 Received (in XXX, XXX) Xth XXXXXXXXX 20XX, Accepted Xth XXXXXXXXX 20XX DOI: 10.1039/b000000x Due to their presence in most modern electronic devices and processes as well as their erratic availability a great deal of interest has been generated in the acquisition and/or recycling of REEs. Here we present a simple ethylene glycol based route for the preparation of SiP functionalised mesoporous TiO2 particles. Once prepared these particles were then used to aqueously separate Ce3+ from hetero-valent metals as well as from other homo-valent REEs. 50 55 1. Introduction Cerium, along with other rare earth metals, have become more and more important over the last several decades due to their uses in the electronics,[1],[2] and biomedical industries,[3, 4] as well as the use of their compounds in catalysis,[5, 6] and nanotechnology,[7, 8] luminescence,[9, 10] and chemical engineering.[2, 11] Rare earth elements (REEs) are to be found in various products; from audio-visual devices such as mobile phones, televisions and computer displays to energy storage devices such as long life batteries. [12, 13] Cerium, for example, is also used by the automotive industries in catalytic converters, and by the petroleum industry in refining as a cracking catalyst.[12, 13] These varied uses make having a constant and reliable source of REEs quite important. However, despite the relative abundance of these so called ‘rare earths’ (Ce is the 25 th must abundant metal in the Earth’s crust; a concentration comparable to copper) they are still relatively expensive as both their production level and use has varied over the last decade.[14] These variations are due, in the most part, to environmental and geo-political considerations, combined with an increased demand for high end electronic goods.[15] Consequently, it is with these factors in mind that new reliable sources of REEs are now being sought. Recent advances in recycling technology as well as the ever decreasing ‘shelf life’ of modern electronic devices have made the idea of device recycling and REEs recuperation a popular one. Also, it should be noted that as the demand for REEs begins to outstrip their production the idea of device recycling begins to be economically viable.[16] However, the separation of mixtures of REEs can prove difficult due to a phenomenon known as lanthanide contraction. This property causes a relatively gradual decrease in ionic size with increasing atomic number giving the various REEs similar sizes and therefore making them difficult to separate. Therefore, This journal is © The Royal Society of Chemistry [year] 60 65 70 75 80 85 with this in mind we present a clean, simple, aqueous route to REE separation using a silica-phosphonate functionalised TiO2 mesoparticle system. Although SiO2 is a more common support for silicaphosphonates, TiO2 will be used as the support of choice in this work.[11, 17-19] TiO2 was chosen due to its resistance to the harsh conditions normally associated with REE extraction, i.e. strong acids and bases. Also unlike silica, TiO2 is not solubilised by concentrated NaOH. This property proved to be important later in this work as NaOH was used to activate the functional groups. TiO2 is amphoteric; this property has been well reported in the literature, as has its use to control the up-take/release of ions from solution.[20-26] Moreover, TiO2 is used as an inorganic support in flow/filtration processes. Therefore, these TiO2 particles simulate can also be used to simulate a membrane support system. The TiO2 particles used in this work were prepared as described in the literature.[27, 28] The prepared particles were found by SEM to be around 360nm in size, slightly soluble in water, and (after a hydrothermal treatment) mesoporous. The Ti precursor and silano-phosphonate functionalising molecule were mixed before the TiO2 particles were co-precipitated to ensure maximum surface coverage. The phosphonate chosen for this work was dimethylphosphatoethyltriethoxysilane (SiP). Normally, when grafting a silane group containing molecule such as SiP the presence of a silica support is preferred. This is done to increase the likelihood that the silica-phosphonate molecule will attach at the silane end, leaving the phosphonate head group free. Therefore, not only does no such guarantee exists here but, it has been well reported in the literature that phosphonate group containing molecules co-ordinate onto the lewis acid site containing Titania surface via the phosphonate oxygen.[29] However, the difficulty with which the SiP phosphonates’ P-O-R groups are hydrolysed as well the relative ease which ethoxy silane groups are hydrolysed are also both well recorded in the literature. Therefore, it is hoped that the methyl groups present around the phosphonate head will offer a certain degree of protection during the TiO2 preparation stage of this work. These – O-CH3 groups will then later be hydrolysed to –O-H (SiP-TiO2; AH) and then –O-Na groups (SiP-TiO2; ANa) using a hydrothermal process and a NaOH(aq) treatment respectively. BET was used to confirm the porous nature of the SiP-TiO2 [journal], [year], [vol], 00–00 | 1 5 10 (AH), while NMR and FT-IR were used to confirm the presence of the SiP on the SiP-TiO2 at various points in its preparation. The sorbants used in this study were all nitrates with the exception of GdCl3. This salt was used to determine the effect, if any, of changing the counter-ion on the absorbance rate of Gd3+ onto the modified SiP-TiO2 particles. In total four REEs nitrates were examined Ce, Nd, Gd and Yb with the focus been placed on Ce and the effect, if any, of the present of the other REEs on Ce sorbance. The effects of the presence of M+ and M2+ on Ce3+ sorbance were also studied. 2. Experimental 60 Note: Unfunctionalised TiO2 was prepared exactly as described in the literature and section 2.2, [27] the only difference being the lack of SiP. 65 2.3. Sorption Experiments 70 2.1. Materials 15 20 25 Dimethylphosphatoethyltriethoxysilane (SiP) was provided by our industrial partners Specific Polymers. Ethylene Glycol (HOCH2CH2OH) and Titanium (IV) Isopropoxide (Ti(OC(CH3)2)4) were obtained from Sigma-Aldrich. All metal nitrates with the exception of Yb(NO3)3.xH2O (Fulka) were also purchased from Sigma-Aldrich. All these materials were used as received. As AES-ICP was the main workhorse tool in determining metal concentration all nitrate stock solutions were prepared to have a metal concentration of ≤ 20 ppm, (mg/L). Millipore water was prepared in house using a Sartorius water system (18.2 MΩ.cm). 75 80 85 2.2. Preparation of SiP functionalised TiO2 30 35 40 45 50 55 The functionalised TiO2 was prepared using a previously reported method which has been slightly modified to include the SiP functionalising molecule.[27] Briefly, 5g of Ti(OCH(CH3)2)4 and 0.8g of SiP were weighed out and mixed well together. This mixture was then poured into 50g of ethylene glycol under constant stirring. The solution turned a deep milk white immediately on addition of the Ti:SiP mixture. The resulting milk white solution was left stirring overnight after which the white colour disappeared and the solution was once again clear and colourless. The Ti:SiP ethylene glycol solution was then poured into 250 ml of acetone under constant stirring. The white colour reappeared and deepened over time. After 2 hours of constant stirring at room temperature the SiPTiO2 dispersion was heated to 60 0C and left to stir for 48 hours. The particles were collected by centrifugation and washed several times with ethanol. They were then dried overnight in an oven at 60 0C and the resulting powder was washed in a soxhlet, where hot ethanol was the solvent, for 24 hours and once again dried overnight in an oven at 60 0C, (After soxhlet, AS). The dried AS particles were then transferred to a 500 ml RBF and 350 ml of Millipore water was added. The contents were sonicated till the particles were well dispersed and then under vigorous stirring were heated to 120 0C for 6 hours. The particles were then collected by decanting and centrifugation, washed several times in millipore water and again oven dried at 60 0C, (After Hydrothermal, AH). The particles were then dispersed in 150 ml of NaOH(aq) (15 g/L) and stirred for an hour. They were collected 2 | Journal Name, [year], [vol], 00–00 by centrifugation and washed with millipore water until neutral. The particles were again dried at 60 0C over night, (After Na treatment, Ana). 90 All sorption studies were carried out in Millipore water. For the kinetic experiments 100 ml of ~20 ppm solutions of the target metals were prepared under constant stirring. Separately, 20 mg of SiP-TiO2 or TiO2 were sonicated in 20 ml of millipore water until a homogeneous dispersion was acquired. To start the kinetic experiment these 20 ml Titania dispersions were added to the 100 ml metal nitrate solutions with the clock starting immediately on addition. 7ml samples were taken at various intervals and immediately passed through a Whatman® 200 nm syringe filter to remove the TiO2 effectively stopping the reaction. The remaining concentration of metal in the filtered solution was then determined using AES-ICP. The Langmuir isotherms were carried out using the same stock solution concentration as described above; 20 ppm of metal. Each isotherm contained 10 points/experiments with each point being a different dilution of the stock solution starting with 2 ppm of metal and the final point being the stock solution itself. Each point consisted of 20 ml of solution/dilution with 4 mg of sorbent. The dispersion were sonicated for 30 minutes to ensure a homogeneous dispersion and then stirred for 20 hours. Again Whatman® 200nm syringe filters were used to stop the sorption process and the remaining metal concentration in solution was determined using ICP-AES. 2.4. Analytical Techniques 95 100 105 110 The morphology of the sample was observed with an ESEM-FIG (FEI Quanta 200). The N2 sorption-desorption isotherm was measured at -196 0C using a micromeritics ASAP 2020 Surface Area and Porosity Analyser. The sample was degassed at 180 0C overnight. The surface area was calculated by the BrunauerEmmett-Teller (BET) method. The pore size was calculated from the maximum of the pore size distribution curve calculated by the Barrett-Joyner-Halenda (BJH) method using the sorption branch of the isotherm. The total pore volume was calculated by the single point method. 13C and 31P and 29Si CP/MAS NMR were measured on a Bruker 400 MHz NMR at 100 Mhz and a sample spinning frequency of 12 KHz. FT-IR scans were performed using a Perkin Elmer Spectrum 100 FT-IR spectrometer. Metal concentration, with the exceptions of sodium and caesium was determined using a Spectro Arcos ICP-OES spectrometer. Cs and Na concentration were determined using an ionic chromatograph. 3. Results and Discussion 3.1 Characterisation of SiP-TiO2 115 This journal is © The Royal Society of Chemistry [year] A. B. C. 5 10 P=O 1244cm-1 15 D. 20 25 30 35 40 45 50 P=O-Ti 1047cm-1 E. Fig. 1 Characterisation of SiP-TiO2; above, ESEM images of SiP-TiO2 before (A) and after (B, C) the hydrothermal treatment. Below left; FT-IR of Dimethylphosphatoethyltriethoxysilane (SiP-black) and SiP-TiO2 (red). Below right; N2 sorption-desorption isotherm with pore size distribution inset. Figure 1 shows the FT-IR spectrum of both SiP-TiO2 (red) and the SiP molecule itself (black), the N2 sortion-desorption isotherm of the SiP-TiO2 after hydrothermal treatment and ESEM of the material both before and after hydrothermal treatment. ESEM indicates that particles are smooth surfaced and spherical with a size distribution of 366 nm ± 57 nm before hydrothermal treatment, (Figure 1A). Once they are subjected to the hydrothermal treatment (6 hours at 110 0C) they retain their shape to a large degree, however, the surface becomes visibly rougher, (Figure 1B & 1C). The size and size distribution also changes slightly after the hydrothermal treatment to 399 nm ± 52 nm. The N2 sorption-desorption isotherm which was carried out on the hydro-thermally treated SiP-TiO2 resulted in a type IV Isotherm with a H1/H4 hysteresis loop, indicating a mesoporous solid, (Figure 1D).[32] While the type IV isotherm is characteristic of capillary condensation taking place in a therefore mesoporous solid, the hysteresis loop itself exhibits aspects of both a H1 and H4 loop. This indicates that while individual particles are mesoporous they are also aggregated. This aggregation effect was also confirmed by the ESEM images, (Figure 1B). FT-IR of the SiP molecule (black spectrum) shows Si-O-Si bending as well as asymmetric and symmetric stretches at 1061,791 and 457 cm-1. PO-C asymmetric stretches can be seen at 1028 cm-1 and 952cm-1 while the P=O signal is present at 1244 cm-1 CH3 deformations are at 1480cm-1 and 1394cm-1 while the C-O signals arising from the silane ethoxy groups are present at 1169 cm-1 and 1076 cm-1, (Figure 1E). After functionalisation (red spectrum) the P-O-C stretch has shifted to 1171 cm-1 while the P=O signal can now be seen at 1276 cm-1, (Figure 1E). The signal at 1428 cm-1 was assigned to P-C stretching vibrations. The peak at 1047 cm-1 This journal is © The Royal Society of Chemistry [year] 55 60 65 70 75 80 although in a region overlapped by the C-O stretches of ethylene glycol and Si-O-Si stretches of intermolecular SiP bonds could very well be due to the presence of P=O...Ti bonds. However, when taking this possibility into account the continued presence of the P=O stretch at 1276 cm-1 as well as the position of the P31 MAS-NMR peaks must also be noted, indicating that there are still free P=O groups present. Although it should be also noted that as this molecule is capable of forming intermolecular bonds via its silane groups it is entirely possible that a “multi-layer” system of SiP is present on the TiO2 surface; with one phosphonate group anchoring the bilayer on the TiO2 surface and the “other” phosphonate group pointing away from the substrate. Finally, the FT-IR peak at 1630 cm-1 was assigned to bound surface water. 13 C, 31P and 29Si MAS-NMR were also used to confirm the presence of the SiP molecule on the TiO2 surface, (Figure 2 and supporting info). 13C MAS NMR (as well as FT-IR) of the SiPTiO2 after the both the soxhlet (AS) and hydrothermal (AH) processes confirm that while the soxhlet has very little effect on the concentration of surface bound ethylene glycol the hydrothermal treatment removes it completely (Supporting info). 13C MAS NMR of the SiP-TiO (AS) shows the presence of the 2 SiP molecule, with characteristic peaks at 7, 20 and 50 ppm, (Figure 2A). While 13C NMR scans of the SiP-TiO2 (AH) and (ANa) still show the presence of the P-O-CH3 peak at 50-51 ppm its relative intensity is now half of what it was in the SiP-TiO2 (AS), (Supporting Info). Although peak integration in 13C MAS NMR is not as precise as in 1H NMR, the now equal intensities of the peaks at 7ppm and 20 ppm which correspond to only one C apiece and the peak at 50 ppm which corresponds to the two Journal Name, [year], [vol], 00–00 | 3 series of complex overlapping signals between 35 ppm and 70 O O P C. 30 ppm 24.15% A. 50 ppm 5 ppm. 40 ppm 75.84% O H 5 ppm O O 20 ppm Si O O O 10 Ti O O P OH Ti O Ti Ti O Si O O O Ti O Ti O 15 H O H O D. 30 ppm 70.75% B. O O O P P O O 40 ppm 29.24% O P O H O O P O Si O Si O Si Ti O O 20 O O Ti O Si O O O Ti O TiO2 25 X 30 35 40 45 Fig 2. (A) & (B) 13C and 29Si MAS NMR of SiP-TiO2 (AH). Structural inset in (A) shows the positions of the assigned carbons while the inset in (B) shows one of several possible forms of attachment to the TiO2 surface. (C) & (D) 31P MAS NMR of SiP-TiO2 (AS) and (AH), respectively. Structure insets show theSiP-TiO2 before and after hydrolysation. Once hydrolysation was taken place the P-OH groups can go on to form bonds with the surface Ti-OH groups. methyl-carbons would seem to indicate that around half of the PO-CH3 groups have been hydrolysed to P-OH groups, (Figure 2C & 2D). 29Si MAS NMR of the SiP-TiO2 (AH) and (ANa) shows a series of complex overlapping signals between 35 ppm and 70 ppm. These include the Ti-O-Si peaks at -41 ppm and -45ppm as well as several doublets (JP-Si = 36.5 Hz) representing the SiP surface molecule in various states of cross-linkage, (Table I). Considering the high degree of intermolecular reactively seen in silanes and that very similar 29Si MAS NMR data to this has been previously presented in the literature for the ethyl analogue of SiP these results were expected. Finally as reported by Pan et al. for acidified SiP-SBA15 the 31P MAS NMR shows two signals (41 ppm and 31 ppm; peak height ration 1:3.14 respectively) close to the position of the original SiP phosphonate peak. [Liquid 31P 4 | Journal Name, [year], [vol], 00–00 50 55 60 NMR on the SiP molecule in CDCl3 showed the phosphonate peak to be at 36 ppm, (supporting info).] The second peak is due to the partially hydrolysed phosphonate forming surface bonds with the TiO2. 31P MAS NMR of the SiP-TiO2 before and after the hydrothermal treatment showed a stark reversal in the intensities of the two peaks. Once the particles were treated in the boiling water the peak at ~ 30 ppm replaced the peak at 40 ppm as the dominate peak, (1:2). As reported by Pan et al. this is due to the continual hydrolysation of the P-OH groups, which then go to form hydrogen bonds with the surface Ti-OH groups. The NaOH treatment seems to further enhance this effect as it continues to hydrolysis the SiPs P-O-CH3 to P-OH groups. His can be seen by the continued increase in the relative height of the 31P MAS NMR peak at 31 ppm, (supporting info). This journal is © The Royal Society of Chemistry [year] Table I 39Si MAS NMR peak assignments for monomeric and oligomeric species obtained from the hydrolysis of SiP. O- represent oxygen’s which are bonded to the TiO2 surface. a Formula δ ppm RSi(OEt)3 RSi(O-)3 R(O-)2SiOSi(O-)¬2R R(O-)2SiOSi(O-)ROSi(O-)2R -47.4 -42.4 -51.3 -60.4 Cerium Sorption Studies-Kinetics 55 60 Cardenas et al. 5 65 3.2 Sorption Studies 10 15 20 25 30 35 40 45 50 Initial tests were carried out using Ce(NO3)3.6H2O on both SiPTiO2, and unfunctionalised TiO2. By comparing functionalised and unfunctionalised TiO2 it was possible to see, firstly, if TiO2 itself had any affinity for Ce3+ while, secondly, observing the ability of the SiP molecule to sorb Ce3+ ions. Surprisingly however, it was found that the difference between the unfunctionalised and SiP-TiO2 (AH) was negligible. The unfunctionalised TiO2 sorbed 22 mg of Ce per gram of TiO2 while the SiP-TiO2 was only slightly above this at 29 mg/g. These results were found to be almost identical when compared to those observed for Ce3+ sorbed onto both plain and SiP functionalised SBA-15 (literature standard) when the results were normalised for molar mass, (supporting info). ). It should be also noted that a batch of SiP-TiO2 (AH) particles were also boiled in 12M HCl as is recommended in the literature, however, this seemed to diminish, not enhance, its metal sorption properties. However, unlike SBA-15, TiO2 is not solubilised by strong bases and therefore it was possible to treat the SiP-TiO2 (AH) particles with concentrated NaOH(aq). That is to carry out a base (and not acid) hydrolysis of any remaining P-O-CH3 groups. Briefly, SiP functionalised mesoporous TiO2 (AH) was treated with concentrated NaOH(aq), (15g/L) and washed till neutral. These SiP-TiO2 (ANa) particles were then used as the sorbent throughout these studies. The supporting information shows four Ce3+ absorption isotherms representing functionalised and unfunctionalised TiO2, which were both treated, and not treated, with NaOH(aq). While the NaOH wash has little effect on the unfunctionalised TiO2 it increases the sorption ability of the functionalised SiP-TiO2 by a factor of 3. The enhancement of the SiP-TiO2 (ANa) particles ability to sorb Ce3+ after the NaOH wash is due to firstly, a base hydrolysis of any remaining surface P-O-CH3 groups and secondly the replacement of any Ti-OH and P-OH groups with Ti-ONa and P-ONa groups. As mentioned earlier in this section SiP-TiO2 (AH) sorption of cerium is almost identical to that of acidified SiP-SBA-15, therefore we believe the increased affinity of the SiP-TiO2 (ANa) for Ce3+ (and other metals) is more a result of the greater ease with which Ce3+ can be exchanged for Na+ over H+ than an increase in the number of available P-OH sites. The relatively small change in the intensities of the 31P MAS NMR peaks before and after the NAOH treatment also suggests that the number of hydrolysed phosphonate groups remains to a large extent unchanged (Supporting Info). Ionic chromatography was used to confirm that equimolar amounts of Na+ were released as other metals Cs+, Sr2+ and Ce3+ were sorbed by the SiP-TiO2 (ANa). This journal is © The Royal Society of Chemistry [year] 70 75 80 85 90 95 100 105 110 Initial separation studies with the NaOH washed SiP-TiO2 (ANa) particles were carried out to determine if Ce3+ could be separated from a solution of di- and monovalent metals. The industrially significant elements strontium and caesium were chosen as the M2+ and M+ metals respectively. In the case of the kinetic experiments 20 mg of functionalised TiO2 were sonicated in 20ml of millipore for 30 minutes or until completely dispersed. This dispersion was then added to a 100ml combined solution of the three metal nitrates (≥ 20 mg/l each) in millipore water. Samples were taken at set intervals over a 6 hour period and filtered using 200nm Whatman® hydrophilic filters to remove the SiP-TiO2. It should be noted that 50% of total cerium sorbtion is done so in the first five minutes, (Figure 3a). Although Sr2+ is also initially sorbed within the first five minutes this is quickly reversed and the metal is released. Therefore, from these results we see that the ligand is not actually charge specific in that it does not selectively bind M+3 ions over M+2. However, in this high concentration, competitive environment previously sorbed Sr+2 ions are quickly released to accommodate any Ce3+ ions present in solution; this is also true for Cs+1 ions which are sorbed in the early stages of the process, (Figure 3b). This metal exchange also demonstrates the SiP molecules’ ability to easily desorb as well as sorb metal ions. Cerium Sorption Studies-Langmuir Isotherms Figure 3b shows an adsorption isotherm plot of the same system with the Caesium and Sodium data now included. Each point on the Langmuir curve represents a different experiment. Each point/experiment involved the stirring overnight of 4 mg of well sonicated SiP-TiO2 (ANa) in metal nitrate solutions of ever increasing concentrations. At low concentrations the particles sorb all three metals indiscriminately. However, as the concentrations of the metals are increased a point is reached where only the Ce3+ is sorbed. That is to say it is preferentially sorbed over the others. This point was also equilibrium concentration, at which the SiP-TiO2 has sorbed all the metal it can. Measurement of the equilibrium Na+ concentration in each point of the adsorption isotherm showed an increase in the sodium concentration as the initial metal nitrate concentrations were increased, until it eventually plateaus at 40mg/g, (Figure 3b). Ionic chromatography of the metal nitrate stock solutions showed the presence of negligible amounts of Na+; therefore the SiP-TiO2 particles are the only source of Na+ ions in these isotherms. The Na+ concentration released is dependent on the concentration of Mn+ sorbed by the SiP-TiO2 (ANa) particles. This clearly demonstrates that an ion exchange is indeed taking place. Also, if the amounts of Ce3+, Sr2+ and Cs+ sorbed by the SiP-TiO2 are converted to millimoles and multiplied by their corresponding charge, i.e. millimoles of charge, the obtained number is almost equal to the concentration of Na+ released, (Table II). When the sodium concentration eventually plateaus indicating all sodium has been released (20mg/L, Figure 3b) it is then the previously sorbed Sr2+ and Cs+ that act as the ion exchangers allowing more Ce3+ to be taken out of solution as they themselves are released. Journal Name, [year], [vol], 00–00 | 5 sorption process the experimental data was put through both the pseudo-first- and pseudo-second-order kinetic models. The linearized form of the pseudo-first-order rate equation by Lagergren is given below, (equation 1). 100 A. Sorbed Metal Concentration (mg/g) 90 5 10 80 50 70 60 (qe - qt) = qeexp( – k1t) 50 (1) 40 55 30 20 10 0 -20 30 80 130 180 230 60 Time (minutes) Where k1 is the sorption rate constant (min-1), while qe and qt are the amounts of metal sorbed onto the SiP-TiO2 (ANa) in mg of metal per gram of SiP-TiO2 (ANa) at equilibrium and at time (t) respectively. The plot of (qe - qt) versus t gives a straight line and k1 can be calculated by finding the slope. The pseudo-secondorder kinetic model is given with the equation. 100 90 B. 80 Metal Sorbed (mg/g) 15 65 70 60 30 70 10 0 -10 10 30 50 70 90 110 Metal Concentration (mg/L) 75 Fig 3. A; Effect of stirring time on the sorption of Ce3+ (red) and Sr2+ (blue) onto SiP-TiO2 (ANa). Initial Sr sorbance is reversed within the first 15 minutes. B; Sorption Isotherm of the Ce, (red diamonds), Sr, (blue squares), and Cs, (green/yellow triangles) solution on SiP-TiO2 (ANa). The red x’s represent the Na+ released by the SiP-TiO2 (ANa) as it absorbs the other metals. Table II Millimoles of charge (milliequivalent) of all three studied metals sorbed, or in the case of sodium released, at a specific concentration point in the Isotherm in Fig. 3B. 10ppm 20ppm 70ppm a 1 k2qe2 - t qe (2) 40 20 30 = 50 20 25 t qt Ce3+ Sr2+ Cs+ Total Na+ 0.44 0.855 1.92 0.46 0.9 0 0.2 0.1 0 1.1 1.86 1.92 1.22 1.73 1.73 80 85 90 Footnote text. Both qe and qt have the same meaning as above and k2 is the rate constant, (g/mg/min). A plot of t/qt vs. t is linear, and qe and k2 can be calculated from the slope and intercept respectively. The model parameters and the correlation coefficient obtained for both equations are seen in table III. While both sets of results fit well with high R2 values, the pseudo-second-order kinetic equation has a higher R2 value and its qe value is closer to that which was observed experimentally. As was pointed out in the previous section this system behaves as a chelating exchanger, releasing the previously sorbed Na+ for the metals in solution. Therefore, it is no surprise that second-order-kinetics can be applied here. Of course the support itself must also be considered. The sorption process on porous solids can be broken down into four different stages i). bulk diffusion, ii). film diffusion, iii). intraparticle diffusion and iv). sorption (or ionic exchange) of the adsorbate on the surface. As one or more of these processes are diffusion limited steps, which diffusion steps are limited they may determine the rate and amount of material sorbed they must also be investigated. As the SiP-TiO2 has a porous structure, further investigation was carried out to determine which diffusion steps are limited to the entire sorption process. Then the diffusion model is expressed using the Weber and Morris equation below. 32 35 95 qt = kidt1/2 (3) Kinetic Model 40 45 The sorption rate of Ce3+ on SiP-TiO2 (ANa) was studied with an initial (T=0) Ce3+ concentration of 225mg/g over a 3 hour period. As was seen in figure 3a the kinetics are very fast especially in the first five minutes, where 50% of the total Ce3+ metal sorbed is taken-up. However, it takes over 3 hours for equilibrium to be reached. This equilibrium time is slower than reported for ethyl analogue on SBA-15 and U(IV).17 To create a clearer picture of the 6 | Journal Name, [year], [vol], 00–00 100 As before qt is the amount of metal sorbed at time t in mg/g. The constant kid is the diffusion constant (mg/g/h). A plot of qt as a function of t1/2 gives a straight line from which kid can be found. The experimental kinetic data was applied to equation (3), as shown in Figure 10. The points are not linearly distributed but give four straight lines with four different slopes. Similar kinetics This journal is © The Royal Society of Chemistry [year] 55 Table III. Kinetic model constants and correlation coefficients highlighting the sorption of Ce3+ onto SiP-TiO2 (ANa). Exp = experiment result. Pseudo-1st -Order Pseudo-2nd -Order qe (mg/g) k1 (min-1) R2 qe (mg/g) 86.16 3.36 x 10-2 0.997 92.59 Exp. R2 qe (mg/g) 0.998 92 k2 (g/mg/min) 5 a 10 15 20 Footnote text. were observed on the sorption of humic acid by cross-linked chitosan beads and on the sorption of U(VI) by chitosantripolyphosphate beads, and on the sorption of U(VI) on DPTS functionalised SBA-15.17 Specifically, the initial steep-sloped portion represents the bulk diffusion or exterior sorption rate which is very high. The second and third portions can be attributed to intra-particle diffusion in first, the outer “shell” which was created by the hydrothermal process, and second, in the “core” TiO2. Lastly, the fourth portion corresponds to the chemical equilibration of Ce3+ in SiP-TiO2. Such kinetics suggests that intra-particle diffusion may play an important role in the rate determination in the sorption process but not the sole rate determining factor because of the deviation of the curves from the origin and non-linear distribution of the plots. can be expressed according to the equation below, (Equation 4).34 65 100 75 80 y = 2.484x + 55.508 R2 = 0.9998 3rd 90 80 Ce qe 70 25 30 9.84 x 10-4 60 y = 0.0963x + 87.608 R2 = 1 4th + 1 (4) Qb Ce is the equilibrium concentration of adsorbate (mg/L), qe represents the amount of adsorbed adsorbate at equilibrium (mg/g), and Q and b are the Langmuir constants related to sorption capacity (mg/g) and the affinity of the binding sites on sorbent (ml/mg), respectively, (Equation 4). Q and b can be obtained by plotting Ce/qe versus Ce. Table IV lists the parameters of the Langmuir model for the Ce3+ sorption on SiPTiO2 (ANa). Table IV. Cerium Isotherm model constants and coefficients. 70 Q (mg/g) B (ml/mg) 60 y = 5.2755x + 33.216 R2 = 0.9918 2nd t 50 q Ce Q = 92.59 40 a 30 12 R2 Exp. (mg/g) 0.9998 92.98 ΔGL (J/mol) -17309 Footnote text. 85 y = 20.707x - 6E-15 R2 = 1 1st 20 35 10 0 -2 3 8 13 18 t0.5 90 Fig 4. Particle diffusion model kinetics of Ce3+ sorbed onto SiP-TiO2 (ANa) particles. 40 95 From the good correlation coefficient of 0.9998 and the fact that the equilibrium sorption capacity (Q) obtained from Langmuir model (92.59 mg/g) is practically identical to the experimentally observed saturation capacity (92.98 mg/g), it can be concluded that the sorption of Ce3+ onto SiP-TiO2 follows the Langmuir sorption model. According to the Langmuir model, the favourability of SiP-TiO2 (ANa) as a Ce3+ sorbent, related to the separation factor RL, can be obtained from the Langmuir sorption constant, equation 5, where C0 is the initial metal ion concentration. Sorption Isotherm Model 45 50 Adsorption isotherms are fundamental to the understanding of the sorption mode of an adsorbate on sorbent surface when equilibrium is attained. Therefore, as shown earlier (Figure 3b), a sorption isotherm was determined by studying the amount of Cerium adsorbed onto the SiP-TiO2 (ANa) as a function of metal concentration in the supernatant at equilibrium (Ce) at near neutral conditions. The Langmuir isotherm model usually used to fit the experimental data is based on the assumption that the metal ions are sorbed as a monolayer, uniform and finite. Also it is assumed that the sorption energy decreases as the distance from the surface increases. The linear form of the Langmuir isotherm This journal is © The Royal Society of Chemistry [year] RL = 1 1 + bC0 (5) 100 105 0 < RL < 1 designates that the sorbent is a favourable medium for the sorption of the given metal ion. The calculated RL values were found to be between 8.6 x 10-3 to 9.3 x 10-4. Since these values are between 0 and 1, the SiP-TiO2 (ANa) can be considered a favourable sorbent for Ce3+. The ΔGL, the affinity of the SiP ligand for Ce3+, was also calculated from this data and was found to be -17309 J/mol. Journal Name, [year], [vol], 00–00 | 7 Lanthanide Separation 5 10 15 20 55 The ability of SiP-TiO2 (ANa) to separate Ce3+ from other L3+ ions was also examined. Nitrates of Nd (III), Gd (III), and Yb (III) were chosen for these studies due to a). their M3+ charge and b). their every increasing atomic mass. Briefly, millipore water solutions of Ce3+ and the other lanthanide to be examined were prepared. To these stock solutions (Ce/Nd, Ce/Gd and Ce/Yb) was then added the SiP-TiO2 (ANa) using the same procedure which was described for the earlier kinetic experiments. The results of these experiments are presented in table V. Again, the most striking thing about these results is the amount of metal sorbed within the first 5 minutes. The Ce3+ and Nd3+ mixture shows almost identical equilibrium concentrations for both metals. This is not surprising as Ce3+ and Nd3+ have very similar atomic radii and molar masses. However, the Ce3+/Gd3+ and Ce3+/Yb3+ mixtures do show some degree of separation. As the molecular weight of the competitor lanthanide increases so too does its uptake. These results are highlighted in Table V below, which shows the equilibrium points of these experiments in millimoles of metal per gram of SiP-TiO2 (ANa), as well as the ratio of M3+ to Ce3+. 60 counter-ion a solution of Gd and Sr chloride was prepared. This was then stirred with SiP-TiO2 (ANa) (as in previous experiments) and the results were examined. Again, no Sr2+ was still sorbed by the time the equilibrium point was reached. The use of either GdCl3 or Gd(NO3)3 as the Gd source made very little difference to the overall shape of the sorbance curve. The equilibrium concentration of Gd was slightly higher when GdCl3 was used as the Gd source; (Gd(NO3)3 0.744 mm/g vs. GdCl3 0.795mm/g, however, this difference is well within the bounds of experiment error. Therefore, the type of counter-ion used seems to have little effect on the sorption process in these experimental conditions. 65 Table VI. Gadolinium Isotherm model constants and coefficients. Q (mg/g) B (ml/mg) R2 Exp. (mg/g) ΔGL (J/mol) 120.48 a 41.49 0.9996 121.17 -21022 Footnote text. 70 Table VII. Ytterbium Isotherm model constants and coefficients. Q (mg/g) B (ml/mg) 138.8 360 R2 Exp. (mg/g) ΔGL (J/mol) 25 Table V. Equilibrium concentrations of Ce/Nd, Ce/Gd and Ce/Yb solutions sorbed onto SiP-TiO2 (ANa) in millimole metal sorbed per gram of SiP-TiO2. Ratio of Ce3+ to M3+ sorbed is also shown. Ce (mmol/g) Nd (mmol/g) Gd (mmol/g) 0.428 0.495 0.335 a Yb (mmol/g) Ratio 0.479 1: 1.02 1: 1.325 1: 1.429 0.44 0.656 a 75 30 80 35 40 45 50 138.01 -26705 Footnote text. Conclusions Footnote text. As mentioned above the ratio of Ce/Nd sorbed is almost 1:1 while 32.5% more Gd3+ and 42.9% more Yb3+ are sorbed than Ce3+ in their respective experiments. This seems to suggest that as the difference in weight between the metal ions increases so too does the ability of the SiP-TiO2 (ANa) to separate them, with the sorbent preferring heavier lanthanides. Langmuir adsorption isotherms were also individually carried out on Gd(NO3)3 and Yb(NO3)3. These were performed by repeating the experiment described earlier, (Figure 3b), but replacing the Ce with Gd or Yb. The results are tabled below. By comparing tables IV, VI and VII we see that there is an increase in both the Langmuir constants (Q and b) and the absolute ΔGL values for SiP-TiO2 (ANa) as the MW of the target lanthanide is increased. This indicates that SiP-TiO2 (ANa) shows a higher affinity for Gd, than Yb than Ce. We therefore submit that this material could be used to separate Lanthanides depending on whether they are light Ln as opposed to heavy Ln. 0.9997 85 90 95 A novel sorbent composed of phosphonate functionalised mesoporous titania was synthesised by the co-condensation method and used in Ln3+ sorption, in batch processes. The sorption of Ln3+ on SiP-TiO2 (ANa) was studied as a function of various parameters such as time, pH, and Ln 3+ concentration. The initial kinetics of Ln3+ sorption on SiP-TiO2 (ANa) is ultra-fast with 50% of total metal sorbed being done so with in the first minute or two. However, equilibrium time is over 3 hours. The sorption of Ce3+ was found to follow pseudo-second-order type sorption kinetics. Intraparticle diffusion plays an important role in the sorption processes but it could not be accepted as the sole rate-determining step. The measured maximum sorption capacity depends on the metal examined starting with Ce at 92 mg/g and increasing with the molecular weight of the lanthanide. The sorption isotherms for Ce3+, Gd3+ and Yb3+ have been successfully modelled by the Langmuir isotherm which revealed a monolayer chemical sorption. The sodium washed SiP functionalised TiO2 demonstrated some ability to separate Ln3+ metals according to molecular mass. Finally, it was noted that changing of the counter-ion from nitrate to chloride had little effect on the shape or equilibrium concentration of the sorption of Gd3+. Counter-ion tests To investigate the effect on SiP-TiO2 (ANa) of changing the 8 | Journal Name, [year], [vol], 00–00 This journal is © The Royal Society of Chemistry [year] Notes and references a 5 10 Address, Address, Town, Country. Fax: XX XXXX XXXX; Tel: XX XXXX XXXX; E-mail: xxxx@aaa.bbb.ccc b Address, Address, Town, Country. Fax: XX XXXX XXXX; Tel: XX XXXX XXXX; E-mail: xxxx@aaa.bbb.ccc † Electronic Supplementary Information (ESI) available: [details of any supplementary information available should be included here]. See DOI: 10.1039/b000000x/ ‡ Footnotes should appear here. These might include comments relevant to but not central to the matter under discussion, limited experimental and spectral data, and crystallographic data. 1 A. Name, B. Name and C. Name, Journal Title, 2000, 35, 3523; A. Name, B. Name and C. Name, Journal Title, 2000, 35, 3523. 75 80 85 15 1. 20 2. 3. 25 4. 5. 30 6. 7. 35 8. 40 9. 45 10. 11. 50 12. 13. 55 14. 15. 60 16. 17. 65 18. 19. 70 Jones, A.C., H.C. Aspinall, and P.R. Chalker, Molecular design of improved precursors for the MOCVD of oxides used in microelectronics. Surface and Coatings Technology, 2007. 201(22– 23): p. 9046-9054. Murthy, Z.V.P. and A. Choudhary, Separation of cerium from feed solution by nanofiltration. Desalination, 2011. 279(1–3): p. 428-432. Chaudhury, K., et al., Mitigation of endometriosis using regenerative cerium oxide nanoparticles. Nanomedicine: Nanotechnology, Biology and Medicine, (0). Eski, M., et al., Cerium nitrate treatment prevents progressive tissue necrosis in the zone of stasis following burn. Burns, 2012. 38(2): p. 283-289. Christoffers, J., T. Werner, and M. Rössle, Cerium-catalyzed oxidative C–C bond forming reactions. Catalysis Today, 2007. 121(1–2): p. 22-26. Maestro, P. and D. Huguenin, Industrial applications of rare earths: which way for the end of the century. Journal of Alloys and Compounds, 1995. 225(1–2): p. 520-528. Zhang, L., et al., Facile one-pot sonochemical synthesis of hydrophilic ultrasmall LaF3:Ce,Tb nanoparticles with green luminescence. Progress in Natural Science: Materials International, 2012. 22(5): p. 488-492. Hasannejad, H., T. Shahrabi, and M. Jafarian, Synthesis and properties of high corrosion resistant Ni–cerium oxide nanocomposite coating. Materials and Corrosion, 2012: p. n/a-n/a. Zheng, X.-L., et al., Bright Blue-Emitting Ce3+ Complexes with Encapsulating Polybenzimidazole Tripodal Ligands as Potential Electroluminescent Devices. Angewandte Chemie International Edition, 2007. 46(39): p. 7399-7403. Xiao, Z., et al., Up-conversion luminescence from neodymium ion implantation silicon. Surface and Coatings Technology, 2000. 128– 129(0): p. 461-464. Melnyk, I.V., et al., Sorption properties of porous spray-dried microspheres functionalized by phosphonic acid groups. Microporous and Mesoporous Materials, 2012. 153(0): p. 171-177. Leung, P.K., et al., Characterization of a zinc–cerium flow battery. Journal of Power Sources, 2011. 196(11): p. 5174-5185. Various, Catalysis by Ceria and Related Materials, ed. A. Trovarelli. 2002: Imperial College Press. Hammond, C.R., ed. The Elements, in Handbook of Chemistry and Physics 81st edition. 2000, CRC Press. Laila Manji, G.M., Carl Firman, ABN AMRO Geopolitical Analysis Rare earth elements – risk analysis, in Geopolitical Analysis Quarterly. 2011, VM Group: London. TABUCHI, H., Japan Recycles Minerals From Used Electronics, in New York Times. 2010, New York Times: New York. Yuan, L.-Y., et al., High performance of phosphonate-functionalized mesoporous silica for U(vi) sorption from aqueous solution. Dalton Transactions, 2011. 40(28): p. 7446-7453. Dudarko, O.A., et al., Sorption of Hg2+, Nd3+, Dy3+, and UO22+ ions at polysiloxane xerogels functionalized with phosphonic acid derivatives. Protection of Metals, 2008. 44(2): p. 193-197. Yong Gang, J., et al., Phosphonic acid functionalized silicas for intermediate temperature proton conduction. Journal of Materials Chemistry, 2009. 19(16): p. 2363-72. This journal is © The Royal Society of Chemistry [year] 90 95 100 105 110 20. Dutournié, P., et al., Unsteady transport of divalent salt through a mineral membrane of ultrafiltration: Numerical estimation of physical parameters. Desalination, 2011. 265(1–3): p. 184-189. 21. Kallay, N., D. Babić, and E. Matijević, Adsorption at solid/solution interfaces II. Surface charge and potential of spherical colloidal titania. Colloids and Surfaces, 1986. 19(4): p. 375-386. 22. Comarmond, M.J., et al., Uranium Sorption on Various Forms of Titanium Dioxide - Influence of Surface Area, Surface Charge, and Impurities. Environmental Science & Technology, 2011. 45(13): p. 5536-5542. 23. Panagiotou, G.D., et al., Mapping the surface (hydr)oxo-groups of titanium oxide and its interface with an aqueous solution: The state of the art and a new approach. Advances in Colloid and Interface Science, 2008. 142(1-2): p. 20-42. 24. Engates, K.E. and H.J. Shipley, Adsorption of Pb, Cd, Cu, Zn, and Ni to titanium dioxide nanoparticles: effect of particle size, solid concentration, and exhaustion. Environmental Science and Pollution Research, 2011. 18(3): p. 386-395. 25. Tsuru, T., et al., Effect of divalent cations on permeate volume flux through porous titania membranes. Desalination, 2002. 147(1–3): p. 213-216. 26. Tsuru, T., et al., Titania membranes for liquid phase separation: effect of surface charge on flux. Separation and Purification Technology, 2001. 25(1–3): p. 307-314. 27. Li, S., et al., Simple preparation of sub-micron mesoporous TiO2 spheres consisting of anatase nanocrystals. Journal of Alloys and Compounds, 2010. 508(1): p. 99-105. 28. Jiang, X., T. Herricks, and Y. Xia, Monodispersed Spherical Colloids of Titania: Synthesis, Characterization, and Crystallization. Advanced Materials, 2003. 15(14): p. 1205-1209. 29. Guerrero, G., P.H. Mutin, and A. Vioux, Anchoring of Phosphonate and Phosphinate Coupling Molecules on Titania Particles. Chemistry of Materials, 2001. 13(11): p. 4367-4373. 30. W. Ostwald, Z. Phys. Chem. , 1897. 22 p. 289. 31. Ostwald, W., Z. Phys. Chem., 1900. 34 p. 495. 32. K.S.W Sing, D.H.E., R.A.W Haul, L. Moscou, R.A Pierotti, J. Rouquérol, T. Siemieniewska, Reporting Physisorption Data for Gas/Solid Systems. Pure & Appl. Chem., 1985. 57: p. 603-619. 33. Pan, Y.-C., et al., Probing the Nature and Local Structure of Phosphonic Acid Groups Functionalized in Mesoporous Silica SBA15. The Journal of Physical Chemistry C, 2011. 116(2): p. 16581669. Journal Name, [year], [vol], 00–00 | 9