abstract-template

advertisement

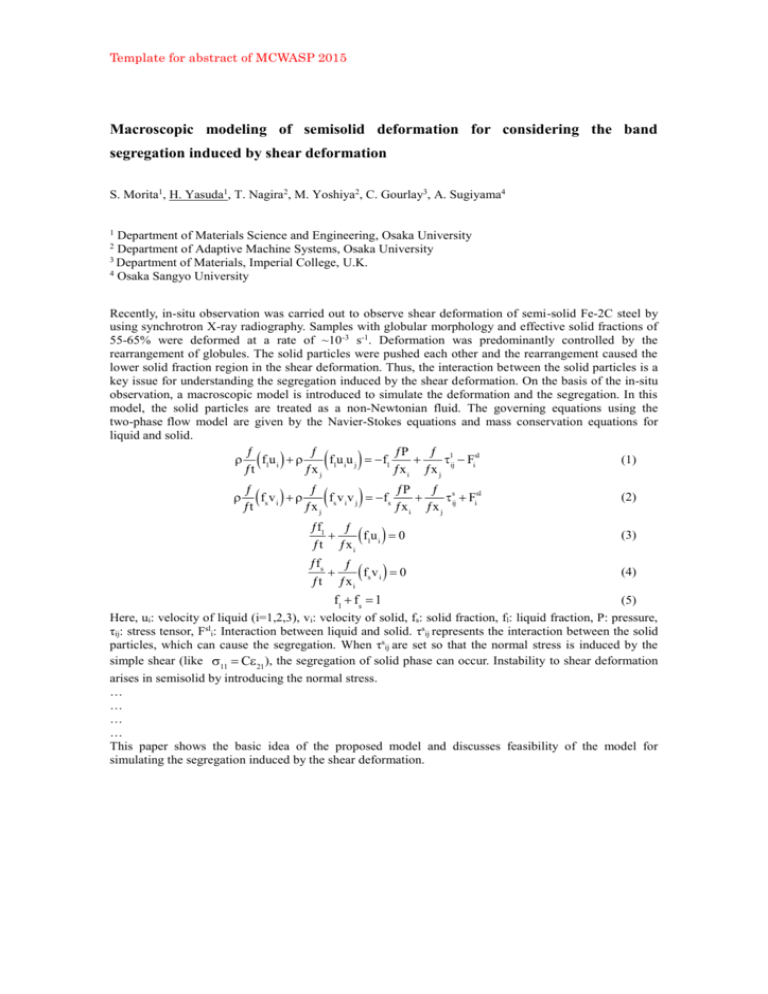

Template for abstract of MCWASP 2015 Macroscopic modeling of semisolid deformation for considering the band segregation induced by shear deformation S. Morita1, H. Yasuda1, T. Nagira2, M. Yoshiya2, C. Gourlay3, A. Sugiyama4 1 Department of Materials Science and Engineering, Osaka University Department of Adaptive Machine Systems, Osaka University 3 Department of Materials, Imperial College, U.K. 4 Osaka Sangyo University 2 Recently, in-situ observation was carried out to observe shear deformation of semi-solid Fe-2C steel by using synchrotron X-ray radiography. Samples with globular morphology and effective solid fractions of 55-65% were deformed at a rate of ~10-3 s-1. Deformation was predominantly controlled by the rearrangement of globules. The solid particles were pushed each other and the rearrangement caused the lower solid fraction region in the shear deformation. Thus, the interaction between the solid particles is a key issue for understanding the segregation induced by the shear deformation. On the basis of the in-situ observation, a macroscopic model is introduced to simulate the deformation and the segregation. In this model, the solid particles are treated as a non-Newtonian fluid. The governing equations using the two-phase flow model are given by the Navier-Stokes equations and mass conservation equations for liquid and solid. ¶ ¶ ¶P ¶ l (1) r flu i + r fl u iu j = -fl + t - Fsl ¶t ¶x j ¶x i ¶x j ij i ( ) r ( ) ( ) (2) ¶fl ¶ + fu =0 ¶t ¶x i l i (3) ¶fs ¶ + f v =0 ¶t ¶x i s i (4) f l + fs = 1 (5) ¶ ¶ ¶P ¶ s fs v i ) + r fs v i v j = -fs + t + Fsl ( ¶t ¶x j ¶x i ¶x j ij i ( ) ( ) Here, ui: velocity of liquid (i=1,2,3), vi: velocity of solid, fs: solid fraction, fl: liquid fraction, P: pressure, τij: stress tensor, Fsli: Interaction between liquid and solid. τsij represents the interaction between the solid particles, which can cause the segregation. When τsij are set so that the normal stress is induced by the simple shear (like s11 = Ce 21 ), the segregation of solid phase can occur. Instability to shear deformation arises in semisolid by introducing the normal stress. … … … … This paper shows the basic idea of the proposed model and discusses feasibility of the model for simulating the segregation induced by the shear deformation. Template for abstract of MCWASP 2015 Information Speaker Hideyuki YASUDA Title Dr. Affiliation Department of Materials Science and Engineering, Kyoto University e-mail yasuda.hideyuki.6s@kyoto-u.ac.jp Tel +81-75-753-3339 Fax +81-75-753-3339 Presentation preference Oral / Poster / Either one will be fine Topics <please choose your preference> 8, 13, 14 <please choose topics from the list. Max 3> Topics 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. Solidification processing of metallic alloys and non-metallic materials. Shape casting (sand casting, HPD casting, thixocasting, rheocasting, lost foam,..), continuous casting. Welding and soldering processes. Treatment after casting (heat treatment, machining, shot peening). Novel process techniques. Green technology in casting, solidification and welding (recycling etc…) Processing / structure / property relations. High temperature/ mushy zone properties. Properties of mold and core materials (thermal conductivity, specific heat, density, mechanical properties). Nucleation, grain refinement, inoculation techniques. Microstructure evolution, columnar-to-equiaxed Transition, globular-to-dendritic transition. Micro- and macrosegregation, thermodynamic of solidification. Stress and deformation, hot tearing, macro-shrinkage, and porosity. In-situ observations of solidification phenomena and comparison with predictions. Numerical techniques for solidification modeling (FEM, FVM, DEM, LB, …) High performance computing, parallelization strategies. Others