Max Altitude - Kristian Patel

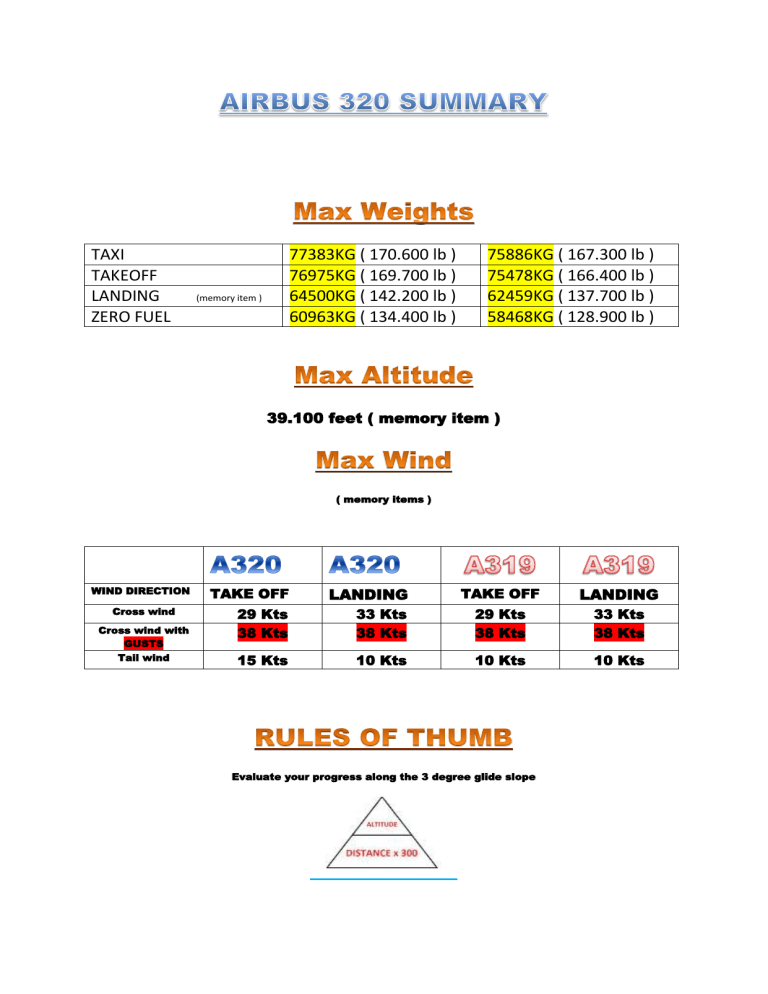

TAXI

ZERO FUEL

77383KG ( 170.600 lb ) 75886KG ( 167.300 lb )

TAKEOFF 76975KG ( 169.700 lb ) 75478KG ( 166.400 lb )

LANDING

(memory item )

64500KG ( 142.200 lb ) 62459KG ( 137.700 lb )

60963KG ( 134.400 lb ) 58468KG ( 128.900 lb )

39.100 feet ( memory item )

( memory items )

WIND DIRECTION

Cross wind

Cross wind with

GUSTS

Tail wind

TAKE OFF

29 Kts

38 Kts

15 Kts

LANDING

33 Kts

38 Kts

10 Kts

TAKE OFF

29 Kts

38 Kts

10 Kts

LANDING

33 Kts

38 Kts

10 Kts

Evaluate your progress along the 3 degree glide slope

IF A PUMP QUITS, IT IS NOT REALLY A BIG DEAL BECAUCE EVERY PUMP

IS BACKED UP BY AN ALTERNATE HYDRAULIC POWER SOURCE

The aircraft has 3 continously operating hydraulic systems: Blue, green and yellow. Each system has its own hydraulic reservoir. Normal system operating pressure is 3000 PSI ( 2500 PSI when powered by the RAT). Hydraulic fluid cannot be transferred from one system to another.

IT IS NOT POSSIBLE TO TRANSFER HYDRAULIC FLUID BETWEEN SYSTEMS.

THEREFORE, IF A SYSTEM LOSES FLUID… SOME SYSTEMS CAN NO LONGER BE OPERATED.

LIST OF THE AFFECTED SYSTEMS:

GREEN

REVERSER # 1

BLUE

THE EMERGENCY

GENERATOR

YELLOW

REVERSER # 2

GEAR RETRACTION

NOSE WEEL STEERING

PARKING BRAKE

ACCUMULATOR

RECHARGING

CARGO DOOR

The NORMAL brake system uses GREEN SYSTEM pressure. That gauge DOES NOT reflect GREEN

SYSTEM or NORMAL BRAKING pressure.

When you depress the RUDDER BRAKES or “ Toe” BRAKES then you are selecting GREEN SYSTEM and the pressure gauge should indicate “ ZERO”.

When you depress the rudder toe brakes, the system shifts to GREEN system. IF you see ANY pressure indicating on the gauge that means that YELLOW system pressure is available to the alternate brakes, then you have a problem!

GREEN SYSTEM PUMP

A pump driven by Engine # 1 pressurizes the green system.

BLUE SYSTEM PUMPS

An electric pump pressurizes the blue system. A pump driven by Ram air turbine (RAT) pressurizes this system in an Emergency.

YELLOW SYSTEM PUMPS

A pump driven by Engine # 2 pressurizes the yellow system. An electric pump can also pressurize the yellow system, which allows hydraulic to be used on ground when engines are stopped.

Crew memembers can also use a hand pump to pressurize the yellow system in order to operate the cargo doors when no electrical power is available.

POWER TRANSFER UNIT ( PTU )

A bidirectional power transfer unit enables the yellow system to pressurize the green system and vice versa. The power transfer unit comes into action automatically when the differential pressure between the green and the yellow systems is greater than 500 PSI. The PTU therefore allows the green system to be pressurized on the ground when the engines are stopped.

RAM AIR TURBINE ( RAT )

A drop-out RAT coupled to a hydraulic pump allows the blue system to function if electrical power is lost or both engines fail. The RAT deploys automatically if AC BUS 1 and AC BUS 2 are both lost. It can deployed manually from the overhead panel. It can be stowed only when the aircraft is on the ground.

SYSTEM ACCUMULATORS

An accumulator in each system helps to maintain a constant pressure by covering transient demands during normal operation.

PRIORITY VALVES

Priority valves cut off hydraulic power to heavy load users if hydraulic pressure in a system gets low.

FIRE SHUTOFF VALVES

Each of the green and yellow systems has a fire shutoff valve in its line upstream of its engine-driven pump. The flight crew can close it by pushing the ENG 1(2) FIRE pushbutton.

GENERAL

THE SYSTEM HAS 6 MAIN FUEL PUMPS.

There are 3 FUEL TANKS

( 7 fuel compartments )

APPROXIMATE REFUELLING TIME AT NOMINAL PRESSURE IS:

17 MIN FOR WING TANKS AND 20 MIN FOR ALL TANKS.

The WING TANK PUMPS are designed to operate continuously.

-

The ORDER for fuel usage is for the CENTER TANK to be used FIRST, then WING

TANKS.

( in order for to do that, the WING TANK pumps are fitted with PRESSURE RELIEF VALVES so the

CENTER TANK PUMPS supply greater pressure. )

TWO ELECTRICAL TRANSFER VALVES ARE MOUNTED IN EACH WING TO

PERMIT FUEL TRANSFER FROM OUTER TO INNER TANK.

FUEL CANNOT BE TRANSFERRED BETWEEN THE 3 TANKS.

( except during normal fueling operations )

THERE IS NO FUEL JETTISON SYSTEM

ENGINES WILL SUCTION FEED, BUT FROM WING TANKS ONLY.

CIRCULATES FUEL TO COOL THE INTERGRATED DRIVE GENERATOR (IDG)

KEEPS FUEL IN THE OUTER WING FOR WING BENDING AND FLUTTER RELIEF.

GENERAL

The electrical power system consists of a Three –phase 115/200 V 400 Hz constans-frequency AC system and a 28 V DC system.

Electrical transients are acceptable for equipment. Commercial supply has secondary priority.

In normal configuration, the electrical power system provides AC power. A part of this AC power is converted into DC power for certain applications. The electrical power system constituted of 2 engine generators and 1 APU generator. Each generator can provide AC power to all electrical bus bars. In the event that normal AC power is not available, and emergency generator can provide AC power. In the event that all AC power is not available, the electrical power system can invert DC power from the batteries into AC power.

AC GENERATORS

ENGINE – DRIVEN GENERATORS

2 three – phase AC generators ( GEN 1, GEN 2 ), one driven by each main engine through an integrated drive, supply aircraft electrical power. Each generator can supply up to 90 KVA of power at

115 and 200 V and 400 Hz.

APU GENERATOR AND EXTERNAL POWER

A third generator ( APU GEN ), driven directly by the APU and producing the same output as each main engine generator, can replace either or both main engine generators at any time.

A ground power connector near the nosewheel allows ground power to be supplied to all busbars.

EMERGENCY GENERATOR

The blue hydraulic circuit drives an emergency generator that automatically supplies emergency AC power to the aircraft electrical system, if all main generators fail. This generator supplies 5 KVA of three-phase 115 and 200 V 400 Hz power.

STATIC INVERTER

A static inverter transforms DC power from Battery 1 into one KVA of single-phase 115 V 400 Hz AC power, which is then supplied to part of the AC essential bus. When the aircraft speed is above 50 kt, the inverter is automatically activated, if nothing but the batteries are supplying electrical power to the aircraft, regardless of BAT 1 and BAT 2 pushbutton positions. When the aircraft speed is below

50kt the inverter is activated, if nothing but the batteries are supplying electrical power to the aircraft, and the BAT 1 and BAT 2 push buttons are both on at auto.

BATTERIES

2 main batteries, each with a normal capacity of 23 Ah, are permanently connected to the two hot buses. Each battery has an associated Battery charge limiter ( BCL )

The BCL monitors battery charging and controls its battery contactor.

CIRCUIT BREAKERS ( C/BS )

The aircraft has 2 types of C/Bs:

Monitored ( GREEN ): When out for more than 1 min, the C/B TRIPPED warning is triggered on the ECAM.

Non- monitored (BLACK ).

The Wing Tip Brake (WTB ) C/Bs have red caps on them to prevent them from being reset. The C/B

TRIPPED warning on the ECAM indicates the location of the affected C/B.

ELECTRICAL PRIORITY

GEN 1 and 2 when operating have priority over the APU generator and over external power.

External power has priority over the APU generator when the EXT PWR pb switch is ON.

The APU generator or external power can supply the entire network.

The generators cannot be connected in parallel.