Polymer Crystallinity: Exercise Solutions & Properties

advertisement

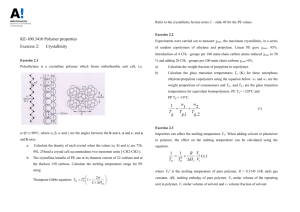

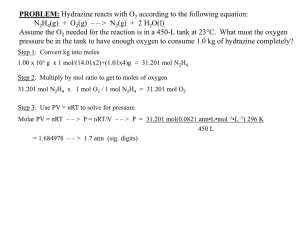

1 KE-100.3410 Polymer properties Solution to exercise 2: Crystallinity Exercise 2.1 Polyethylene is a crystalline polymer which forms orthorhombic unit cell, i.e. ===90ᵒC, where and are the angles between the b and c, a and c, and a and b axes. a. Calculate the density of each crystal when the values |a|, |b| and |c| are 736, 492, 254 and 2[-CH2-CH2-] units per cell. b. The crystalline lamella of PE can at its thinnest consist of 22 carbons and at the thickest 150 carbons. Calculate the melting temperature range for PE using Thompson-Gibbs equation: Tm Tm0 1 2 . L H m Tm = melting temperature of a lamellar with thickness L T = melting temperature of an infinitely thick and complete crystallite (414.2K) = free surface energy per unit area (79 x 10 -3 J / m2) Hm = Enthalpy change per volume (288 x 10 6 J / m3) L = lamellae thickness, ( ) = typical values for PE Solution 2.1 a) The volume for the orthorhombic unit of PE can be calculated: V = 73649225410-36 m3 = 9,2010-29 m3 Weight of the two molecules in the unit is: 2 m nM N 2 kg M 0.0280 9.30 1026 kg 1 NA mol 6.022 1023 mol And thus the density is: m 9.30 1026 kg kg 1010 3 29 3 V 9.20 10 m m b) 2 Thompson-Gibbs equation: Tm Tm0 1 L H m Lamella thickness can be calculated from the chain length of the monomer: 22 carbons (11 monomer units): L = 11254 pm =2.79 nm Substituting the values gives: Tm,min J 2 79 103 2 m 415K 1 330 K 57C 9 6 J 2, 79 10 m 288 10 3 m Tm,max J 2 79 103 2 m 415K 1 403K 130C 19,1109 m 288 106 J3 m The melting temperature range for PE is 57-130oC. Exercise 2.2 Experiments were carried out to measure max,, the maximum crystallinity, in a series of random copolymers of ethylene and propylene. Linear PE gave max= 95%. Introduction of 4 CH3 –groups per 100 main-chain carbon atoms reduced max to 50 % and adding 20 CH3 – groups per 100 main chain carbons max=0%. a) Calculate the weight fraction of propylene in copolymer. 3 b) Calculate the glass transition temperatures Tg (K) for these amorphous ethylene/propylene copolymers using the equation below. w1 and w2 are the weight proportions of comonomers and Tg,1 and Tg,2 are the glass transition temperatures for equivalent homopolymers. PE Tg = -120°C and PP Tg = -19°C. w w 1 1 2 T T T g g ,1 g ,2 (1) Solution 2.2 Introducing 4 CH3 –groups per 100 main-chain carbon atoms means the main chain contains 50 monomer units. Thus there are 4 propene groups per 46 ethene units. a) Molecular weights of the repeating units: M(C2H4) = 28.1 g/mol and M(C3H6) = 42.1 g/mol. Weight fraction of propene in copolymer where there is 4 CH3-groups: w1 n1M (Pr.) n1M (Pr.) n2 M ( Et .) 4 42.1 4 42.1 g mol g g 46 28.1 mol mol 0.115 11.5wt. % Weight fraction of propene in copolymer where there is 20 CH3-groups: w1 20 42.1 g mol g g 20 42.1 30 28.1 mol mol 0.500 50.0wt. % b) Using equation and solving for Tg: w w 1 1 2 T T T g g ,1 g ,2 The glass transition temperature for copolymer containing 11.5 wt.% propene: 4 1 0.115 1 0.115 Tg 160 K 113C Tg 273 19 K 273 120 K The glass transition temperature for copolymer containing 50 wt.% propene Tg = -82°C Exercise 2.3 Impurities can affect the melting temperature Tm. When adding solvent or plasticizer to polymer, the effect on the melting temperature can be calculated using the equation: 1 1 R Vu 0 (v1 ) Tm Tm H f V1 where Tm0 is the melting temperature of pure polymer, R = 8.3145 J/(K mol) gas constant, Hf melting enthalpy of pure polymer, Vu molar volume of the repeating unit in polymer, V1 molar volume of plasticizer and v1 volume fraction of plasticizer. Polydecamethyleneadiapate, CO (CH 2 )4 CO O (CH 2 )10 O n (density 0.99g/cm3) was plasticized using different amounts of dimethylformamide (CH3)2NCHO, (density 0.9445g/cm3) and the following melting temperatures were observed: v1 Tm (oC) 0.079 72.5 0.202 66.5 0.422 61.5 0.603 57.5 What is the melting temperature Tm0 and melting enthalpy H of the pure polymer? Solution 2.3 Calculate the molecular weights and molar volume for the components; (C16H28O4) and (C3H7NO): M (C16 H 28O4 ) (16 12.011 28 1.008 4 15.999) g g 284.396 mol mol 5 M (C3 H 7 NO) (3 12.011 7 1.008 14.007 15.999) V VM M Vu 2 2 2 2 n2 m2 2 g g 73.1 mol mol g 3 mol 287.3 cm g mol 0.99 3 cm 284.396 g M1 cm3 mol V1 77.4 1 0.9445 g mol 3 cm 73.095 Plotting the melting temperature as a function of weight fractions of solvent the cross point of R Vu 1 y-axis is 0 and the slope is Tm H f V1 The melting temperature and the melting enthalpy of the pure polymer can then be solved from the plot Tm0: 3.05E-03 1/Tm (K-1) 3.00E-03 2.95E-03 2.90E-03 2.85E-03 0 0.1 0.2 0.3 y = 2.40E-04x + 2.88E-03 R² = 9.73E-01 0.4 v1 0.5 0.6 0.7 6 1 2.88 103 K 1 0 Tm Tm0 1 346.74 K 73.6o C 3 1 2.88 10 K The slope enables the calculation of Hf for the polymer R Vu 2.40 104 K 1 H f V1 H f RVu V1 2.40 104 K 1 J cm3 287.3 K mol mol 128 kJ 3 cm mol 77.4 2.40 104 K 1 mol 8.3145 Exercise 2.4* 20 wt.% of a styrene oligomer having a number-average degree of polymerization of 7 was mixed with a commercial polystyrene sample having a number-average molecular weight of 100 000 g/mol. What is the Tg of the styrene oligomer? What is the Tg of the mixture? FoxFlory parameters for polystyrene are Tg = 373 K, K = 1.2105. Solution 2.4* The number-average molecular weight of the oligomer can be calculated from molecular weight of the repeating unit in the polymer or oligomer and the number-average degree of polymerization. Molecular weight of styrene is 104 g/mol and the number-average degree of polymerization of the oligomer is 7: M n M 0 X n 104 g g 7 728 mol mol The Fox-Flory equation can be used to calculate Tg of the oligomer: K 1.2 105 Tg ,oligomer T 373K K 208K 65o C 728 Mn g To obtain the Tg of the mixture, the inverse rule of mixtures can be applied (Fox equation). The Tg of the polystyrene is needed to calculate in order to use Fox equation: 7 Tg ,PS Tg K 1.2 105 373K K 374 K 101o C 100000 Mn 1 w w 0.2 0.8 1 1 2 0.003101 Tg Tg ,1 Tg , 2 208K 374 K K Tg ,mixture 1 K 323K 50o C 0.003091 Exercise 2.5* The following empirical equation can be applied when calculating the glass transition temperature Tg for copolymers and blends w w 1 1 2 Tg Tg ,1 Tg ,2 where w1 and w2 are the weight fractions of polymers and Tg,1 and Tg,2 are glass transition temperatures of the polymers. The effect of plasticizer on polymer melting temperature Tm can be estimated with the equation: 1 1 R Vu 0 (v1 12v12 ) Tm Tm H f Vm,1 where Tm0 is the melting temperature of pure polymer, R = 8.3145 J/(K mol) gas constant, Hf melting enthalpy of pure polymer, Vu molar volume of the repeating unit in polymer, Vm,1 molar volume of the plasticizer, v1 volume fraction of plasticizer and 12 is interaction parameter for polymer-plasticizer. How much plasticizer (Tg = -80oC) should be added to the Nylon 66 (C12H22O2N2) sample to obtain Tg of 25oC? What would be the melting temperature; Vm,1 = 200cm3/mol and = 0.40, for Nylon66 Hu = 195.6 J/g, = 1.088 g/cm3, Tm0 = 265oC, Tg = 50 oC. Density of plasticizer= 1.05 g/cm3. 8 Solution 2.5 The weight fraction of polymer is w2 1 w1 and then weight fraction of the plasticizer can be solved from the equation: w w w 1 w1 1 1 2 1 Tg Tg ,1 Tg ,2 Tg ,1 Tg ,2 Tg ,1Tg ,2 w1 Tg Tg ,1 Tg ,2 Tg ,1 193.15K 323.15K 193.15K 298.15 K 0.1246 323.15K 193.15K So the amount of the plasticizer should be 12 wt.%. In order to calculate the melting temperature for the sample, one needs know the volume fraction of the plasticizer v1: v1 m1 w1m V1 1 w w w2 2 1 1 1 1 m m V 1 g g 0.8754 1.088 3 ) 3 cm cm 0.1285 g 1.05 3 cm 0.1246 (0.1246 1.05 Molar volume of the repeating unit (C12H22O2N2) of Nylon 66 ([-NH-(CH2)6-NH-CO(CH2)4CO-]n): g 3 mol 208 cm Vu 2 1.088 g mol cm3 M0 226 The melting temperature of the polymer is: 1 1 R Vu 0 (v1 12v12 ) Tm Tm H f Vm,1 9 Tm 1 1 R Vu (v1 12 v12 ) 0 Tm H f Vm ,1 1 J cm3 8.3145 208.0147 (0.1285 0.4 0.12852 ) 1 K mol mol J g cm3 538.15K 195.6 226.32 200 g mol mol 531.34 K 258.19o C Melting temperature is lowered from 265oC to 258 oC, when 12-wt.% of plasticizer is added.