3. Environmental Policy

advertisement

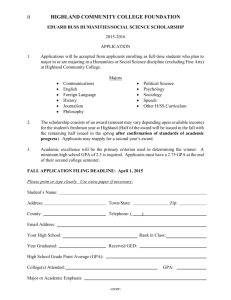

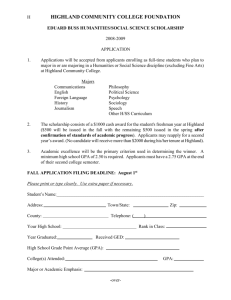

Verified EMAS Statement 16 March 2012 CE Rosser EMAS Verifier Highland Spring Ltd Ochils Site Environmental Statement 2011 TABLE OF CONTENTS 1. Purpose & Scope __________________________________________________ 3 2. Context __________________________________________________________ 3 2.1 Highland Spring Background____________________________________ 3 2.2 Highland Spring Operation _____________________________________ 3 2.3 Organic Accreditation _________________________________________ 4 3. Environmental Policy _______________________________________________ 5 3.1 Environmental Policy Statement _________________________________ 5 3.1 Policy Statement ___________________________________________ 5 4. Description of EMS ________________________________________________ 6 4.1 Significant Environmental Aspects and Impacts _____________________ 6 4.1.1 Catchment area boreholes _________________________________________ 6 4.1.2 Purchase of raw materials and services _______________________________ 7 4.1.3 Packaging the product ____________________________________________ 7 4.1.4 Admin _________________________________________________________ 7 4.1.5 Distribution _____________________________________________________ 8 4.1.6 Disposal _______________________________________________________ 8 4.1.7 General to the entire Site __________________________________________ 9 5. Targets and Objectives ____________________________________________ 10 6. Further Information________________________________________________ 13 6.1 Validation Statement _________________________________________ 13 6.2Contact Information __________________________________________ 14 Highland Spring Environmental Statement 2011 1. Purpose & Scope This document is Highland Spring Ltd’s seventh annual Environmental Statement and presents its performance for the period January to December 2011 at the Ochils site in Blackford. This environmental statement is part of Highland Spring’s overall commitment to ensure that the impacts from all of our activities are fully understood and minimised. 2. Context 2.1 Highland Spring Background Highland Spring was established in 1979 and commenced trading in April 1981. The group bottles Natural Mineral Water, Spring Water and Bottled Drinking Water, in accordance with Scottish Statutory Instrument 2007 No. 435 “The Natural Mineral Water, Spring Water and Bottled Drinking Water Regulations (Scotland) Regulations 2007” (and subsequent amendments) which implement the European Directive 80/777/EEC and its modifying Directives 96/70/EC and 2003/40/EC as well as Council Directive 98/83/EC. The company is based in the village of Blackford, Perthshire, on the edge of the A9 approximately twelve miles from Stirling and twenty from Perth. Highland Spring has two bottling sites in Blackford: the main Highland Spring site with extensive warehouse space and the Gleneagles site (acquired in April 2001), which produces its own stylish Gleneagles brand and “Water Media” products. This EMAS statement covers both sites. At these sites Highland Spring employs around 300 staff. The factories are dedicated to the bottling of natural water in modern bottling plants. 2.2 Highland Spring Operation The Spring Water regulations require water to be abstracted from an underground source which is protected against pollution. Rainfall on the upper slopes of the Ochil Hills percolates into the ground and flows through the rock strata downslope to the boreholes. The regulations require that the product must be of potable (drinkable) quality as it emerges from the ground. It is imperative that the risk of pollution of the ground, and therefore the water, is kept to an absolute minimum. On average the water takes 15 years to flow underground from the rock outcrop at the top of the hill to the boreholes. During this time bacteria from the surface die off and the water dissolves minerals from the rock. The water is protected from the surface by a layer of impervious rock or clay above the water bearing rock. Boreholes are used to abstract the clean water from deep underground to the surface. They are constructed in such a way as to prevent water from the surface contaminating the deep groundwater. The water is pumped to the factory through underground stainless steel pipes, and therefore is not exposed to the air or environment at the surface. Page 3 Highland Spring Environmental Statement 2011 To ensure that no contaminants can enter the water, Highland Spring Ltd has achieved organic certification for the hillside. This means that no weedkillers, insecticides or fertilisers can be applied to the land. In addition to this Highland Spring does not allow livestock, cultivation or housing on the land because these activities can also pollute the water. Only a very limited number of maintenance vehicles are allowed on the hillside. Highland Spring is happy to see wildlife and walkers on the land as these do not represent a risk to the product. When the water reaches the plant it is filtered to remove any rock particles, but undergoes no treatment before being bottled (except carbonation to produce our range of sparkling products). Still and sparkling water is presented in a wide range of packaging formats in glass and PET (a type of plastic) to suit all consumer needs. 2.3 Organic Accreditation The Soil Association awarded Organic status to the catchment area of 621 hectares in 2001. In 2005 we gained approval for another 398 hectares to allow expansion of our sources. In May 2008 another 30 hectares converted to organic. Therefore in 2011 we had 1049 hectares which were organic. Though European and UK legislation does not make provision to gain organic status for water, Highland Spring is demonstrating its commitment to the protection of the sources by gaining certification for the catchment area. As a result of this we are able to include the following phrase on the labels; “Naturally filtered through land certified as organic by the Soil Association and drawn from a protected source, Highland Spring is 100% Scottish Natural Spring Water”. Page 4 Highland Spring Environmental Statement 2011 3. Environmental Policy 3.1 Environmental Policy Statement 3.1 Policy Statement Highland Spring Ltd was formed in 1979 and is located in Blackford, Perthshire. Our modern production facility is located close to the Ochil hills, home to our organically accredited catchment area which ensures the protection of our source of natural water. Employing over 300 staff, we have the biggest UK produced brand of Bottled Water with 95% of our output sold in the UK. The Gleneagles Spring Water plant was acquired in April 2001 and is also located in Blackford. Both production facilities are dedicated to the bottling of natural source water in a range of packaging formats to suit all consumer needs. 1. Highland Spring is committed, without prejudice to the development and sustainability of its business, to minimise the impact of its operations on the environment. 2. Highland Spring will promote practices to ensure that the organisation meets compliance, as a minimum standard, with all regulatory and legislative requirements and will seek to achieve continual improvement in environmental performance. 3. Areas of specialist responsibility are allocated to key personnel to monitor and report on environmental achievement. The Environment Team, led by a senior member of management, will carry out reviews of procedures and trends, setting objectives and targets to effectively control waste, emissions, discharges, land contamination and the consumption of materials, fuel and energy. Priority will be given to ensuring the protection of the catchment area for our water. 4. In accordance with our continuing policy to protect the integrity of our Spring Water, Natural Mineral Water and Scottish Natural Water sources and catchment area, Highland Spring will endeavour to minimise adverse environmental effects and prevent pollution in daily operations and any new developments of the business. 5. Without compromise or restriction to trade and where economically viable Highland Spring will address product development through the utilisation of recyclable materials. These materials themselves and packaging components may include recyclable materials, provided their use does not prejudice the integrity of the product water. 6. Highland Spring will promote, in its staff training programmes, the implementation of good environmental practices. 7. Highland Spring has an environmental policy, which is reviewed regularly. 8. A copy of this policy, which is subject to review, is available to all company employees, suppliers and customers and to any other interested party. CHIEF EXECUTIVE: Les Montgomery DATE: 1st March 2012 Page 5 Highland Spring Environmental Statement 2011 4. Description of EMS The following environmental management system has been developed to fit into Highland Spring’s organisational format and conforms to the ISO14001 standard. The system helps us to achieve continual improvement and control by utilising the following components which are requirements of EMAS: Area Policy: Manual: Procedures: Programme: Audit: Public reporting: Description This states the overall aim and commitments This describes our compliance with EMAS Regulations and ISO 14001 Standards and links with the other parts of the system These prescribe how certain activities (those that require control) should be carried out. This includes waste disposal and emergency procedures This is an ongoing programme of objectives and targets to drive improvement Both internal and external audits are used to ensure that the system is working efficiently and that the programme is progressing This statement outlines our significant environmental aspects and current performance The Environmental Delegate manages the system, scheduling yearly management reviews. 4.1 Significant Environmental Aspects and Impacts 4.1.1 Catchment area boreholes Activity Impact / Control Installation and use of boreholes Pollution of catchment. When installing boreholes we recognise environmental risk to ground water and thus this activity is strictly controlled. Resource Use. Our management regime for the source has been developed with our Consultant Hydrogeologist and ensures that the volumes abstracted have no significant effect on the environment. Highland Spring has been granted an abstraction licence by SEPA (Scottish Environmental Protection Agency). Potential pollution of groundwater. There is no human habitation or farming on the catchment area or use of pesticides, herbicides or fertilisers use on the catchment area. Part of the catchment is certified Organic by the Soil Association since July 2001, with a later addition in August 2005. Boreholes are constructed infrequently thus there is little or no disturbance in the catchment area. This has a positive effect on the land which encourages a wide diversity of Abstraction of groundwater Catchment organic status Page 6 Highland Spring Environmental Statement 2011 Activity Impact / Control flora and fauna. 4.1.2 Purchase of raw materials and services Activity Use and disposal of filters Impact / Control Landfill. There are also various issues associated with materials use (including natural resources use, the energy used during production and transportation issues). Purchase of goods through our assessed By using vendor rating and a supplier supply chain questionnaire it is possible to create a positive effect by encouraging our supplier chain to improve their environmental performance. 4.1.3 Packaging the product Activity Glass scrap Impact / Control Waste for recycling. Any glass used on site that is not sent to the customer is recycled. At Gleneagles this does not happen due to the fact that only small amounts of glass are produced and thus not very much waste. Also the glass used at H/S contains a proportion of post consumer recycled material. PET Scrap (bottles or PET preforms) and Waste for recycling. Shrink wrap These items are all recycled thus significantly reducing their impact on the environment. Oils for compressors Contamination of land and water. The oil is stored on site safely so as to prevent pollution and is disposed of offsite. Inks for date codes and inks used on the Contamination of water. labels are produced off the premises and Inks are carefully controlled so as to do not contain VOCs or heavy metals. prevent pollution. 4.1.4 Admin Activity Printer/copier cartridge recycling Impact / Control Recycling prevents materials going to landfill and being wasted. Disposal of obsolete computers and Computers are sent for recycling. Other other electrical equipment equipment disposal complies with WEEE regulations. Page 7 Highland Spring Environmental Statement 2011 4.1.5 Distribution Activity Impact / Control Accidental fuel / oil leaks from vehicles Contamination of land and water. and delivery of heating oil/storage Fuel and oil have the potential for water and / or land contamination. Use of contractors to transport finished Emissions from transportation contribute product. to global climate change and air quality reduction. Noise pollution is also generated. Efforts to improve transport efficiency being made 4.1.6 Disposal Activity Impact / Control Creation of mixed waste for landfill on Includes transportation emissions and site impacts associated with landfill (habitat destruction, leachate production, land contamination, methane production). Cardboard boxes sold for re-use/returned Since these items are re-used or to supplier/ cardboard sent for use in recycled this significantly reduces their pulp impact. Plastic Packaging (internal) Packaging going to the customer (glass Through lightweighting our product (see and PET ) Achievements section) we have reduced the amount of packaging sent to the customer. Local councils often provide Glass recycling facilities. Plastic in this country is often not recycled but the effect of it can be reduced if recycling facilities are provided. Other outgoing secondary and tertiary There are various issues associated with packaging; shrink wrap, trays. materials use (including natural resources use, the energy used during production and transportation issues) but the main issue is its end of life (i.e. landfill). Product pallets for the UK These pallets work on a return principle where they are re-used within the system. Diluted cleaning agents, Peracetic acid, These chemicals are carefully stored so caustic hot wash and ozone as to minimise the potential for pollution. Ozone is generated electrically as and when required. Use of battery recharged forklifts Our batteries last 4 to 5 years as they are rechargeable. Batteries contain materials harmful to the environment. Page 8 Highland Spring Environmental Statement 2011 Activity Track lubricant used to lubricate the lines (conveyor belts) when glass bottles are being filled Impact / Control A new dry lube system has been installed which has a number of environmental advantages. These include a reduction of water consumption and elimination of detergent use. The volume of trade effluent is reduced. Burning of gas for heating the boiler. The burning of gas produces greenhouse Use of propane gas cylinders filled on gas which contributes to global climate site for forklift trucks change. Asbestos roof at Gleneagles Special care must be taken if the roof is to be dismantled as it can cause harm to human health and has to be treated as special waste. 4.1.7 General to the entire Site Activity Gas oil heating boilers. Accidental leakage of gas oil Impact / Control The burning of diesel produces greenhouse gas, which contributes to global climate change. The burning of oil also produces SOx and NOx. Highland Spring has three discharge In late 2007/ early 2008 the domestic consents to the river Allan for the effluent was connected the Blackford following activities listed below: Waste Water Treatment Works. This helps further reduce risk of contamination Production of domestic effluent of local water courses. from our effluent treatment plant Trade Effluent now uses the same route Trade effluent discharge Site drainage discharge which further reducing the risk levels for the runs through petrol interceptors site. into the Allan water Gleneagles has one discharge consent The consents are still in place. to the River Allan for the following activity. Trade effluent discharge. Employee travel to work Many people employed by Highland Spring live in Blackford. Those who do travel to work independently contribute to global climate change. Metal scrap There is little metal scrap The use of natural resources without recycling puts a strain on the environment. It also creates landfill. Use of domestic water supplies for Use of water has a relatively small employee toilets etc environmental impact in Scotland – due to high rainfall rates. Impacts relate to the use of a natural resource and water treatment. Page 9 Highland Spring Environmental Statement 2011 Activity Use of energy on the whole site. Blowmoulding which requires water and uses electricity Impact / Control The use of electricity itself has no chilled environmental impact; it is the source of electricity that has the overall environmental impact, including global warming. These activities with their associated impacts are determined through the use of a procedure to define importance and also through the discussion within the Environment Committee. This procedure takes into account the views of interested parties, legal commitments, policy commitments and the potential for any emergency situations. Our Environmental legal commitments are listed in our Register of Legislation (this is available on request). Following an initial environmental review it was determined that our most significant effects on the environment are our use of energy, packaging (including waste) and transport. A management programme was developed to control these with the help of managers, and objectives and targets were set to reduce our impact. Our objectives and targets can be found in the next section. 5. Targets and Objectives New legislation (see below) requires reporting on defined parameters in a specific way. New EMAS Regulation EC No 1221/2009 This new regulation was adopted on 25 November 2009, and introduces new Environmental Reporting requirements on participating companies. Core environmental indicators and methods of reporting them are specified. These are laid out below as the Regulation requires. This information will provide a baseline for future year on year comparisons, and will form the basis for our Objectives and Targets reporting. Energy Efficiency: Target 1% reduction per year Total Direct Energy Use: 14,388.81 MWh of electricity. It does not include gasoil which is used for heating purposes only. Total Output: 248793 Tonnes of Water Bottled Ratio: 0.058 MWh/Tonne of Water Bottled This represents a 10.7% reduction from 2010 in power used per tonne bottled. Work has been done to analyse power consumption in more detail, by function. Systems have been installed to record consumption on an hourly basis and this is providing detailed information on usage at different times. No energy was from renewables. Page 10 Highland Spring Environmental Statement 2011 Material Efficiency: Target 1% reduction per year Total Material Use in Tonnes: Glass Plastic Paper 5797.7 8733.1 1912.6 Total Tonnes of Water Bottled: 248,793 Ratio: Tonnes of Material per Tonne of Water Bottled Glass Plastic Paper 0.0233 (reduction of 15% from last year) 0.0351 (reduction of 9% from last year) 0.0077 (reduction of 7% from last year) These variances are due to changes in the sizes and types of products sold, and this has the effect of altering the ratios. Water: Target 1% reduction per year Total water to the factory: 312,936 Tonnes Total output: Ratio: 248,793 Tonnes 1.26 Tonnes per tonne bottled which represents an increase of 0.2% on 2010. It is difficult to reduce this figure because our water use is currently very efficient. Waste: Target 1% reduction per year Non Hazardous Waste Produced in Tonnes Plastic Glass Paper Landfill 118.1 51.06 85.4 90.1 Ratio: Tonnes of Waste per Tonne of Water Bottled Plastic Glass Paper Landfill 0.00047 0.000205 0.00034 0.00037 The figures for the plastic and paper sent to the waste stream were slightly down on last year, but glass has increased. None of these figures is significant. However, there was a significant drop in the waste to landfill of 20%. This was achieved by better control of material segregation. Page 11 Highland Spring Environmental Statement 2011 Hazardous Weight of hazardous waste in Tonnes: 1.79 Ratio: tonnes hazardous material per tonne of water bottled: 0.0000072 Biodiversity: no target set Area of built up land: 23,211m2 Area of organic land: 10,484,200m2 Ratio: m2 land per tonne water bottled Area of built up land: 0.09 Area of organic land: 42.14 This represents a slight decrease on last year, but is purely caused by the increase in tonnage of water bottled between 2010 and 2011. There has been no change to the size of the built up or organic land. Emissions: Target 1% reduction per year Greenhouse Gas Emissions GHG emissions from use of electricity, gas oil and loss of refrigerant from chillers has been calculated: 327207 tonnes CO2 Ratio: tonnes CO2 per tonne water bottled CO2: 1.32 Air Emissions Total gas oil used: 80.11 tonnes Total NO2 generated: Total SO2 generated: Total Particulate Matter generated: 96kg 128kg 6.9kg Ratio: kg material emitted per tonne water bottled NO2: SO2: PM: 0.00039 0.0005 0.00003 This represents over a 50% decrease in emissions because of a large reduction in the fuel oil used on site. This was achieved through close control and monitoring of the use of space heaters, but also because the winter months in 2011 were considerably milder than the extreme cold conditions of 2010. Page 12 Highland Spring Environmental Statement 2011 6. Further Information 6.1 Validation Statement ENVIRONMENTAL VERIFIER’S DECLARATION ON VERIFICATION AND VALIDATION ACTIVITIES Lloyd’s Register Quality Assurance Ltd., with EMAS environmental verifier registration number UKV-005 and accredited for the scope: “The management and reporting of the significant environmental aspects associated with the sources, bottling, packaging and distribution of still and sparkling natural waters.” (NACE code C 11.07 - Production of mineral waters and other bottled waters): Highland Spring Ltd Stirling Street, Blackford Auchterarder, Perthshire UK Registration number: UK-000122 meets all requirements of Regulation (EC) No 1221/2009 of the European Parliament and of the Council of 25 November 2009 on the voluntary participation by organisations in a Community Eco-Management and Audit Scheme (EMAS). By signing this declaration, LRQA declares that: the verification and validation has been carried out in full compliance with the requirements of Regulation (EC) No 1221/2009, the outcome of the verification and validation confirms that there is no evidence of noncompliance with applicable legal requirements relating to the environment, the data and information presented in the Environmental Statement 2011 of the organisation reflect a reliable, credible and correct image of all the organisation’s activities within the scope mentioned in the environmental statement This document is not equivalent to EMAS registration. EMAS registration can only be granted by a Competent Body under Regulation (EC) No 1221/2009. This document shall not be used as a stand-alone piece of public communication. LRQA Ref No: LRQ4000559 Date of verification: 16 March 2012 Verification Expiry: 31 March 2012 Date of validation: 16 March 2012 Validation Expiry: 21 March 2012 C.E. Rosser, EMAS Lead Verifier On behalf of LRQA Ltd., Hiramford, Siskin Drive, Middlemarch Office Village Coventry, UK CV3 4FJ Page 13 Highland Spring Environmental Statement 2011 6.2Contact Information We are always keen to obtain feedback about our Environmental efforts, so if you have any questions or comments please contact our Environmental Representative through our head office as follows: Highland Spring Ltd Stirling Street Blackford Auchterarder Perthshire PH4 1QA Telephone: 01764 660500 Website: www.highland-spring.com Page 14