MORA-SRS - FFG 7. Rahmenprogramm

advertisement

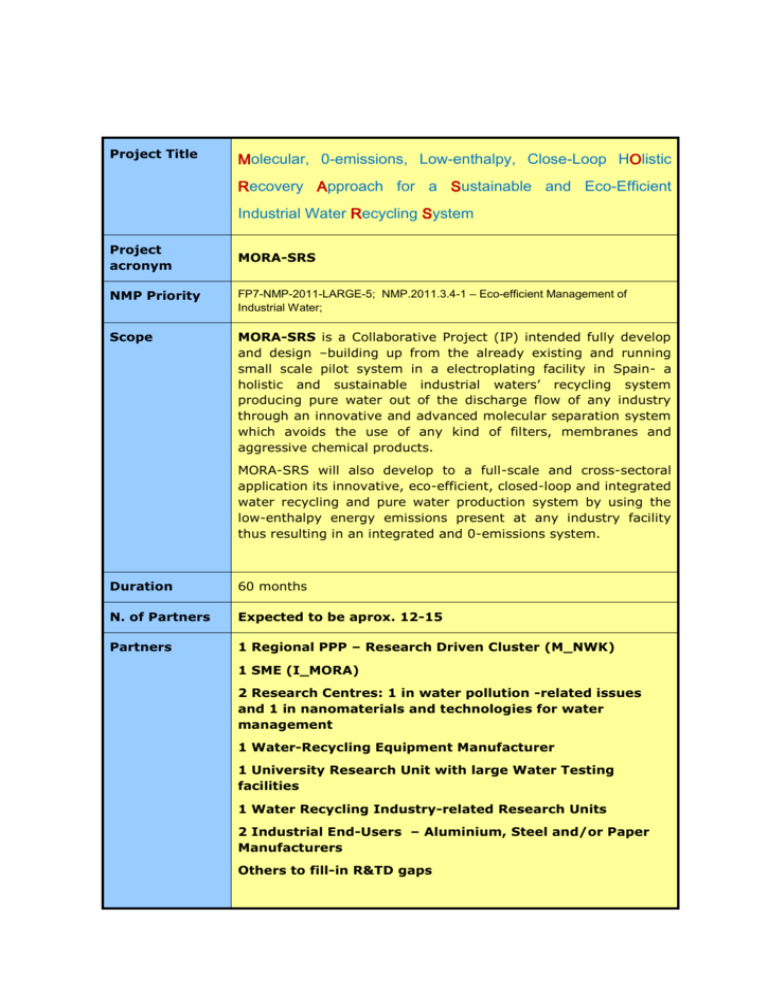

Project Title Molecular, 0-emissions, Low-enthalpy, Close-Loop HOlistic Recovery Approach for a Sustainable and Eco-Efficient Industrial Water Recycling System Project acronym MORA-SRS NMP Priority FP7-NMP-2011-LARGE-5; NMP.2011.3.4-1 – Eco-efficient Management of Industrial Water; Scope MORA-SRS is a Collaborative Project (IP) intended fully develop and design –building up from the already existing and running small scale pilot system in a electroplating facility in Spain- a holistic and sustainable industrial waters’ recycling system producing pure water out of the discharge flow of any industry through an innovative and advanced molecular separation system which avoids the use of any kind of filters, membranes and aggressive chemical products. MORA-SRS will also develop to a full-scale and cross-sectoral application its innovative, eco-efficient, closed-loop and integrated water recycling and pure water production system by using the low-enthalpy energy emissions present at any industry facility thus resulting in an integrated and 0-emissions system. Duration 60 months N. of Partners Expected to be aprox. 12-15 Partners 1 Regional PPP – Research Driven Cluster (M_NWK) 1 SME (I_MORA) 2 Research Centres: 1 in water pollution -related issues and 1 in nanomaterials and technologies for water management 1 Water-Recycling Equipment Manufacturer 1 University Research Unit with large Water Testing facilities 1 Water Recycling Industry-related Research Units 2 Industrial End-Users – Aluminium, Steel and/or Paper Manufacturers Others to fill-in R&TD gaps Budget 10.000.000 – 12.000.000€ N. of WPs 12 WPs TBD N. of Deliverables TBD Major Objectives The project will target and address: Designing, implementing and testing large-scale and cross-sectoral water recovery and recycling system able to fully recuperate al raw materials mixed in the downstream industrial water thus achieving a full and complete “recycling” performance instead of the current “neutralizing” principle. Designing, implementing and testing an integrated approach towards optimised process development and design that will allow a general (heat, solvents, raw materials, by-products) waste minimization, treatment and recycling coupled with the use of internal and already-existing low-enthalpy energy sources (emissions) within the industrial processes. Investigating novel nanomaterials and energyefficient technologies to improve cost-efficiency, equipment endurance while reducing investment needed thus improving economics of MORA-SRS for end-users. Conducting fundamental research to achieve novel industrial water treatment cycles reproducing the natural water cycle within MORA-SRS. • Conducting fundamental research to fully develop and test a water treatment system able to manage evaporation and condensation processes at very low temperatures and with continuous pressureequilibrium processes. Generating a set of quantum-leap changes in the industrial water management equipments and technologies themselves and also by means of a radical change in the overall QoW output performance of the models used to-date. Actively involve end-users through consortium membership to account for MORA-SRS validation under real process conditions in a cross-sectoral framework once the already existing and running small scale pilot system in a electroplating facility in Spain has been fully expanded in terms of scalability and adaptability to different industrial processes Designing and implementing a QoW assessment framework, including the tools for monitoring and measurement of QoW, including activity-based, enduser, final utilization automatic inference methods and the interfaces for decision making. Tackling the emergent biological pollution risk issues once “pure water” status has been achieved and prior to water discharge (holistic approach).. Developing management architecture and systems to allow self-organising and self-healing operations, cooperative network composition, service support, and portability across multiple industrial sectors and business domains.

![School [recycling, compost, or waste reduction] case study](http://s3.studylib.net/store/data/005898792_1-08f8f34cac7a57869e865e0c3646f10a-300x300.png)