20110331_ijapr article - International Journal of Advances in

advertisement

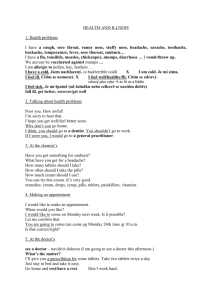

FORMULATION AND EVALUATION OF FAST DISSOLVING TABLETS OF PIOGLITAZONE C.Sadak Vali*1, Department of Pharmaceutics, Fathima Institute of Pharmacy, Kadapa. A. P. Mohammad Rayees Ahmad1, Department of Pharmaceutics, Fathima Institute of Pharmacy, Kadapa. A. P. Mitta Raghavendra2, Department of Pharmacology, Fathima Institute of Pharmacy, Kadapa. A. P. Correspondence: C.Sadak Vali, Department of Pharmaceutics, Fathima Institute of Pharmacy, Kadapa- 516 002. A.P. INDIA. Mobile: +91 9052520483 E-mail: sadak_chettukrindi@hotmail.com ABSTRACT The purpose of this research was to develop fast dissolving tablets of pioglitazone. Tablets containing pioglitazone, croscarmellose & crospovidone were prepared by direct compression technique. The tablets were evaluated for weight variation, hardness, percentage friability, wetting time, and disintegration time. Nine formulation having superdisintegrants in different concentrations levels were prepared to access their efficiency and critical concentration level. Tablets containing croscarmellose sodium along with crospovidone is showing excellent results as compare to other formulations. KEYWORDS: Fast dissolving tablet, pioglitazone, croscarmellose, crospovidone. INTRODUCTION Tablets are the most widely used dosage form because of its convenience in terms of self administration, compactness, and ease in manufacturing. Geriatric and paediatric patients experience difficulty in swallowing conventional tablets, which leads to poor patient compliance. Traditional tablets and capsules administered with 250 ml of water may be inconvenient or impractical for such patients. To overcome this, scientists have developed innovative drug delivery systems known as "melt in mouth" or "mouth dissolve (MD)" tablets. Fast Dissolving tablets disintegrate/dissolve/disperse quickly in saliva. Fast dissolving tablets can be administrated without water, anywhere, anytime to geriatric and paediatric patients. They are also suitable for the mentally ill, the bedridden, and patients who do not have easy access to water. The benefits, in terms of patient compliance, rapid onset of action, increased bioavailability, and good stability make these tablets popular as a dosage form of choice in the current market1, 2 .The disintegrated mass can slide down smoothly along the oesophagus with the help of saliva, so even people who have swallowing or chewing difficulties can take it with ease. The sublingual route usually produces a faster onset of action than orally ingested tablets and the portion absorbed through the sublingual blood vessels bypasses the hepatic first-pass metabolic processes3-5. The basic approach used in the development of the fast-dissolving tablet is the use of superdisintegrants. Croscarmellose sodium and crospovidone were screened in the present study, and the best one was used for further studies. Another approach used in developing fast dissolving tablets is maximizing pore structure of the tablets. Freeze-drying6, direct compression and vacuum-drying techniques are commonly used to maximize the pore structure of tablet matrix. Freeze drying is cumbersome and it yields a fragile and hygroscopic product. Therefore, it was decided to adopt the direct compression technique in the present investigation. It is likely that a porous hydrophilic matrix will easily pick up the disintegrating medium and break quickly.MDT can be formulated using various methods. Some of them involve increasing the porosity of the tablet and decreasing the disintegration time (DT) 7. Superdisintegrants are used that swell or absorb water rapidly to disintegrate the tablet8. Technologies like Zydis based on lyophilization yield tablets that dissolve in a few seconds. Most of the techniques aim at lowering the DT, but doing this always compromises the mechanical strength. Zydis tablets need special packaging and patient counseling for removing the tablets from the strip9. Hence, the objective of this work was to formulate and optimize mouth-dissolving tablets of pioglitazone HCl that disintegrate in a few seconds and still have good mechanical strength. Pioglitazone is a prescription drug of the class thiazolidinedione with hypoglycemic (antihyperglycemic, antidiabetic) action. Pioglitazone reduces insulin resistance in the liver and peripheral tissues; increases the expense of insulin-dependent glucose; decreases withdrawal of glucose from the liver; reduces quantity of glucose, insulin and glycated haemoglobin in the bloodstream. Following oral administration, in the fasting state, pioglitazone is first measurable in serum within 30 minutes, with peak concentrations observed within 2 hours. Food slightly delays the time to peak serum concentration to 3 to 4 hours, but does not alter the extent of absorption. MATERIALS AND METHODS: The drug pioglitazone Hydrochloride was a generous gift sample from Suzikem Pharmaceuticals, Hyderabad. Croscarmellose sodium, crospovidone were supplied from Signet Pharmaceuticals (Mumbai). Magnesium stearate, talc was supplied from S.D. Fine Chemicals (Mumbai). Mannitol was purchased from Merck India Ltd, Mumbai, India. Other reagents and organic solvents used were of analytical grade. Preparation Of Pioglitazone Tablets Various techniques can be used to formulate rapidly-disintegrating or dissolving tablets10,11. Direct compression, one of these techniques, requires the incorporation of a superdisintegrants into the formulation, or the use of highly water-soluble excipients to achieve fast disintegration of tablets. Watanabe et al12and Bi et al 13 were the first to evaluate the ideal excipients proportions and other related parameters using a superdisintegrant in order to formulate durable fast disintegrating tablets for oral administration. Pioglitazone mouth dissolve tablets were prepared according to the formulae given in Table 1. The raw materials were passed through a screen (40 mesh) prior to mixing. Pioglitazone (30 mg) was mixed with the other excipients and compressed on a single-punch tablet machine (REMIK, mini press, B-tooling machine, India) equipped with round 6-mm punches. EVALUATION OF BLENDS The quality of tablet, once formulated by rule, is generally dictated by the quality of physiochemical properties of the blend. There are many formulation variables and process variables involved in the mixing step which will affect the characteristics of blends produced. The blends were characterised by mass-volume relationship (bulk density, tapped density, Hauser’s ratio, compressibility index) and flow properties (static angle of repose) 14. EVALUATION OF THE PREPARED TABLETS The crushing strength of the tablets was measured using a Monsanto hardness tester (Sheetal Scientific Industries Mumbai, India). The friability of tablets was measured using a Roche Friabilator (Electrolab). Five tablets were selected randomly from each formulation batch and tested for hardness, disintegration time and wetting time15-19.The wetting time of the tablets was measured using a simple procedure. Five circular tissue papers of 10-cm diameter were placed in a Petri dish with a 10-cm diameter. Ten millilitres of water containing eosin, a watersoluble dye was taken in the Petri dish. A tablet was carefully placed on the surface of tissue paper. The time required for water to reach the upper surface of the tablets was noted as the wetting time. The disintegration time was measured using a modified disintegration method. RESULTS AND DISCUSSION The use of superdisintegrants for preparations of fast dissolving tablets is highly effective and commercially feasible. These superdisintegrants accelerate disintegration of tablets by virtue of their ability to absorb a large amount of water when exposed to aqueous environment. The absorption of water results in breaking of tablets and therefore faster disintegration is reported to have an effect on dissolution characteristics as well. A prepared fast-dissolving tablet gets dispersed in the mouth quickly and released the drug as early as compared to its formulated conventional tablets. Two different superdisintegrants namely Croscarmellose sodium and crospovidone were tried to achieve fast dispersion of tablets. Blends evaluated for angle of repose shown excellent flowability. CONCLUSION Tablets containing Croscarmellose sodium along with crospovidone formulation F-6 shown fastest disintegration, as shown in (figure-3). Characteristics of tablets are further tabulated in Table-2. The study shows that the dissolution rate of pioglitazone can be enhanced to a great extent by direct compression technique with the addition of mixture of superdisintegrants. ACKNOWLEDGEMENT The authors are thankful to BAL PHARMA, Banglore for providing the gift sample of Pioglitazone and also thankful to management of Fathima Institute of Pharmacy for providing the all facilities to carry out this research work. REFERENCES 1. Chang R, Guo X, Burnside B, Couch R. A review of fast dissolving tablets. Pharm Tech. (North America). June 2000;52-58. 2. Bi Y, Sunada H, Yonezawa Y, Dayo K, Otsuka A, Iida K. Preparation and evaluation of a compressed tablet rapidly disintegrating in oral cavity. Chem Pharm Bull (Tokyo). 1996; 44: 2121-2127. 3. Birudaraj R, Berner B, Shen S, Li X. Buccal permeation of buspirone: mechanistic studies on transport pathways. J Pharm Sci. 2005 ; 94:70-78. 4. Ishikawa T, Koizumi N, Mukai B. Pharmacokinetics of acetaminophen from rapidly disintegrating compressed tablet prepared using microcrystalline cellulose (PH-M-06) and spherical sugar granules. Chem Pharm Bull (Tokyo). 2001; 49: 230-232. 5. Price TM, Blauer KL, Hansen M, Stanczyk F, Lobo R, Bates GW. Single-dose pharmaco- kinetics of sublingual versus oral administration of micronized 17 beta-estradiol. Obstet Gynecol. 1997; 89:340-345. 6. Corveleyn S, Remon JP. Formulation and production of rapidly disintegrating tablets by lyophilization using hydrochlorthiazide as a model drug. Int J Pharm. 1997; 152:215-225. 7. Biradar S, Bhagavati S and Kuppasad. Fast dissolving drug delivery system: a brief overview. Internet J Pharmacol. 2006; 4(2):54-58. 8. Chang R, Guo X, Burnside B, Couch R. Fast-dissolving tablets. Pharm Technol 2000; 24(6):52–58. 9. Bogner R, Meghan F. Fast dissolving tablets. US Pharmacist. 2005; 27: 03. 10. Allen LV. Rapid-dissolve technology: an interview with Loyd V. Allen. Int J Pharm Technol. 2003; 7: 449-450. 11. Fu Y, Yang S, Jeong SH, Kimura S, Park K. Orally fast disintegrating tablets: developments, technologies, taste-making and clinical studies. Crit Rev Ther Drug Carrier Syst. 2004; 21:433476. 12. Watanabe Y, Koizumi K, Zama Y, Kiriyama M, Matsumoto Y, Matsumoto M. New compressed tablet rapidly disintegrating in saliva in the mouth using crystalline cellulose and a disintegrant. Biol Pharm Bull. 1995; 18: 1308-1310. 13. Bi Y, Sunada H, Yonezawa Y, Danjo K, Otsuka A, Iida K. Preparation and evaluation of a compressed tablet rapidly disintegrating in the oral cavity. Chem Pharm Bull (Tokyo). 1996; 44: 2121-2127. 14.Babu CV, Kumar NR, Himasankar K, Seshasayana A, Murthy KV. Nimesulide -modified gum karya solid mixtures: Preparation, characterization and formulation development. Drug Dev ind Pharm 2003; 29:855-865. 15. Shirwaikar , Ramesh A. Fast disintegrating tablets of Atenolol by Dry Granulation method., IJPS. 2004; 66: 4, 422-426. 16. Mizumoto T, Masuda Y, Yamamoto T, Yonemochi E, TeradaK. Formulation design of a novel fast-disintegrating tablet. Int J Pharm. 2005; 306 (1): 83-90. 17. Jinichi, Asuka O, Yasuo Y, and Katsuhide T. Development of Fast Disintegrating Compressed Tablets Using Amino Acid as Disintegratation Accelerator: Evaluation of Wetting and Disintegration of Tablet. Chem. Pharm. Bull. 2005; 53(12): 1536-1539. 18. Rawas-Qalaji MM, Simons FER. Fast-disintegrating Sublingual Tablets: Effect of Epinephrine Load on Tablet Characteristics. AAPS Pharm Sci Tech. 2006; 7(2): 41. 19. Yoshio Kuno, Masazumi Kojima, Shuichi Ando and Hiroaki Nakagami. Evaluation of rapidly disintegrating tablets manufactured by phase transition of sugar alcohols, Journal of Controlled Release. 2005; 105:16-22. Table No 1: Formulae Of Pioglitazone Fast Dissolving Tablet Formulation F1 F2 F3 F4 F5 F6 F7 F8 F9 Ingredients (mg) (mg) (mg) (mg) (mg) (mg) (mg) (mg) (mg) Pioglitazone 30 30 30 30 30 30 30 30 30 4 8 12 4 8 12 4 8 12 - - - 5 5 5 10 10 10 120 120 120 120 120 120 120 120 120 80 76 72 75 71 67 70 66 62 2 2 2 2 2 2 2 2 2 4 4 4 4 4 4 4 4 4 Croscarmellose sodium Crospovidone Microcrystalline Cellulose D-Mannitol Magnesium stearate Talc Table No 2: Evaluation Of Fast Dissolving Tablets OfPioglitazone Hydrochloride Parameter F1 F2 F3 F4 F5 F6 F7 F8 F9 0.375 0.416 0.357 0.394 0.416 0.340 0.441 0.375 0.312 0.441 0.576 0.468 0.625 0.535 0.468 0.535 0.500 0.394 1.1176 1.384 1.310 1.750 1.286 1.206 1.213 1.333 1.055 14.96 27.70 23.71 36.96 22.24 16.35 17.57 25.00 5.28 25.35 23.44 25.42 26.43 23.33 20.19 26.53 23.43 26.31 4.1 4.1 4.3 4.2 4.3 4.9 4.6 4.7 4.9 71 69 68 66 62 51 61 60 59 Friability (%) 0.190 0.199 0.227 0.249 0.282 0.129 0.321 0.324 0.327 Weight 220 240 250 230 220 240 230 250 230 variation ±20 ±10 ±10 ±10 ±10 ±10 ±10 ±10 ±10 48 47 46 43 40 31 36 38 34 Bulk density (g/cm3) Tapped density (g/cm3) Hausner’s Ratio Compressibility Index Angle of Repose Hardness (kg/cm2) Disintegration time (sec) Wetting time (sec)