appendix a – examples of industrial lift trucks

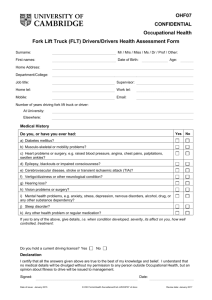

advertisement