Irom separation from iron bearing polymetal chloride solutions by

advertisement

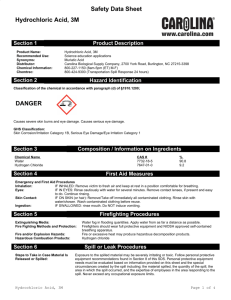

IRON SEPARATION FROM IRON BEARING POLYMETAL CHLORIDE SOLUTIONS BY MEANS OF HYDROLYSIS AND CRYSTALLIZATION B. Nowak, M. Österreicher, J. Pamminger, R. Stastny, H. Weissenbaeck SMS Siemag Process Technologies, Daffingerstraße 4, 1030 Vienna, Austria ABSTRACT The producer of certain metals like Nickel and Cobalt increasingly face a shortage of easy-to-mine and easy-to-process ore bodies. Their focus is shifting towards alternative raw materials which in turns demand new, different extraction techniques. One potential route for processing a ferrous ore with a non-ferrous target metal is atmospheric leaching with hydrochloric acid, and subsequent separate extraction from the pregnant leach solution (PLS). For the separation of iron from the PLS, and, in turns, the extraction of the non-ferrous compounds, the following flow sheet is proposed: Preconcentration of the PLS, oxidation of ferrous (if present) to ferric chloride, hydrolysis of ferric chloride leading to the precipitation of hematite and evaporation of hydrochloric acid, followed by crystallization of non-hydrolysable metal chlorides by means of sparging hydrogen chloride into the solution. Hydrogen chloride required in the latter step is produced internally by super-azeotropic distillation of regenerated hydrochloric acid. The liquid filtrate from the crystallization step is recycled to hydrolysis. Depending on the specific composition of the PLS, the hematite produced contains only traces of other impurities (typically < 1 wt%), whereas the crystallized mix of non-hydrolysable metal chlorides containing also the target metal in enriched form - contains ferric chloride only in an amount referring to the filter cake moisture (order of magnitude: 1 wt%). The iron-free crystals can then undergo further hydrometallurgical separation and extraction processes. As example, this flow sheet is proposed for treating nickel laterite ores. Experiments related to the demonstration of crucial assumptions of the flow sheet are presented. Based on those experiments a mass and energy balance of the flow sheet is estimated and presented together with a table of the major consumables in order to provide a basis for an estimation of operating cost and process economics. KEYWORDS Iron Chloride, Hydrolysis, Nickel Laterite, Hydrochloric acid