unit VIII power transmission Notes

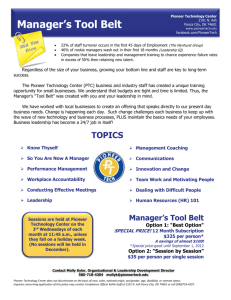

advertisement

Page 1 of 8 Elements of Mechanical Engineering 2. Power Transmission Rotating elements posses mechanical energy. This can be converted and utilised at the required place by transmitting. The rotating motion or power from prime mover to a machine or from one shaft to other may be transmitted by belts, ropes, chains and gears. Belts and ropes are used when the two shafts are at a long distance apart. Chains and gears are used when the shafts are at a small distance apart. TRANSMISSION SYSTEM Definition: The system that is used to transmit power from one mechanical element to another mechanical element is known as a transmission system or drive. Types of transmission systems. Various types of transmission systems used in practice are, (i) Belt drive (ii) Rope drive (iii) Chain drive and (iv) Gear drive (Note: Only belt and gear drives are discussed from syllabus point of view). Factors to be considered to select a transmission system To select a suitable transmission system (e.g. either belt or chain drive) the following key factors are to be considered. a) Distance between driver and driven pulley shaft b) Operational speed and c) Power to be transmitted BELT DRIVE It is one of the most effective method of transmitting power from one mechanical element to another mechanical element, by using belt as transmission system. 3. Figure 1: Belt drive As shown in figure 1 it consists of driver pulley and driven pulley which are connected by an endless belt. The belt encircles both the pulleys. Due to the frictional grip that exists between the belt and the pulley surface, power transmission takes place. Terminology of a belt drive Driver, driven, tight side, slack side and arc of contact are the key terms of a belt drive. They are shown in figure 2. SSE, MUKKA Page 2 of 8 Elements of Mechanical Engineering Figure 2 Terminology of a belt drive Driver: In a transmission system, the one which drives or which supplies power to another mechanical element is known as driver. Driven: In a transmission system the one which follows the driver or which receives power from the driver is termed as driven or follower. Tight side: The portion/side of the belt where there is maximum tension is called tight side. It is demoted by T1 and is expressed is newtons. Slack side: The portion/side of the belt where there is minimum tension is called slack side. It is denoted by T2 and is expressed in newtons. Arc /angle of contact: It is the portion of belt which is in contact with the pulley surface. In figure 2. it is shown by 'θ' and usually measured in degrees. Belt materials The materials used for belts must be strong, flexible and durable. It should have high coefficient of friction. Depending upon the season or conditions at work place i.e., whether dry or wet different materials should be chosen in manufacturing belts. The important materials commonly used in the manufacturing of belts are, (i) Rubber (ii) Leather (iii) Canvas (iv) Cotton (v) Balata (vi) Steel CLASSIFICATION There are mainly two types of belt drives namely, (i) Open belt drive and (ii) Cross belt drive Open belt drive The arrangement of open belt drive is shown in figure 3. Both driver and driven pulleys rotate in the same direction. Belt is passed over driver and driven. The driver pulley pulls the belt from one side and delivers it to the other side. For this reason, the tension in the pull (lower) side of the belt is more than that in the delivering side (upper). The lower side belt, because of more tension is known as tight side. The upper side because of less tension is known as slack side. SSE, MUKKA Page 3 of 8 Elements of Mechanical Engineering SSE, MUKKA Page 4 of 8 Elements of Mechanical Engineering Cross belt drive The arrangement of cross belt drive is shown in figure 4. Driven (follower) rotates in opposite direction to that of driver. The upper side (MQ) is slack side and the lower side. (NP) is tight side in the arrangement shown. At a point (P) where the belt crosses, it rubs against each other and there will be excessive wear and tear. In order to avoid this, the shaft should be placed at a maximum distance of 20b, where b is the width of belt and the speed of the belt should be less than 15m/s. Figure 4: Cross belt drive Comparison between open belt drive and cross belt drive. Open belt drive 1. Both driver and driven rotates in the Driver and driven rotates in the opposite same direction. 4. Requires less length of the belt compared Requires more length of belt compared to to crossed belt drive for same centre open belt drive for same centre distance, distance, ulle diameters. Cross belt drive uces. ulle diameters. 5. APPLICATIONS OF BELT DRIVE The belt drives are used to transmit power from one shaft to another by means of pulleys. Belt drive is one of the most common and effective method of transmitting power between two parallel shafts. Belt drive is used to transmit power. (i) From prime mover to any device and (ii) When the center distance is moderate In machine tools like lathe, drilling machine and in flour mills we can find that, the transmission of power/motion from one shaft to another by means of belt drives. SSE, MUKKA Page 5 of 8 Elements of Mechanical Engineering 4. Centrifugal tension As the belt continuously runs over the pulleys, some centrifugal tension is caused, whose effect will increase the tension on both the tight as well as the slack sides. When centrifugal tension is taken into account, then total tension in the tight side and slack sides are Tt1=T1+Tc Tt2 = T2 + Tc where, Tc is the centrifugal tension = mv2 m - mass of belt per unit length (kg/m) v -linear velocity of belt (m/s). For maximum power transmission, 1/3of the maximum tension (T1) will be absorbed as centrifugal tension. DEFINITIONS Slip A common phenomenon encountered in belt drives is the slipping of belt. Slip may be defined as the sliding of the belt from the pulley surface. It is the relative motion between pulley and the belt passing over it. It is generally expressed as a percentage (s). Following are the reasons for slip. 1. Low Coefficient of friction between belt and pulley surface 2. Smaller angle of contact. Creep The material of the belt is usually elastic in nature. It will be subjected to contraction and elongation during its use. When the belt is in continuous movement between driver and driven pulleys, it will be subjected to alternate tensions (T1 to T2 and T2 to T1). Compared to contraction, elongation will be more. Due to this, the length of the belt slightly increases with the passage of time. This causes relative motion and the phenomenon is called as creep. Note: Slip and creep are undesired factors as they reduce velocity ratio, in turn power transmission. Velocity ratio The velocity -ratio of a belt drive is defined as the ratio of the speed of the driven pulley to the speed of the driving pulley (or) The ratio of diameter of driving pulley to the diameter of driven Pulley. Equation for velocity ratio. Let d1 and d2 be the diameters of the driving and the driven pulleys respectively and N1 and N2 be their speeds in revolutions per minute (rpm) for a flat belt drive. Assuming that there is no slip between the belt and pulley surface, the linear speed of the belt over the two pulleys must be the same. [Π d1 N1] = [Π d2 N2] SSE, MUKKA Page 6 of 8 Elements of Mechanical Engineering d1 N 1 = d 2 N 2 Velocity ratio, N2/N1 = d1/d2 = = 𝐬𝐩𝐞𝐞𝐝 𝐨𝐟 𝐭𝐡𝐞 𝐝𝐫𝐢𝐯𝐞𝐧 𝐩𝐮𝐥𝐥𝐞𝐲 𝐬𝐩𝐞𝐞𝐝 𝐨𝐟 𝐭𝐡𝐞 𝐝𝐫𝐢𝐯𝐢𝐧𝐠 𝐩𝐮𝐥𝐥𝐞𝐲 𝐃𝐢𝐚𝐦𝐞𝐭𝐞𝐫 𝐨𝐟 𝐭𝐡𝐞 𝐝𝐫𝐢𝐯𝐢𝐧𝐠 𝐩𝐮𝐥𝐥𝐞𝐲 𝐃𝐢𝐚𝐦𝐞𝐭𝐞𝐫 𝐨𝐟 𝐭𝐡𝐞 𝐝𝐫𝐢𝐯𝐞𝐧 𝐩𝐮𝐥𝐥𝐞𝐲 From the above equation we can notice that, diameter, speed of a pulley are inversely proportional to each other. Note: When thickness of belt 't' is considered the velocity ratio is given by, (i) VR = N2/N1 = dl+ t/d2 + t (ii) When slip of the drive (s) is considered the velocity ratio is given by (iii) When both slip and thickness are considered VR = 𝑵𝟐 𝑵𝟏 = 𝒅𝟏+𝒕 𝒅𝟐+𝒕 𝑺 (𝟏 − 𝟏𝟎𝟎) Types of Pulleys Pulley is a rotating element/ member which is be mounted on a shaft. Depending upon the application, pulleys are classified as, (i) Stepped cone pulley or speed cone (ii) Jockey pulley and (iii) Fast and Loose pulley. 5. Stepped Pulley: It is also known as speed cone/cone pulley. In practice it may be required to operate the driven (follower) with different speeds say N1, N2. For example, in case of lathe, drilling machine it requires different speeds of followers depending upon the operation to be performed. This is possible if the driven pulley has different steps on it. As we know that diameter of the pulley (d) is inversely proportional to speed (N), it is possible to obtain different speeds due to different steps of diameters. Thus, stepped pulley is an integral casting of two or more number of pulleys of different sizes one adjacent to another as shown in figure 5. Figure 5: Stepped pulley 1, 2 are the steps on driving shaft pulley, A and B are the steps on driven shaft pulley. An endless belt is provided encircling one step on driver pulley and one step on driven pulley. To have the same length of SSE, MUKKA Page 7 of 8 Elements of Mechanical Engineering belt it should encircle the step which is smaller on one side and the step which is bigger on another side. Jockey pulley It is also called as Idler pulley/Rider pulley. Whenever centre distance is very less or when one of the pulley has very small arc of contact the power transmission will decrease. To increase the arc of contact (thereby power transmission can be increased) sometimes an Idler pulley will be introduced on the slack side of the belt near to the driven, as shown figure 6 which is called jockey pulley. Due to it's dead (self) weight the belt sags and hence, arc of contact will increase. Figure 6. Jockey Pulley ( Idler Pulley) Fast and Loose pulley: A fast and loose pulley drive as shown in figure 7, is used when the driven shaft is to be stopped whenever it is required without stopping the driving shaft. A pulley which is keyed to the machine shaft is called fast pulley and runs at the same speed as that of the main/main shaft. A loose pulley runs freely over the machine shaft without transmitting any power. When the driven shaft is required to be stopped, the belt is pushed on to the loose pulley by means of sliding bar having belt forks. Figure.7: Fast and loose pulley ADVANTAGES AND DISADVANTAGES OF FLAT BELT DRIVE Advantages (i) Running and maintenance cost is low. (ii) Possibility to transmit power over a moderately long distance. (iii) Efficient at high speeds. Disadvantages (i) Not a positive drive (due to slip) (ii) Not preferred for short center distance (iii) Belt joints reduces the life of the belt. (iv) Loss of power due to slip and creep. 7. 6. V-Belt Drive SSE, MUKKA Page 8 of 8 Elements of Mechanical Engineering These are widely used in power transmission. The belt which is having trapezoidal section is fitted into V-groove pulley. When the centre distance is less the power transmission can be increased by operating several belts side by side. Wide range of power transmission. (0.5kW - 150 kW) is possible by this drive. The cross section of a V - belt is shown in figure 8. Advantages (i) The drive is positive, because the slip between the belt and the pulley groove is negli- gible. (ii) More suitable for transmission of power for short center distance. (iii) There is no joints problem as the drive is of endless. (iv) Compact and gives high velocity ratio. (v) Can be easily installed and removed. Disadvantages (i) The V-belt drive cannot be used for large centre distances. (ii) Initial cost is more as it requires V-grooves on the pulley. (iii) Durability of V-belts is less compared to flat belts SSE, MUKKA