0439

advertisement

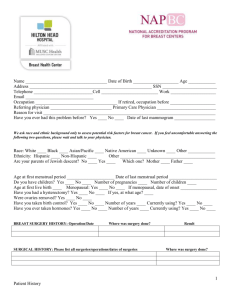

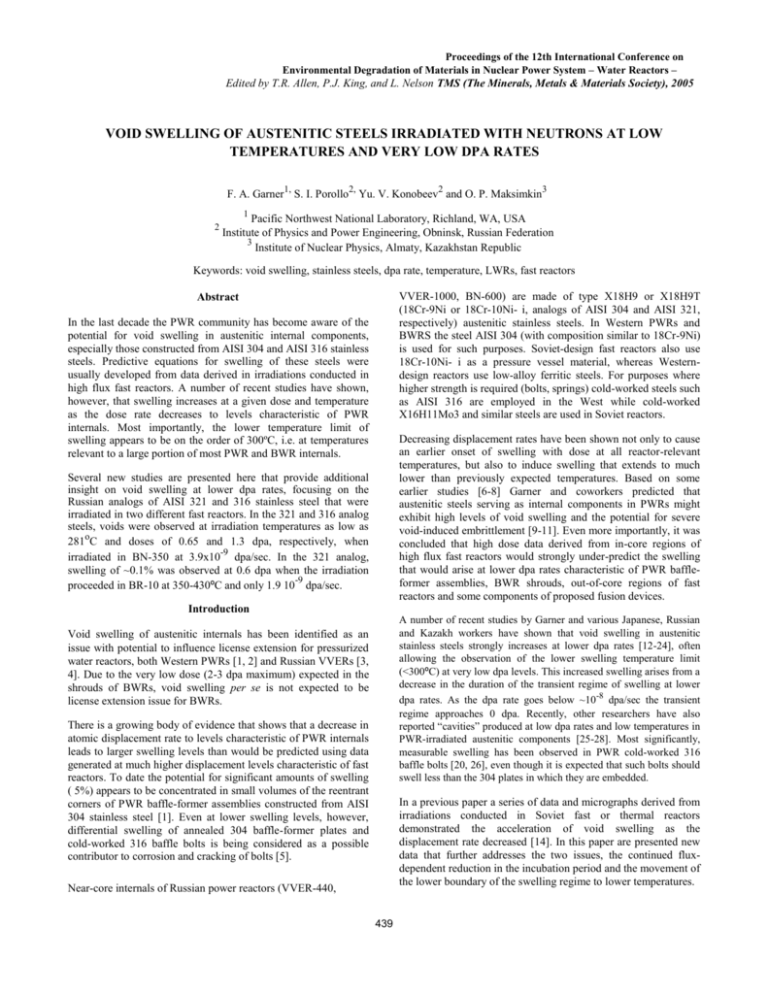

Proceedings of the 12th International Conference on Environmental Degradation of Materials in Nuclear Power System – Water Reactors – Edited by T.R. Allen, P.J. King, and L. Nelson TMS (The Minerals, Metals & Materials Society), 2005 VOID SWELLING OF AUSTENITIC STEELS IRRADIATED WITH NEUTRONS AT LOW TEMPERATURES AND VERY LOW DPA RATES 1, 2, 2 F. A. Garner S. I. Porollo Yu. V. Konobeev and O. P. Maksimkin 3 1 2 Pacific Northwest National Laboratory, Richland, WA, USA Institute of Physics and Power Engineering, Obninsk, Russian Federation 3 Institute of Nuclear Physics, Almaty, Kazakhstan Republic Keywords: void swelling, stainless steels, dpa rate, temperature, LWRs, fast reactors VVER-1000, BN-600) are made of type X18H9 or X18H9T (18Cr-9Ni or 18Cr-10Ni- i, analogs of AISI 304 and AISI 321, respectively) austenitic stainless steels. In Western PWRs and BWRS the steel AISI 304 (with composition similar to 18Cr-9Ni) is used for such purposes. Soviet-design fast reactors also use 18Cr-10Ni- i as a pressure vessel material, whereas Westerndesign reactors use low-alloy ferritic steels. For purposes where higher strength is required (bolts, springs) cold-worked steels such as AISI 316 are employed in the West while cold-worked X16H11Mo3 and similar steels are used in Soviet reactors. Abstract In the last decade the PWR community has become aware of the potential for void swelling in austenitic internal components, especially those constructed from AISI 304 and AISI 316 stainless steels. Predictive equations for swelling of these steels were usually developed from data derived in irradiations conducted in high flux fast reactors. A number of recent studies have shown, however, that swelling increases at a given dose and temperature as the dose rate decreases to levels characteristic of PWR internals. Most importantly, the lower temperature limit of swelling appears to be on the order of 300ºC, i.e. at temperatures relevant to a large portion of most PWR and BWR internals. Decreasing displacement rates have been shown not only to cause an earlier onset of swelling with dose at all reactor-relevant temperatures, but also to induce swelling that extends to much lower than previously expected temperatures. Based on some earlier studies [6-8] Garner and coworkers predicted that austenitic steels serving as internal components in PWRs might exhibit high levels of void swelling and the potential for severe void-induced embrittlement [9-11]. Even more importantly, it was concluded that high dose data derived from in-core regions of high flux fast reactors would strongly under-predict the swelling that would arise at lower dpa rates characteristic of PWR baffleformer assemblies, BWR shrouds, out-of-core regions of fast reactors and some components of proposed fusion devices. Several new studies are presented here that provide additional insight on void swelling at lower dpa rates, focusing on the Russian analogs of AISI 321 and 316 stainless steel that were irradiated in two different fast reactors. In the 321 and 316 analog steels, voids were observed at irradiation temperatures as low as o 281 C and doses of 0.65 and 1.3 dpa, respectively, when -9 irradiated in BN-350 at 3.9x10 dpa/sec. In the 321 analog, swelling of ~0.1% was observed at 0.6 dpa when the irradiation -9 proceeded in BR-10 at 350-430ºC and only 1.9 10 dpa/sec. Introduction A number of recent studies by Garner and various Japanese, Russian and Kazakh workers have shown that void swelling in austenitic stainless steels strongly increases at lower dpa rates [12-24], often allowing the observation of the lower swelling temperature limit (<300ºC) at very low dpa levels. This increased swelling arises from a decrease in the duration of the transient regime of swelling at lower dpa rates. As the dpa rate goes below ~10 -8 dpa/sec the transient regime approaches 0 dpa. Recently, other researchers have also reported “cavities” produced at low dpa rates and low temperatures in PWR-irradiated austenitic components [25-28]. Most significantly, measurable swelling has been observed in PWR cold-worked 316 baffle bolts [20, 26], even though it is expected that such bolts should swell less than the 304 plates in which they are embedded. Void swelling of austenitic internals has been identified as an issue with potential to influence license extension for pressurized water reactors, both Western PWRs [1, 2] and Russian VVERs [3, 4]. Due to the very low dose (2-3 dpa maximum) expected in the shrouds of BWRs, void swelling per se is not expected to be license extension issue for BWRs. There is a growing body of evidence that shows that a decrease in atomic displacement rate to levels characteristic of PWR internals leads to larger swelling levels than would be predicted using data generated at much higher displacement levels characteristic of fast reactors. To date the potential for significant amounts of swelling ( 5%) appears to be concentrated in small volumes of the reentrant corners of PWR baffle-former assemblies constructed from AISI 304 stainless steel [1]. Even at lower swelling levels, however, differential swelling of annealed 304 baffle-former plates and cold-worked 316 baffle bolts is being considered as a possible contributor to corrosion and cracking of bolts [5]. In a previous paper a series of data and micrographs derived from irradiations conducted in Soviet fast or thermal reactors demonstrated the acceleration of void swelling as the displacement rate decreased [14]. In this paper are presented new data that further addresses the two issues, the continued fluxdependent reduction in the incubation period and the movement of the lower boundary of the swelling regime to lower temperatures. Near-core internals of Russian power reactors (VVER-440, 439 TABLE 1 Irradiation conditions for sections cut from the BR-10 reactor vessel Place of specimen cutting Distance from core midplane, mm Total neutron fluence, 10 26 n/m 2 Dose, dpa Average irradiation temperature, ° Dose rate, dpa/s Level of basket bottom. 425 0.35 0.64 350 1.9 10 Level of upper flange 1890 … … 80 ... -9 for 20 years at ~80ºC. Swelling of 12X18 9T pressure vessel of BR-10 fast reactor Using a remote milling machine, strips 10 mm 2 mm or 7 mm 2 mm were cut from the original sections in an axial direction. Then from these strips TEM specimens and flat specimens for measurements of short-term mechanical properties were prepared. The mechanical measurements are reported elsewhere [24]. The 12X18 9T austenitic stainless steel is sometimes used as a containment vessel for Soviet reactors that do not involve high pressurization. Examples are the BR-10, BOR-60 and BN-600 fast reactors. In these applications the displacement rates experienced by the steel are very low, even compared to the rates experienced by PWR internals. TEM specimens in the form of disks of 3 mm in diameter with a perforated central hole were prepared using a standard technique employing the two-jet-polishing “STRUERS” device. Microstructural investigations were performed at an accelerating voltage of 100 kV using a JEM-100CX electron microscope equipped with a lateral goniometer. Samples for investigation of microstructure were recently cut from the first vessel of the BR-10 fast reactor. This vessel was replaced by a new vessel in 1979. The first vessel was variable in width with a maximum outside diameter of 535 mm and a total length just over 4 m. At the location of fuel assemblies the vessel has the outside diameter of 366 mm and wall thickness of 7 mm. The vessel material is 12X18H9T austenitic stainless steel in the solution treated condition. The nominal chemical composition of the steel is (wt. %): 0.12; Si 0.8; Mn 2.0; Cr at 17-20; Ni at 8-11; Ti 0.8. The microstructure of the unirradiated steel at the upper flange elevation is shown in Figures 1 and 2. It is observed that the steel had the anticipated austenitic structure with a grain size of ~10-20 microns. Austenitic grains, in turn, are divided into subgrains by dislocation walls with sizes ranging from ~1 to 5 microns (Figure 13 -2 1). The average dislocation density is equal to (4-5) 10 m . In addition, twins, large TiC precipitates with mean diameter of 0.5 to 1 microns, and much smaller precipitates distributed uniformly and at much higher density within the grains (Figure 2) were observed. The diameter of the small precipitates ranges from 50 to 60 nm, 19 -3 with their concentration at ~3 10 m . An analysis of microdiffraction patterns obtained from these precipitates showed that these precipitates have the fcc-structure with the lattice parameter of 0.43 nm, identifying them also to be TiC carbides. The first vessel was in operation for 20 years (July 1959 till October 1979) during which the core was composed of three fuel phases, the first two with PuO2 fuel and the third with UC fuel. Each phase lasted ~7 years. The total reactor operation during this period was 3930 days or 2562.6 effective full power days. The total neutron fluence accumulated by the vessel at the core 26 2 midplane was 8.44 10 n/m corresponding to an exposure dose of 33.1 dpa (NRT). On its inner side the vessel was in contact with sodium coolant flowing from bottom to top, but on its outer side it was in contact with air contained in the gap between the vessel and a safety vessel. In the first and last fuel phases the inlet temperature of the vessel was 350ºC, but during the second cycle it was higher at 430 . The microstructure of the irradiated steel at the elevation of the basket bottom is shown in Figures 3 and 4. Even at the low dose of 0.64 dpa the microstructure has changed significantly, producing a nonuniform spatial distribution of dislocation loops (Figure 3) and voids (Figure 4). Frank dislocation loops with a mean diameter of 33 nm and mean concentration of 3 1021 m-3 are seen in extended cluster arrays (Figure 3). The size of such arrays coincides with the size of sub-grains observed in the unirradiated steel and thus it can be assumed that the dislocation loops formed preferentially on the dislocation walls separating the sub-grains. To study the microstructure cross-sectional specimens were cut from two elevations of the vessel. Irradiation conditions for these cross sections are shown in Table 1. One specimen was cut from the elevation corresponding to the bottom level of the fuel basket, in which the lower ends of fuel assemblies were located. Another specimen was cut at the elevation of the upper flange of the primary coolant circuit. This second specimen was effectively unirradiated but had been aged The spatial distribution of voids is also rather non-uniform. Large voids are located mainly in zones having high loop concentration, i.e. in the former dislocation walls (Figure 4). Smaller voids, however, are distributed nearly uniformly throughout the grain. 440 As measured by microscopy the swelling of the steel is 0.1 %, 20 with a mean void diameter of 11 nm and concentration of 6 10 -3 m . Precipitates observed in the irradiated steel were essentially identical to those in the unirradiated steel. One can compare in Figure 5 the swelling observed for the pressure vessel with that of wrappers and pin cladding of BR-10 fuel assemblies made from the same steel but irradiated in-core at -7 higher dpa rates on the order 1-3 x 10 dpa/sec. The data base on swelling of the steel was obtained from examination of wrappers and fuel pins of the BR-10 reactor when where the inlet sodium temperature was equal to 430 [14]. For this comparison only swelling data derived from bottom of the wrappers and claddings were selected to insure an essentially isothermal data set. The larger BR-10 in-core data base including these data will be presented in Figure 8. a) b) Figure 1 Microstructure of unirradiated 12 18 9 from the upper flange of the BR-10 vessel, aged at ~80ºC for 20 years. Figure 3 Dislocation loops in 12 18 9 steel irradiated to 0.6 dpa at 350/430/350ºC: ) general view, b) dislocation loop cluster along preexisting sub-grain boundaries. The 430ºC data for cladding and wrappers are shown as a function of dose in Figure 5 together with the single datum for the vessel. It is seen from Figure 5 that after the incubation dose of 4-7 dpa the swelling of the wrapper and cladding at ~430 is an approximately linear function of dose with the swelling rate of 0.08 to 0.13 %/dpa. In general, one would expect that the vessel specimen, which spent two-thirds of its life at 350ºC and only one-third at 430ºC, would swell less because of its average lower temperature, but the swelling of the vessel steel is higher than expected (~0.1 % at only 0.64 dpa) than one would anticipate based on the extrapolation of the 430ºC curve to 0.6 dpa. On the basis of this one non-isothermal comparison alone, a clear effect of lower dpa rate to accelerate the onset of swelling can not be conclusively demonstrated. When combined with larger data base on flux-affected swelling cited earlier, however, this comparison is consistent with the previously observed strong effect of dpa rate on void swelling in 300 series stainless steels. Figure 2 Dislocations and TiC-precipitates from the unirradiated upper flange specimen, aged at ~80ºC for 20 years. 441 reaching a maximum of 12.6 and 15.6 dpa at average maximum dpa rates of 3.8 to 4.9 10-8 dpa/sec averaged over their lifetime in reactor. The first duct was constructed from 12Cr18Ni10Ti stainless steel, a Soviet analog of AISI 321 steel, and was produced with the final thermal-mechanical treatment of the duct being 15-20% cold deformation followed by annealing at 800oC for 1 hour. The second duct was constructed from 08Cr16Ni11Mo3, a Soviet analog of AISI 316 stainless steel. It was also producedusing the thermal-mechanical treatmentmentioned above. The measured temperature at the bottom of each assembly was 280 oC and the calculated temperature at the top of the 321 analog assembly was 430oC and was 420ºC for the 316 analog assembly. Specimens were chosen for examination between elevations having LWR-relevant temperatures between 280 and 333ºC for the 321 analog. For the highest elevation location chosen for the 316 analog the calculated temperature was 365ºC. Due to the thinness of the duct wall, the internal temperature was not raised significantly by gamma heating. Thus, the temperature of the steel is expected to be within 1-2 ºC of the local coolant temperature. The temperatures were relatively constant through the irradiation with the calculational uncertainty very small at the lower end of the duct at 280 ºC, rising to perhaps ±5ºC at the highest temperature elevation examined, which was 365 ºC. a) At the BN-350 site specimens with 10 mm height and 50 mm width were cut from the duct walls at various locations. Subsequent reduction of these specimens was conducted in a hot cell at INP-Almaty for microstructural analysis and microhardness measurements. Plate-shape specimens with sizes of 5 6 mm were prepared for metallography investigations, microhardness measurements and hydrostatic weighing. To date only the microscopy examination has been completed. The examination technique involved transmission electron microscopy (TEM) using a JEM-100CX electron microscope operating at 100 keV. The density was measured using an immersion density technique employing a CEPN-770 electronic balance with methyl alcohol as the working liquid. Disks of 3 mm diameter for microscopy studies were prepared from 300 m sections cut from the mid-section of the duct face. Mechanical grinding and polishing with subsequent electrochemical polishing were used for final preparation of TEM disks. The irradiation conditions for specimens examined are shown in Table 2. b) Figure 4 Voids in 12 18 9 steel irradiated to 0.6 dpa at 350/430/350ºC: ) large voids on sub-grain boundaries, b) spatial distribution of smaller voids. Microscopy examination confirms the presence of void swelling of the 321 analog in the range 281 to 333ºC, as shown in Table 3 and Figure 6. Most significantly, it is seen that even at 0.65 dpa and 281ºC voids are clearly visible, adding additional support to the growing body of evidence that swelling extends down to unexpectedly low temperatures and low doses if the displacement rate is low enough. Note that there is essentially no uncertainty in this temperature, being defined by the inlet temperature. Similar swelling indications were observed in the 316 analog, as shown in Figure7 and Table 4. Note that once again void swelling was observed at temperatures as low as 281ºC at 1.3 dpa. Only at 280ºC and 0.25 dpa were voids not observed. Figure 5 Dependence of steel 12 18 9 swelling in BR-10 on dose and dose rate. Light circles are wrappers of fuel assemblies and fuel pin claddings at 430ºC, black circle is the reactor vessel at 350/430/350ºC. Displacement rates are shown for each data set. In general the swelling at near-comparable conditions was larger in the 321 analog compared to that in the 316 analog, is in general agreement with expectations, especially with respect to the different nickel content of the alloys. It is known that the swelling of 300 series stainless steels is a strong function of the nickel content, decreasing with increasing nickel content [6, 29, 30]. Void swelling of 321 and 316 analog steels following irradiation in the BN-350 fast reactor Two hexagonal blanket assemblies with faces 50 mm wide and 2 mm thick were irradiated in the reflector region of the BN-350 reactor, 442 443 0.1 m 65 nm 280ºC, 0.25 dpa 281ºC, 1.27 dpa 0.1 m 0.1 m 309ºC, 7.08 dpa 337ºC, 15.6 dpa Fig. 7 Microstructure of AISI 316 analog steel irradiated in the BN350 reactor. 0.1 m 365ºC, 6.03 dpa 444 swelling in austenitic steels, as demonstrated by the BR-10 data at -9 350-430 ºC and dpa rates on the order of 10 dpa/sec. When the -8 -9 dpa rate lies is in the range of 10 to10 dpa/sec it becomes easier to see that void swelling in austenitic steels exists over a temperature range that reaches lower temperatures (~280ºC) than previously expected, and occurs at doses that are very low, often at < 1 dpa. The specimens examined in this study were all irradiated in fast reactors where both helium generation and hydrogen generation and retention are much lower than in light water reactors [31, 32]. Therefore the formation of voids is occurring in BN-350 and BR10 under conditions that are less conducive to void nucleation and stabilization than found in both PWRs and BWRs. Therefore the results of these studies allow us to speculate that it might be even easier to form voids in LWR austenitic components, especially for very low dose rate conditions found far from the reactor core. Since the inlet temperatures of both BWRs and PWRS are in this range this implies that a low level of voids will probably be observed in BWR shrouds as well as in PWR baffle-former assemblies. While the swelling in PWRs may become high enough to be a potential license extension issue, the total swelling expected in a BWR should be small enough such that it will most likely not be designated as a life extension issue. Table 2a-- Dose and temperatures of specimens over the height of the hexagonal assembly for 12Cr18Ni10Ti Distance from midplane, mm -900 -375 0 +75 +375 12Cr18Ni10Ti Damage rate -8 (x10 dpa/sec) 0.12 1.36 2.3 2.34 1.35 Dose (dpa) 0.65 7.3 12.28 12.6 7.25 Temperature (°C) 281 294 313 318 333 Acknowledgements The Russian portion of this work was supported by the Russian Foundation for Basic Research under the Project # 04-02-17278. The Kazakh portion of this work was supported by the Ministry of Energy and Mineral Resources of the Republic of Kazakhstan, and under ISTC project number K-437. The US portion was jointly sponsored by the Materials Science Branch, Office of Basic Energy Sciences, and the Office of Fusion Energy, US Department of Energy. Table 2b-- Dose and temperatures of specimens over the height of the hexagonal assembly for 08Cr16Ni11Mo3 Distance from midplane, mm Dose (dpa) -1200 -900 -500 0 +500 0.25 1.27 7.08 15.6 6.03 The authors are indebted to Natalia A. Brikotnina of Interpreter and Translation Services for her assistance in the conduct and interpretation of these experiments, and for translation of original Russian texts into English. 08Cr16Ni11Mo3 Damage rate Temperature -8 (x10 dpa/sec) (°C) 0.08 0.39 2.2 4.85 1.87 280 281 309 337 365 References 1. Finally, it should be noted that most previous perceptions concerning the lower boundary of void swelling and the fluxdependence of the lower temperature limit of swelling were established using reactors with relatively high inlet temperatures, such as 350ºC in BR-10 and 365-370ºC in FFTF and EBR-II. As shown in Figure 8, when swelling data on the same steel are compiled from reactors with different inlet temperatures and from data derived from both fueled and unfueled zones, then the apparent lower limit of swelling moves toward the lowest inlet temperature. Thus the previously published BR-10 in-core data upon extrapolation imply that swelling ceases somewhere between 400 to 430ºC [14], but this is a misperception arising from the inlet temperature and the strong flux gradient near the bottom of the core. Swelling actually develops down to significantly lower temperatures, as seen in both the vessel specimen and especially in specimens taken from the reflector region of BN-350 with its lower inlet temperature of 280ºC [15]. 2. 3. 4. Conclusions In agreement with many previous studies it appears that decreasing rates of displacement rate lead to an earlier onset of 445 Tang, H. T. and Gilreath, J. D., “Aging Research and Management of PWR Vessel Internals”, Proc. Fontevraud 5, Contribution of Materials Investigation to the Resolution of Problems Encountered in Pressurized Water Reactors, 23-27 September, 2002, paper #19, on CD format, no page numbers. Bryne, S. T., Wilson I. and Shogan, R., “Microstructural Characterization on Baffle Bolts” Proc. Fontevraud 5, Contribution of Materials Investigation to the Resolution of Problems Encountered in Pressurized Water Reactors, 23-27 September, 2002, paper #96, on CD format, no page numbers. Troyanov, V.M., Likhachev, Yu.I., Khmelevsky, M.Ya. et al.., “Evaluation and Analysis of Thermo-mechanical Behavior of Internals of VVERs Taking into Account Irradiation Effects”, in Russian, Proceedings of 5th Russian conference on Reactor Materials Science,Dimitrovgrad, Russia, 8-12 September 1997, Vol.2, Part I, pp. 3-18. Neustroev, V.S., Golovanov, V.N., Shamardin, V.K., Ostrovsky, Z.E., and Pecherin, . ., “Irradiation Phenomena in 18 10 Steel Irradiated in Different Reactors under Conditions Relevant to Operation Conditions of Internals of VVERs”, Proceedings of 6th Russian conference on Reactor Materials Science, Dimitrovgrad, Russia, 11-15 September 2000, Vol..3, Part I, pp. 3-23. Distance from midplane, mm Table 3 Microstructural data on cavities for irradiated stainless steel 12Cr18Ni10Ti Range for void Mean void Peak void diameter, Void density, 15 -3 sizes, nm diameter, nm 10 cm Swelling, nm % -900 <5-12 7.7 <5nm / 5-10 0.84 0.03 -375 <10 - 15 11.6 10 0.47 0.05 0 <10 - 20 11.2 10 2.9 0.25 +75 <8 -18 9.0 8 8.2 0.33 +375 <10 -35 15.3 15 1.0 0.23 Table 4. Microstructural data on cavities for irradiated stainless steel 08Cr16Ni11Mo3 Distance from midplane, Mm -1200 -900 Range for void sizes, nm <7 Mean void diameter, nm - -500 0 +500 10 -15 4 -15 10 -35 10.0 8.6 14.0 Peak void diameter, Void density, 15 -3 nm 10 cm - 8.0 10.0 10.0 no voids Some scattered voids 0.61 2.57 0.78 Swelling, % - 0.04 0.13 0.16 BR-10 in-core data BN-350 reflector BR-10 vessel Figure 8 Comparison of swelling data on annealed austenitic steel 18Cr-10Ni- i derived from three separate sources in two fast reactors [14-15]. The BR-10 data shown at 430ºC was presented earlier in Fig. 5. The added datum of the BR-10 vessel is shown at 350ºC only for convenience. 446 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. of Materials in Nuclear Power Systems – Water Reactors, 2003, pp. 647-656. 15. Porollo, S. I., Konobeev, Yu. V., Dvoriashin, A. M., Krigan, V. M. and Garner, F.A., “Determination of the Lower Temperature Limit of Void Swelling of Stainless Steels at PWR-relevant Displacement Rates”, 10th Int. Conf. on Environmental Degradation of Materials in Nuclear Power Systems – Water Reactors, August 5-9, 2001, issued in CD format, no page numbers. Simonen, E. P., Garner, F. A. and Klymyshyn, N. A. and M. B. Toloczko, “Response of PWR Baffle Bolt Loading to Swelling, Irradiation Creep and Bolt Replacement as Revealed Using Finite Element Modeling”, in this symposium. Garner, F. A., Chapter 6: "Irradiation Performance of Cladding and Structural Steels in Liquid Metal Reactors," Vol. 10A of Materials Science and Technology: A Comprehensive Treatment, VCH Publishers, 1994, pp. 419-543. Porter, D.L., and Garner, F.A ,“Swelling of AISI Type 304L Stainless Steel in Response to Simultaneous Variation in Stress and Displacement Rate”, Effects of Radiation on Materials: Twelfth International Symposium, ASTM STP 870, F.A Garner and J.S. Perrin, Eds., American Society for Testing and Materials, Philadelphia, 1985, pp.212-220. Seran, J.L., and Dupouy, J.M., “The Swelling of Solution Annealed 316 Cladding in RAPSODIE and PHENIX,” Effects of Radiation on Materials: Eleventh Symposium, ASTM STP 782, H.R. Brager and J.R. Perrin, Eds., American Society for Testing and Materials, 1982, pp.5-16. Garner, F. A., Greenwood L. R., and Harrod, D. L., "Potential High Fluence Response of Pressure Vessel Internals Constructed from Austenitic Stainless Steels", Proc. Sixth Intern. Symp. on Environmental Degradation of Materials in Nuclear Power Systems Water Reactors, San Diego, CA. August 1-5, 1993, pp. 783-790. Garner, F. A., "Materials Issues Involving Austenitic Pressure Vessel Internals Arising From Void Swelling and Irradiation Creep", Trans. Am. Nucl. Soc., 71 (1994) 190. Garner, F. A. and Toloczko, M. B., "Irradiation Creep and Void Swelling of Austenitic Stainless Steels at Low Displacement Rates in Light Water Energy Systems", J. of Nucl. Mater. 251 (1997) 252-261. Garner, F. A., Edwards, D. J., Bruemmer, S. M., Porollo, S. I., Konobeev, Yu. V., Neustroev V. S., Shamardin, V. K. and Kozlov, A. V., "Recent Developments Concerning Potential Void Swelling of PWR Internals Constructed from Austenitic Stainless Steels", Proc. Fontevraud 5, Contribution of Materials Investigation to the Resolution of Problems Encountered in Pressurized Water Reactors, 23-27 September, 2002, paper #22, on CD format, no page numbers. Garner, F. A., Porollo, S. I., Vorobjev, A. N., Konobeev, Yu. V., Dvoriashin, A. M., Krigan, V. M., Budylkin, N. I. and Mironova, E. G., "Void-Induced Swelling and Embrittlement in the Russian Equivalent of AISI 316 Stainless Steel at PWR-Relevant End-ofLife Conditions", International Symposium on "Contribution of Materials Investigation to the Resolution of Problems Encountered in Pressurized Water Reactors, 14-18 Sept. 1998, Fontevraud, France, pp. 249-260. Garner, F. A., Budylkin, N. I., Konobeev, Yu. V., Porollo, S. I., Neustroev, V. S., Shamardin, V. K., and Kozlov, A. V. “The Influence of DPA rate on Void Swelling of Russian Austenitic Stainless Steels,” 11th International Conference on Environmental Degradation 16. Neustroev, V. S., Shamardin, V. K., Ostrovsky, Z. E., Pecherin, A. M. and Garner, F. A., “Temperature-Shift of Void Swelling Observed at PWR-Relevant Temperatures in Annealed Fe-18Cr-10Ni-Ti Stainless Steel Irradiated at High and Low Dpa Rates in BOR60", International Symposium on "Contribution of Materials Investigation to the Resolution of Problems Encountered in Pressurized Water Reactors, 14-18 Sept. 1998, Fontevraud, France, pp. 261-269. 17. Neustroev, V. S., Shamardin, V. K., Ostrovsky, Z. E., Pecherin, A. M., and Garner, F. A., "Temperature-Shift of Void Swelling Observed at PWR-Relevant Temperatures in Annealed Fe-18Cr-10Ni-Ti Stainless Steel Irradiated in the Reflector Region of BOR-60", Effects of Radiation on Materials: 19th International Symposium, ASTM STP 1366, M. L. Hamilton, A. S. Kumar, S. T. Rosinski and M. L. Grossbeck, Eds., American Society for Testing and Materials, pp. 792800 (2000). 18. Okita, T., Sato, T., Sekimura, N., Garner, F. A. and Greenwood, L. R., “The Primary Origin of Dose Rate effects on Microstructural Evolution of Austenitic Alloys during Neutron Irradiation”, Journal of Nuclear Materials 207-211 (2002) 322-326. 19. Okita, T., Sato, T., Sekimura N., Garner, F. A., and Wolfer, W. G. “ Combined Effect of Temperature, Displacement Rate and Composition on the NeutronInduced Swelling of Austenitic Alloys”, 11th International Conference on Environmental Degradation of Materials in Nuclear Power Systems – Water Reactors, August 2003, issued on CD format, no page numbers. 20. Edwards, D. J., Simonen, E. P., Garner, F. A., Oliver, B. A., and Bruemmer, S. M., “Sensitivity of Microstructural Evolution Due to Temperature and Dose Gradients in Neutron-Irradiated 316SS”, Journal of Nuclear Materials 317 (2003) 32-45. 21. Budylkin, N. I., Bulanova, T. M., Mironova, E. G., N. M. Mitrofanova, N. M., Porollo, S. I., Chernov, V. M., Shamardin, V. K. and Garner, F. A., “The Strong Influence of Displacement Rate on Void Swelling in Variants of Fe-16Cr-15Ni-3Mo Austenitic Stainless Steel Irradiated in BN-350 and BOR-60”, Journal of Nuclear Materials 329-333 (2004) 621-624. 22. Maksimkin, O. P., Tsai, K. V., Turubarova, L. G., Doronina, T., and Garner, F. A., “Characterization of 08Cr16Ni11Mo3 Stainless Steel Irradiated in the BN350 Reactor,” Journal of Nuclear Materials 329-333 (2004) 625-629. 23. Maksimkin, O. P., Tsai, K. V., Turubarova, L. G., Doronina, T., and Garner, F. A., “Void Swelling of AISI 321 Analog Stainless Steel Irradiated at Low dpa Rates in the BN-350 Reactor, submitted to Fusion Reactor 447 24. 25. 26. 27. 28. 29. 30. 31. 32. Materials Semiannual Progress Report, July 2005,: also to be submitted to ICFRM-12. Porollo, S. I., Dvoriashin, A. M., Konobeev, Yu. V., Ivanov, A. A., Shulepin, S. V. and Garner, F. A., “Microstructure and Mechanical Properties of Austenitic Stainless Steel 12X18H9T Irradiated in the Pressure Vessel of BR-10 at Very Low Displacement Rates”,submitted to J. Nuclear Materals: also submitted to Fusion Materials Semiannual Progress Report, July 2005. Fujii, K., Fukuya, K., Furutani, G., Torimaru, T., Kohyama A. and Katoh, Y., “Swelling in 316 Stainless Steel Irradiated in a PWR”, 10th Int. Conf. on Environmental Degradation of Materials in Nuclear Power Systems – Water Reactors, issued in CD format, no page numbers. Thomas, L. E. and Bruemmer, S. M., “Analytical Transmission Electron Microscopy Characterization of Stress Corrosion Cracks in an Irradiated Type 316 Stainless Steel Core Component”, Proc. Fontevraud 5, Contribution of Materials Investigation to the Resolution of Problems Encountered in Pressurized Water Reactors, 23-27 September, 2002, paper #60, on CD format, no page numbers. Edwards, D. J., Simonen, E. P., Bruemmer S. M, and Efsing, P.,”Microstructural Evolution in Neutron Irradiated Steel: Comparison of LWR and Fast-Reactor Irradiations,” in these proceedings. Fujimoto, K., Yonezawa , T., Wachi , E., Yamaguchi , Y., Nakano, M., , Shogan , R. P., Massoud , J. P. and Mager, T. R., “Effect of the Accelerated Irradiation and Nuclear Transmuted Gas on IASCC Characteristics for Highly Irradiated Austenitic Stainless Steels,” in these proceedings. F. A. Garner, "Recent Insights on the Swelling and Creep of Irradiated Austenitic Alloys," Invited Paper, J. of Nucl. Mater., 122 and 123, (1984), pp. 459-471. F. A. Garner and H. R. Brager, "Swelling of Austenitic Fe-Cr-Ni Ternary Alloys During Fast Neutron Irradiation," Effects of Radiation on Materials: Twelfth International Symposium, ASTM STP 870, F. A. Garner and J. S. Perrin, Eds., ASTM, Philadelphia, PA, 1985, pp. 187-201. F. A. Garner, B. M. Oliver, L. R. Greenwood, D. J. Edwards, S. M. Bruemmer and M. L. Grossbeck, “Generation and Retention of Helium and Hydrogen in Austenitic Steels Irradiated in a Variety of LWR and Test Reactor Spectral Environments”, 10th International Conference on Environmental Degradation of Materials in Nuclear Power Systems – Water Reactors, 2001, issued on CD format, no page numbers. F. A. Garner and L.R. Greenwood, “Survey of Recent Developments Concerning the Understanding of Radiation Effects on Stainless Steels Used in the LWR Power Industry,” 10th International Conference on Environmental Degradation of Materials in Nuclear Power Systems – Water Reactors, 2003, pp. 887-909. 448