UV Light Cleaning of Amputee Liners RAKES Inc. NCIIA Grant

advertisement

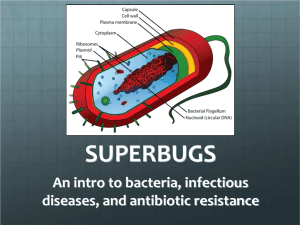

UV Light Cleaning of Amputee Liners RAKES Inc. NCIIA Grant Proposal 12/6/2012 Abstract Currently, cleaning gel liners is difficult and time consuming for amputees. The bacteria that colonize and grow in used gel liners cause infection and skin irritation for the product’s users. The bacteria also carry a distinct smell. These problems could be improved by thorough cleaning the liner. A commercially available product called the shUVee UV shoe deodorizer could hold a possible design solution. UV irradiation of bacteria that leads to their death can also result from the disruption of the folate biosynthesis pathway in which the production of various folate precursors does not occur. Folate is a primary metabolite produced by bacteria and is necessary in their growth and proliferation. Our goal is to use the precedent design of the deodorizer in order to create a cost-effective UV light cleaner for the amputee liners. Objectives: Test existing shUVee ultraviolet shoe deodorizer to determine if the UV light can act as a broadspectrum antibiotic agent in gel liners Design a new product that can provide similar sanitization effects for amputee gel liners to kill MRSA, strep and staph infections Refine the new product design to increase cost-efficiency to a level feasible for market Introduction Bacterial growth occurs in warm areas of the body that are not cleaned frequently. More specifically, there is a strong need associated with the sanitization of amputee gel liners that patients wear on their amputated limbs. Often times, fungal and bacterial infections develop due to inabilities to completely clean the gel. This is a widespread problem among amputees, especially those who are active athletically, as the sweat from their physical activity produces metabolites that are favorable for bacterial growth. As of now, there is no product on the market that specifically addresses this issue. Amputees simply clean the gel liners with sanitized paper towel, but this method has been ineffective at removing the odor produced by the bacteria. A precedent device exists for this purpose, as seen in Figure 1, which uses UV light to kill bacteria in shoes to remove the odor. Previous research has shown that UV light impairs bacterial growth, but the product cost is too high for feasibility. By interrupting the folate production and other metabolic byproducts of the bacteria colony, the radiation disrupts bacterial-friendly environment in the liner that enables further bacterial growth. Ideally, this process of design would include the improvement of the existing device to kill many different types of germs in a cost-effective manner. History & Context After reviewing the information provided by Mr. Fitzsimmons about the need for a gel liner sanitizer to disinfect patient’s prosthetics in light of the shUVee ultraviolet shoe deodorizer product and considering our project objectives, our team discussed possible solutions. The shUVee ultraviolet shoe deodorizer, manufactured by Kagan Unlimited, is a sanitary agent that is currently used to disinfect shoes. This product uses ultraviolet light to clean surfaces inside the shoes and effectively eliminates bacteria, fungus, and foul odors associated with their growth. Currently, a technology is not available in gel liners on prosthetics. Mr. Fitzsimmons is very interested in testing the advertising claims of the shUVee ultraviolet shoe deodorizer product and possibly applying this technology to a gel liner for prosthetic devices. Prior work by the National Environmental Services Center has shown that UV light can be used to kill bacteria in water to purify water. Studies have demonstrated the efficacy of using 405 and 470-nm wavelength blue light to kill MRSA. We hope to be able to show that UV light used in the shUVee apparatus can be used to kill bacteria, and hopefully be applied to the gel liners of amputees. If this project is successful, we hope to receive a patent for this work. We have a strong belief that this project will succeed because it has been shown that UV light can kill bacteria. Our main obstacle is designing a cost effective apparatus avaliable to be used on the market. Team The RAKES Team is composed of Evan Dalton, Aladine Elsmadicy, Ke Qin, Ryan Khodadadi, and Simon Yohannes. All team members will graduate in May of 2012 with a Bachelor of Engineering in Biomedical Engineering. In addition, Aladine will graduate with a degree in Mathematics and Evan will graduate with a degree in Economics. Aaron Fitzsimmons CP, OT of Nashville Prosthetics and Dr. Matthew Walker of Vanderbilt University will advise the team. This team has a wide range of experiences and relevant coursework that will be invaluable to the project and are listed below: Simon Yohannes has experience with AFM (Atomic Force Microscopy), which he used to study cooperation between promoters in phage DNA. He also has experience in building PDMS micro-fluidic channels, which are used for DNA tether experiments. His coursework background includes areas such as Tissue Engineering, Systems Physiology, Biomaterials, Biology, and Organic Chemistry. Ryan Khodadadi has done research involving the social amoeboid Dictyostelium discoideum, a model organism for eukaryotic systems biology, with the goal of elucidating G-protein signaling pathways involved in cAMP and folic acid-mediated chemotaxis. Relevant techniques stemming from this research experience such as axenic cell culture techniques and chemotaxis assays could be applied to this design project. Relevant coursework: Organic Chemistry, Therapeutic Bioengineering, Biology, Systems Physiology, Tissue Engineering, and Biomaterials. Kevin Qin has worked on various projects including elucidating cellular signaling pathways, design of microfluidic-based devices, and more recently, designing novel instrument systems for early detection of pathological states based on Raman spectroscopy data. Relevant coursework include Biology, Physiology, Biomaterials, and Therapeutic Engineering. Evan Dalton has experience in medical imaging through his work in the Vanderbilt Psychiatric Neuroimaging Program where he analyzed structural MRIs. He also plans to use his experiences at Deutsche Bank to form the team budget, and create presentations and organization strategies. His relevant coursework includes Tissue Engineering, Organic Chemistry, Systems Physiology, Biomaterials, Biomechanics, and Physiological Transport Phenomena. Aladine Elsamadicy as worked with tissue culture and antibodies. He has worked on projects in the area of proteomics. These techniques include western blots and electrophoresis. In addition, he has observed numerous surgical procedures at the Madison Surgery Center. Relevant coursework: Organic Chemistry, Tissue Engineering, Biomaterials, and Systems Physiology. Work plan & Outcomes RAKES Inc. hopes to have a successful prototype built and tested by the end of the grant period. Commercially, we expect to begin production of our design for trial usage by specific patients. Educationally, we hope to publish our findings detailing the clinical data from our prototype testing. In order to measure the efficacy of sanitization of our product we will perform several different experiments using bacterial cells, agar plates, and the optimal UV light frequency. First we will culture different types of bacterial cells, including the MRSA bacteria, on different agar plates. After colonizing the bacteria we will expose all of the plates with our UV light for approximately eight hours. After the exposure to UV light, we will count the number of bacterial cells that are alive and compare it to the original number we started with. We expect that the number of bacterial cells that are alive after exposure to UV light will be significantly less than the number of bacterial cells that are alive pre-exposure to UV light. Depending on the amount of living bacterial cells alive after exposure to UV light, we can quantify the efficacy of our sanitization using UV light. A more specific experiment will be using the MRSA bacterial cells, which are the most common bacterial cells in gel liners, and we will test the tolerance of the MRSA bacterial cells with multiple exposures to UV light. We tend to culture the MRSA bacterial cells in a cell agar plate, and then expose it to UV light for approximately eight hours. Similar to the experimental trials before, we will count the number of bacterial cells alive and then re-culture those cells and expose it to UV light again. After the second exposure, we will count the number of MRSA bacterial cells alive and compare it to the original number pre-exposure to UV light the second time. We will then continue these trials four more times to accurately create and exponential decay graph that will illustrate the tolerance of the MRSA bacterial cells over time. We expect that the MRSA bacterial cells will not gain tolerance to the UV radiation until after several hundred exposures. This experiment using MRSA bacterial cells, along with the first experiment using different types of bacterial cells, will quantify the efficacy of the sanitization of our product. The design that we are going to incorporate will be variations of the shUVee liner products. We plan to create a single platform for the prosthetic gel liner instead of two. We decided to go with this design to insure the efficiency of our product and not creating extra costs when it’s not needed, because most amputees only have single limb prosthetics. Next, we are moving away from the pressure sensor switch, used in the shUVee liner products, but a toggle switch to allow for patients to turn on and off UV radiation. We are making a device that will be already assembled, and will be portable by just unplugging the device from the electrical socket. Lastly, we will add base grip pads on the bottom of our device to allow for a stable foundation on any smooth surface. Finally, this solution must be cost-efficient to a level feasible to enter the market. Keeping low cost in mind in the design, we will be using a plastic material for the framework of our device. We will also find electrical components and a UV light at a low cost to alleviate the total cost for the manufacturer and ultimately the consumers. Evaluation and Sustainability Plan The project will be considered successful if UV light effectively cleans amputee liners. This includes testing existing shUVee ultraviolet shoe deodorizer to determine if the UV light can act as a broad-spectrum antibiotic agent in gel liners and designing a new product that can provide similar sanitization effects for amputee gel liners. Following the end of the grant period, a subsequent Senior Design team potentially will continue the project. Figures: Figure 1. The ShUVee liner our project will strive to emulate. Figure 2. The ShUVee legacy device. Résumés: Résumés can be found in the folder entitled ‘Resumes’ that was attached to this document. Appendix A: Gantt Chart Appendix B – Budget Expenses Petri Dishes Glucose Proteose Peptone Yeast Extract Anhydrous MgSO4 KH2PO4 K2HPO4 Prototyping Total Cost (USD) Justification Agar plates for bacteria culture 244 145 318 25 137 132 65 2000 $1500 for 3 gel liner UV prototypes; $500 for redesign $3,066