INSTRUCTIONS TO AUTHORS FOR THE PREPARATION

advertisement

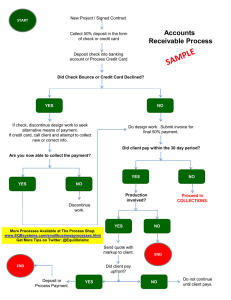

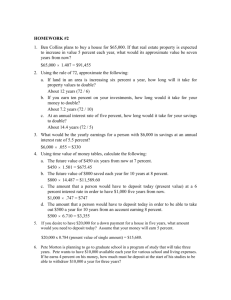

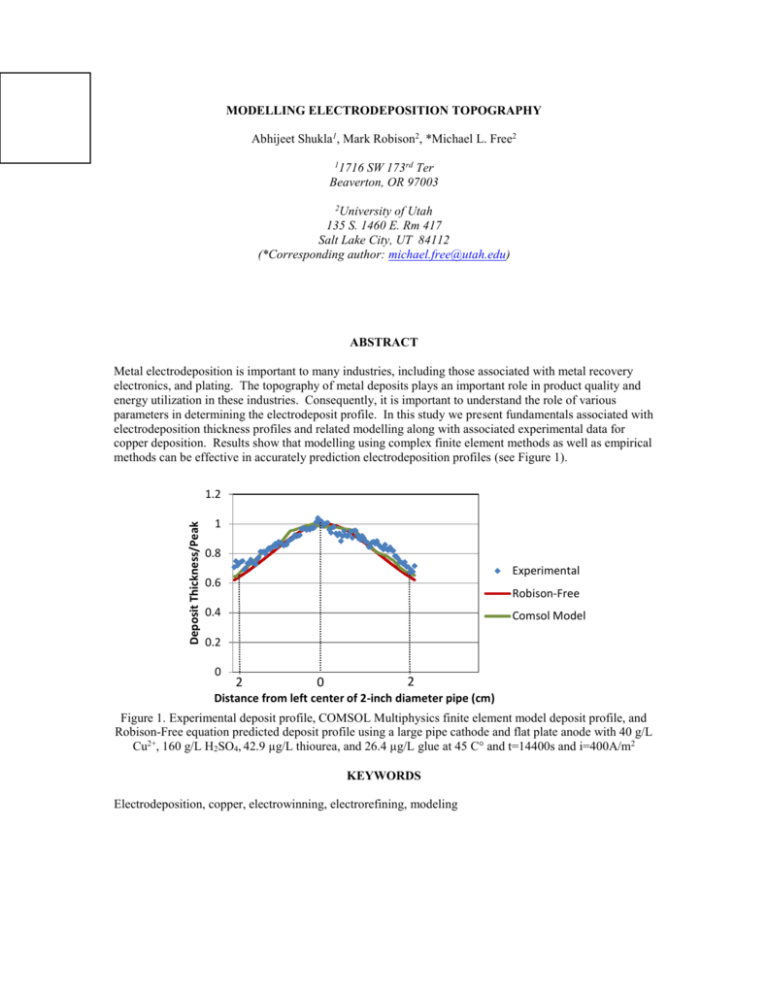

MODELLING ELECTRODEPOSITION TOPOGRAPHY Abhijeet Shukla1, Mark Robison2, *Michael L. Free2 1 1716 SW 173rd Ter Beaverton, OR 97003 2 University of Utah 135 S. 1460 E. Rm 417 Salt Lake City, UT 84112 (*Corresponding author: michael.free@utah.edu) ABSTRACT Metal electrodeposition is important to many industries, including those associated with metal recovery electronics, and plating. The topography of metal deposits plays an important role in product quality and energy utilization in these industries. Consequently, it is important to understand the role of various parameters in determining the electrodeposit profile. In this study we present fundamentals associated with electrodeposition thickness profiles and related modelling along with associated experimental data for copper deposition. Results show that modelling using complex finite element methods as well as empirical methods can be effective in accurately prediction electrodeposition profiles (see Figure 1). Deposit Thickness/Peak 1.2 1 0.8 Experimental 0.6 Robison-Free 0.4 Comsol Model 0.2 0 2 0 2 Distance from left center of 2-inch diameter pipe (cm) Figure 1. Experimental deposit profile, COMSOL Multiphysics finite element model deposit profile, and Robison-Free equation predicted deposit profile using a large pipe cathode and flat plate anode with 40 g/L Cu2+, 160 g/L H2SO4, 42.9 µg/L thiourea, and 26.4 µg/L glue at 45 C° and t=14400s and i=400A/m2 KEYWORDS Electrodeposition, copper, electrowinning, electrorefining, modeling