Appendix C - Regional Technical Forum

advertisement

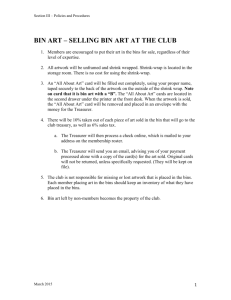

Appendix C – EM&V and UES Calibration Plan EM&V AND UES CALIBRATION PLAN: NIGHTCOVERS ON VERTICAL MEDIUM TEMPERATURE OPEN MULTI-DECK CASES (RETROFIT) Submitted to REGIONAL TECHNICAL FORUM Submitted by Portland Energy Conservation Inc. 100 SW Main St, Ste 1600 Portland, OR 97204 August 19, 2011 TABLE OF CONTENTS 1. OVERVIEW.......................................................................................................... 1 2. ELIGIBLE PROJECTS ............................................................................................... 1 3. REQUIRED COMMISSIONING .......................................... ERROR! BOOKMARK NOT DEFINED. 4. DATA COLLECTION REQUIREMENTS ........................................................................... 1 4.1. Refrigeration system Specifications ................................................................................... 1 4.2. HVAC Operations ............................................................................................................... 2 4.3. Pre and Post-Period Electrical Measurements .................................................................. 2 4.4. Facility Control System Pre and Post-Period Trend Logs ................................................... 3 5. SAVINGS ESTIMATION STEPS ................................................................................... 3 5.1. Compute Savings for Trend Log Intervals .......................................................................... 3 5.2. Annualized Savings: System Load Determined by OAT ..................................................... 3 6. SAMPLING PROCEDURE .......................................................................................... 3 7. RELATIONSHIP TO OTHER PROTOCOLS AND GUIDELINES ................................................. 4 8. TYPICAL COST OF APPLYING THIS PROTOCOL ............................................................... 4 Portland Energy Conservation Inc i 1. OVERVIEW This document summarizes the research that needs to be performed in order to calibrate the UES values provisionally approved by the Regional Technical Forum for the Grocery Refrigeration Measure: Night Covers on Vertical Medium Temperature Open Multi-deck Cases, (Retrofit) This document specifies minimum acceptable data collection requirements and the method by which these data are to be used to calibrate UES estimate. For some data elements, alternative sources of data, considered to be of superior quality, are also defined and are allowed. 2. ELIGIBLE PROJECTS Following criteria define the eligible night cover upgrade projects for the purpose of UES Calibration. This does not define the projects eligible for incentive; please see PECI’s grocery program Terms and Conditions for more general requirements. Measure must impact affected compressor loads by a minimum of 10%, based on engineering load calculation. Aside from measure and system upgrades directly caused by the measure under discussion, no other measures may be implemented during the pre or post monitoring period. Natural Gas usage data must be available via hourly pulse data for both the pre and post period. 3. DATA COLLECTION REQUIREMENTS The following data must be collected in order to affectively calibrate the UES estimate. The minimum acceptable procedure for obtaining the data is specified. In some cases, alternative procedures are allowed which would provide data of higher quality. 3.1. Refrigeration System Specifications Compressor Specs and Configuration. Determine by inspection or with current refrigeration schedule: Complete compressor model and serial numbers for all affected loads, suction temperature, minimum condensing pressure, refrigerant type. Condenser Specs. Determine by inspection or with current refrigeration schedule: Condenser model and serial number, capacity, control sequence, fan motor type and horsepower, minimum condensing temperature, design approach temperature. Baseline Control Strategy. Determine by inspection or with current refrigeration schedule: Compressor unloading strategy, system trending capability. Case Specs. Determine by inspection or with current refrigeration schedule: Capacity, defrost schedule, lighting power density, suction temperature, fan motor type. Portland Energy Conservation Inc 1 Heat Reclaim System Specs. (If applicable) 3.2. HVAC Operations HVAC System Setpoints. Obtained from inspection or facility operator. System schedule and temperature setpoints. HVAC System Specs. Identify from inspection: unit efficiency ratings (EER or SEER and AFUE where applicable), make and model numbers, and heating fuel type Economizer Setpoints. Obtained from inspection or facility operator. Determine if an economizer is present and operating. If applicable, identify the economizer changeover temperature. Weather Station. Identify the TMY (Typical Meteorological Year) weather station which is closest to the project site. 3.3. Pre and Post-Period Electrical Measurements One-Time Electrical Measurements. Taken by a licensed electrician under the on-site supervision of the practitioner. Log Voltage and amperage to ensure trend data is reasonable for all affected loads. True Power Trends for Compressor Rack or Affected Single Compressor. A data logger is installed to measure 15-minute averages of interval true RMS voltage, current, and power factor for 3-weeks pre and 3-weeks post measure installation and commissioning. True Power Trends for Condenser(s). A data logger is installed to measure 15-minute averages of interval true RMS voltage, current, and power factor for 3-weeks pre and 3-weeks post measure installation and commissioning. Hourly Natural Gas Meter Utility Pulse Data. 60-minute natural gas trends must be available by the local natural gas utility. A minimum of 3-weeks pre and post measure installation and commissioning are required. Depending on time of year and range of outdoor temperatures, more data may be needed to adequately identify natural gas savings. This will be identified by the practitioner before the start of the project. Amperage Trends for Affected Cases. A data logger is installed to measure 15-minute averages of case auxiliary load amperage (i.e. lights and evaporator fans). If trend loggers are not equipped to record average amperage, then a minimum logging interval of 5-minutes is required. 3-weeks pre and post measure commissioning are required. OAT Trends. 15-minute outside air temperature trends for 3-weeks pre and post measure commissioning. 2 Alternative Measurements. In lieu of the on- site OAT trends, applicable NOAA data can be utilized. Portland Energy Conservation Inc 3.4. Facility Control System Pre and Post-Period Trend Logs Trend Log of Suction Pressure or Temperature This data may be obtained from the facility’s control system. 4. SAVINGS ESTIMATION STEPS Savings are estimated using standard engineering calculations. The savings will be projected over a typical year using TMY3 data from an appropriate weather station. 4.1. Compute Savings for Trend Log Intervals Data Synchronization. Start times for all trend log intervals are synchronized by moving each to the closest standard interval starts times of 0, 15, 30 and 45 minutes after the start of each hour. 4.2. Annualized Savings: System Load Determined by OAT Average Savings by Trend Log Bin. Average kW savings by four degree temperature bins for all trend log intervals during operating hours, as defined by facility operations schedules. Operating Hours by TMY Bin. Divide the 8,760 TMY OAT data into two degree bins and compute frequency of annual operating hours for each bin, as defined by facility operations schedules. Average Savings by TMY Bin. TMY bin average bin savings equal trend log average bin savings for each matching bin. Extrapolate average savings for TMY bins that do not have trend log data. Higher temperature bins are extrapolated by a linear equation fit to the trend log bins above 60 degrees and lower temperature bins by a linear equation fit to the bins below 55 degrees. Saving by Bin. For each TMY bin, multiply the average bin savings by the number of operating hours in each bin, to get kWh savings in each bin. Annual Savings. Sum the kWh values across TMY bins. 5. SAMPLING PROCEDURE The sample of provisional UES projects should capture systems that are frequently implemented and/or produce significant program savings as well as a representative range of store and/or system conditions that users of the standard protocol expect to encounter. Load measures and system measures1 have different inputs and calculation methodologies; thus, the sample should contain a mix of these projects. Where available, data collection will include whole building interval meter data as well as refrigeration temperature and pressure trends from the store Energy Management System. (The EMS should be checked for accuracy.) These data will provide context for store operation during the monitoring period. Portland Energy Conservation Inc 3 Whole building interval meter data are available in PSE, EWEB, Seattle City Light and Tacoma service territory on a limited basis. Sample size will ideally and at minimum be based on an 80 percent confidence level, 20 percent precision, and a coefficient of variation (CV) of 0.5. It is estimated that 7-sites will need to be evaluated to calibrate the UES value. This quantity will be re-evaluated after 5-data sets have been collected and analyzed to ensure appropriate sample size. 6. RELATIONSHIP TO OTHER PROTOCOLS AND GUIDELINES The relationship between this protocol and other relevant protocols and guidelines is as follows: International Performance Measurement and Verification Protocol – 2007 (IPMVP), Efficiency Valuation Organization. This protocol is consistent with Option A - Retrofit Isolation: Key Parameter Measurement described in the IPMVP, as a number of key parameters are measured (VFD current, VFD %speed and OAT). The use of default fan performance curves is consistent with this option. Regression Reference Guide, This protocol uses regression techniques to fit a linear equation to the measurements of true power and current for the compressor and condenser to extrapolate savings to temperatures beyond those observed in the trend logging period. The application of these regression techniques is consistent with the BPA guide. 7. TYPICAL COST OF APPLYING THIS PROTOCOL Shown below is an estimate of typical cost of applying this protocol. Item Hours $ / Hour Rental Total Cost Labor Practitioner Travel 3 127 381 Scheduling 1 105 105 Facility Operator Interview 1 127 127 Site Inspection 1 127 127 Electrical Measurements 2 127 254 Install/Remove Current Logger 2 127 254 Savings Estimate 4 105 508 QC Review 1 165 165 Travel 2 90 180 Electrical Measurements 2 90 180 Electrician 4 Portland Energy Conservation Inc Item Hours $ / Hour Rental Total Total Cost $2,281 Portland Energy Conservation Inc 5