IE202 * Midterm Study Set

advertisement

Instructor: Assoc. Prof. Oya KARAŞAN

Teaching Assisstant : Seçil Sözüer

IE202- Recitation 1

Fall 2013-2014

October 10, 2013

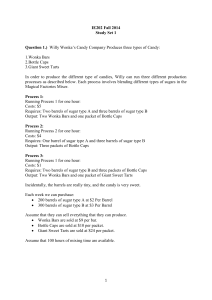

Question 1.) Willy Wonka’s Candy Company Produces three types of Candy :

1.Wonka Bars

2.Bottle Caps

3.Giant Sweet Tarts

In order to produce the different type of candies, Willy can run three different production

processes as described below. Each process involves blending different types of sugars in

the Magical Factories Mixer.

Process 1:

Running Process 1 for one hour:

Costs: $5

Requires: Two barrels of sugar type A and three barrels of sugar type B

Output: Two Wonka Bars and one packet of Bottle Caps

Process 2:

Running Process 2 for one hour:

Costs: $4

Requires: One barrel of sugar type A and three barrels of sugar type B

Output: Three packets of Bottle Caps

Process 3:

Running Process 1 for one hour:

Costs: $1

Requires: Two barrels of sugar type B and three packets of Bottle Caps

Output: Two Wonka Bars and one packet of Giant Sweet Tarts

Incidentally, the barrels are really tiny, and the candy is very sweet.

Each week we can purchase:

200 barrels of sugar type A at $2 Per Barrel

300 barrels of sugar type B at $3 Per Barrel

Assume that they can sell everything that they can produce.

Wonka Bars are sold at $9 per bar.

Bottle Caps are sold at $10 per packet.

Giant Sweet Tarts are sold at $24 per packet.

Assume that 100 hours of mixing time are available.

a. Formulate an LP whose solution will maximize Willy Wonka’s Profits.

b. Assume that instead of having 200 barrels of sugar type A and 300 barrels of sugar

type B available that you can order a total of 500 Barrels. Show how to modify your

LP formulation in Part A to account for this revised problem.

c. Suppose that instead of selling the three candies separately, they can only be sold as

part of a box consisting of one Wonka Bar, two packets of Bottle Caps, and one pack of

Giant Sweet Tarts. Each Wonka Box sells for $54. Modify your LP formulation in part A

to model this new scenario.

Question 2) In the planning of the monthly production for the next six months a

company must, in each month, operate either a normal shift or an extended shift (if it

produces at all). A normal shift costs £100,000 per month and can produce up to 5,000

units per month. An extended shift costs £180,000 per month and can produce up to

7,500 units per month. Note here that, for either type of shift, the cost incurred is fixed by

a union guarantee agreement and so is independent of the amount produced.

It is estimated that changing from a normal shift in one month to an extended shift in the

next month costs an extra £15,000. No extra cost is incurred in changing from an

extended shift in one month to a normal shift in the next month.

The cost of holding stock is estimated to be £2 per unit per month (based on the stock

held at the end of each month) and the initial stock is 3,000 units (produced by a normal

shift). The amount in stock at the end of month 6 should be at least 2,000 units. The

demand for the company's product in each of the next six months is estimated to be as

shown below:

Month

Demand

1

6,000

2

6,500

3

7,500

4

7,000

5

6,000

6

6,000

Production constraints are such that if the company produces anything in a particular

month it must produce at least 2,000 units. If the company wants a production plan for

the next six months that avoids stockouts, formulate their problem as an integer program.

Question 3) A large department store has decided to stay open for business on a

continuous 24 hour basis. The store manager has divided the 24-hour day into six equal

4-hour periods and determined the following minimum personnel requirement for each

period:

Store personnel can report for work at the beginning of any of the above time periods and

will work for 8 consecutive hours. The store manager wants to know the minimum

number of employees to begin work at each 4-hour segment to minimize the total number

of employees. Formulate an integer linear program modeling this problem instance.

Question 4) Esra Cosmetics (EC) produces perfume, which requires chemical and labor.

Two production processes are available: Process 1 transforms 1 unit of labor and 2 units

of chemicals into 3 cl of high quality perfume. Process 2 transforms 2 units of labor and 3

units of chemicals into 7 cl of low quality perfume. It costs EC 3 TL to purchase one unit

of labor and 2 TL to purchase one unit of chemicals. Each month, up to 2000 units of

labor and 3500 units of chemicals can be purchased. One cl of high quality perfume sells

for 5 TL and one cl of low quality perfume sells for 3 TL. The monthly demand for high

quality perfume is 1000cl and that for low quality perfume is 1800cl.

a) If the quantity of high quality perfume is more than its corresponding demand, EC can

use this excess production to meet the demand for low quality perfume. In such a case,

EC can only charge the sales price of low quality perfume. On the other hand, the

demand of high quality perfume can only be met by producing high quality perfume.

Formulate a linear programming problem that maximizes the total profit of EC while

meeting the demand and production requirements.

b) Assume that there is a 3rd process that can transform 1 cl of low quality perfume to 1

cl of high quality perfume using 0.4 units of labor and 0.3 units of chemicals. Formulate a

linear programming problem that maximizes the total profit of EC while meeting the

demand and production requirements. (For this part, please ignore the demand

substitution specified in part a).

Question 5. Consider the problem of locating a new machine to an existing layout

consisting of four machines.

These machines are located at the following x1 and x2 coordinates: (3, 1), (0, -3), (-2, 2),

and (1, 4).

Let the coordinates of the new machine be (x1, x2). Formulate the problem of finding an

optimal

location as a linear program for each of the following cases:

a. The sum of the distances from the new machine to the four machines is minimized.

Use the street distance: for example, the distance from (x1, x2) to the first machine

located at (3, 1) is

|x1 - 3|+|x2 - 1|.

b. Because of various amounts of flow between the new machine and the existing

machines, reformulate the problem where the sum of the weighted distances is

minimized, where the weights corresponding to the four machines are 6, 4, 7, and 2,

respectively.

c. In order to avoid congestion, suppose that the new machine must be located in the

square {(x1, x2) : -1 ≤ x1 ≤ 2, 0 ≤ x2 ≤ 1}. Formulate parts (a) and (b) with this added

restriction.

d. Suppose that the new machine must be located so that its distance from the first

machine does not exceed 2. Formulate the problem with this added restriction.

Question 6. For a telephone survey, a marketing research group needs to contact at least

150 wives, 120 husbands, 100 single adult males, and 110 single adult females. It costs

$2 to make a daytime call and (because of higher labor costs) $5 to make an evening call.

The table below lists the results that can be expected. For example, 30% of all daytime

calls are answered by a wife, and 15% of all evening calls are answered by a single male.

Because of limited staff, at most half of all phone calls can be evening calls.

Person Responding

Wife

Husband

Single Male

Single Female

None

Percentage of Daytime

Calls

30

10

10

10

40

Percentage of Evening Calls

30

30

15

20

5

Ignore the integer constraints and assume that everything is deterministic. Formulate a

linear program to minimize the cost of completing the survey.

Question 7. A production manager is planning the scheduling of three products on 4

machines. Each product can be manufactured on each of the machines. The unit

production cost (in $) are summarized.

PRODUCT

1

2

3

MACHINE

2

4

7

10

1

4

6

12

3

5

5

8

4

7

6

11

The time (in hours) required to produce each unit product on each of the machines is

summarized.

MACHINE

PRODUCT

1

2

3

1

0.3

0.2

0.8

2

0.25

0.3

0.6

3

0.2

0.2

0.6

4

0.2

0.25

0.5

Suppose that 4000, 5000, and 3000 units of the products are required, and that the

available machine hours are 1500, 1200, 1500, and 2000 respectively. Formulate the

scheduling problem as a linear program.