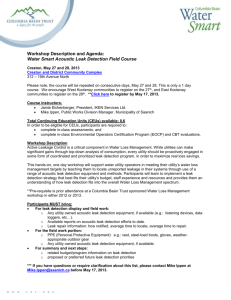

4.2 - Survey Zone Leak Inspection Log Template

advertisement

Organization Logo Here SURVEY ZONE LEAK INSPECTION LOG Equipment Label [Add columns as needed for each compressor] Date/Time Run Hours Load Hours Motor Starts Regulator Hours Output PSI Inspection Date Leak Tag # Zone/Area Inspected Leak Type Line Pressure Line Size Line Temperature General Leak Size or dBµV CFM Leak Cost Usage Reduction Suggestions General Comments Equipment Label: List a recognizable title for supply equipment being tracked. Date/Time: List the date and time when supply equipment data was documented. Run Hours: List the number of run hours between the inspection periods (month, quarter, etc.) for the supply equipment. Load Hours: List the number of hours the equipment was under a load between the inspection periods (month, quarter, etc.) for the supply equipment. Motor Starts: List how many times the equipment was started between the inspection periods (month, quarter, etc.) for the supply equipment. Regulator Hours: List the number of hours documented on the regulator between the inspection periods (month, quarter, etc.) for the supply equipment. Output PSI: List the current PSI of compressed air being produced by the supply equipment. Inspection Date: List the date on which the survey zone inspection was performed or the leak was found. Leak Tag #: List the number of leak tag attached or to be attached, if applicable. Survey Zone Leak Inspection Log - Template ■ PB1.4 Return to TOC 1 of 2 Organization Logo Here Zone/Area Inspected: Describe the general location and area being inspected (for example: mapped leak survey zone, production line, department, room, etc.) Leak Type: List what is leaking (for example: compressed air, steam, water, vacuum, product, waste, etc.). Line Pressure: List the operating pressure of the line that is leaking. Line Size: List the size of the line that is leaking. Line Temperature: List the temperature of the line that is leaking. Measure the temperature from the bare piping surface if no temperature gauge installed; do not measure from surface of any insulation. General Leak Size or dBµV: Describe the leak size (for example, pinhole, 1/32”, 1/8”, etc.) or decibel reading from ultrasonic detector. Alternately, prioritize the leak size or dBµV as high, medium, low. CFM: List the reading from the mass flow sensor or the reading that is calculated from ultrasonic detector or appendix data on the line that is leaking. Leak Cost: Calculate the approximate cost of the leak using the method identified in the procedure. Survey Zone Leak Inspection Log - Template ■ PB1.4 Return to TOC 2 of 2