4-2011 digital

advertisement

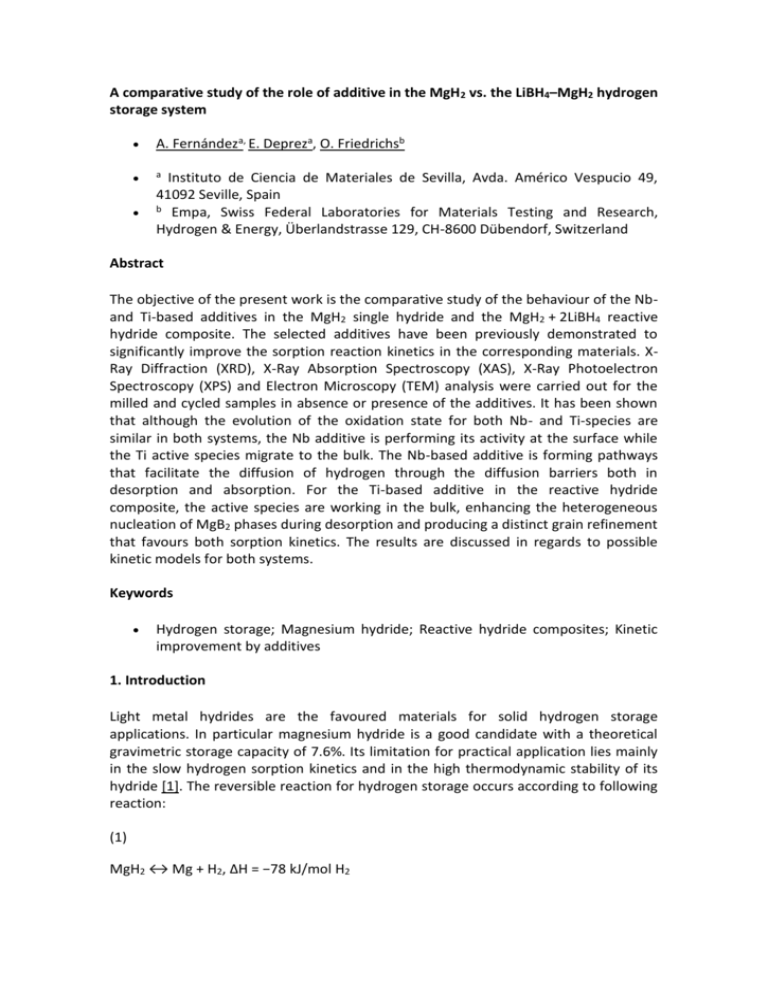

A comparative study of the role of additive in the MgH2 vs. the LiBH4–MgH2 hydrogen storage system A. Fernándeza, E. Depreza, O. Friedrichsb a Instituto de Ciencia de Materiales de Sevilla, Avda. Américo Vespucio 49, 41092 Seville, Spain b Empa, Swiss Federal Laboratories for Materials Testing and Research, Hydrogen & Energy, Überlandstrasse 129, CH-8600 Dübendorf, Switzerland Abstract The objective of the present work is the comparative study of the behaviour of the Nband Ti-based additives in the MgH2 single hydride and the MgH2 + 2LiBH4 reactive hydride composite. The selected additives have been previously demonstrated to significantly improve the sorption reaction kinetics in the corresponding materials. XRay Diffraction (XRD), X-Ray Absorption Spectroscopy (XAS), X-Ray Photoelectron Spectroscopy (XPS) and Electron Microscopy (TEM) analysis were carried out for the milled and cycled samples in absence or presence of the additives. It has been shown that although the evolution of the oxidation state for both Nb- and Ti-species are similar in both systems, the Nb additive is performing its activity at the surface while the Ti active species migrate to the bulk. The Nb-based additive is forming pathways that facilitate the diffusion of hydrogen through the diffusion barriers both in desorption and absorption. For the Ti-based additive in the reactive hydride composite, the active species are working in the bulk, enhancing the heterogeneous nucleation of MgB2 phases during desorption and producing a distinct grain refinement that favours both sorption kinetics. The results are discussed in regards to possible kinetic models for both systems. Keywords Hydrogen storage; Magnesium hydride; Reactive hydride composites; Kinetic improvement by additives 1. Introduction Light metal hydrides are the favoured materials for solid hydrogen storage applications. In particular magnesium hydride is a good candidate with a theoretical gravimetric storage capacity of 7.6%. Its limitation for practical application lies mainly in the slow hydrogen sorption kinetics and in the high thermodynamic stability of its hydride [1]. The reversible reaction for hydrogen storage occurs according to following reaction: (1) MgH2 ↔ Mg + H2, ΔH = −78 kJ/mol H2 Major progress toward technical application has been achieved by using magnesium hydride in nanocrystalline form obtained by mechanical milling [2] and by using transition-metal oxides during the milling process as additives [3], [4], [5] and [6]. This has led to big improvements in the hydrogen sorption kinetics. In particular, Nb 2O5 has been shown to behave as one of the best additives [5], [6], [7] and [8] at the present time. More recently, Vajo et al. [9] and [10] and Barkhordarian et al. [11] and [12] introduced the concept of reactive hydride composite (RHC) combining MgH 2 and borohydrides. As a representative example the reversible system with LiBH4 operates according to the following reaction: (2) 2LiBH4 + MgH2 ↔ 2LiH + MgB2 + 4H2, ΔH = −46 kJ/mol H2 In this system the chemical reaction between the two hydrides lowers the overall reaction enthalpy while the gravimetric hydrogen storage capacity remains high (10.5 wt%). However, although the reaction enthalpy is lowered, desorption and absorption processes occur at high temperatures with a relatively slow two step kinetic [13] and [14]. A significant improvement can be also observed in this system upon the addition of transition-metal-based additives. In particular, Ti-isopropoxide has been shown to behave as one of the best additives [13], [14], [15] and [16] at the present time. In this optimized system working with Ti-based additives at temperatures above the melting point of LiBH4, hydrogen storage capacities of around 8 wt% have been repetitively found during several cycles [16]. Reaction (2) has been determined to extensively occurring by X-ray diffraction analysis. Interesting new results have been recently reported [17] and [18] in which the LiBH4 + MgH2 RHC system has been activated by high energy ball milling at liquid nitrogen temperature with addition of graphite. In these systems operation was possible at temperatures below the melting point of LiBH4 although re-hydriding is mainly due to MgH2. Therefore cycling at this operation temperature is dominated by MgH2 and limited H2 storage capacity was found upon cycling. The presented study has been therefore carried out at high temperature conditions were the concept and operation of the RHC strategy by formation of MgB2 can be fulfilled for the purpose of our investigations. Several works have elucidated the role of the additives in the individual systems. Chemical and microstructural effects have been proposed as the origin of kinetic improvement. For pure MgH2 both Nb metal and Nb2O5 have been investigated [7], [19] and [20]. The formation of ternary Nb-Mg-oxide phases upon milling and heating has been proposed to be the key point for kinetic improvement [5], [6], [21] and [22]. In fact these phases are formed at the grain boundaries and migrate to the surface of Mg/MgH2 grains opening pathways for hydrogen diffusion [5] and [6]. The formation of short-lived metastable Nb-hydride phases was also proposed to improve kinetics for hydrogen absorption and desorption inside the gateways during hydrogen diffusion [23] and [24]. For the RHC system based on the MgH2–LiBH4 couple, several additives based on Ti have been studied including TiCl3, TiF3 and Ti-isopropoxide [13], [14], [25], [26], [27] and [28]. Particularly for the Ti-isopropoxide additive, it was proposed the formation of dispersed TiB2 phases that favours the heterogeneous nucleation of the MgB2 phases during desorption [15], [29] and [30]. In this work both systems, single hydride (SH) and RHC, will be compared to understand the effect of each additive. The chemical state and changes during the reaction as well as the microstructural distribution of the additives are investigated and compared. Analogies and differences will be correlated with the actual proposed kinetic models for the hydrogen sorption kinetics in both systems. It will be shown how the adequate additive is operating for each system according to the corresponding kinetic model. 2. Experimental 2.1. Samples preparation For the RHC system the initial microcrystalline powders, LiBH4 (95% purity) and MgH2 (98% purity, the rest being Mg) and the titanium isopropoxide (99.995% purity) were purchased from Alfa Aesar. MgH2 powder used in the MgH2/Nb2O5 system was purchased from Goldschmidt AG with a purity of 95% (the rest being Mg). As milling additive Nb2O5 micropowder was purchased from Sigma Aldrich with purity higher than 99.99%. Both samples (SH and RHC) were prepared by high energy ball milling which is the most common procedure used to activate the hydride materials for hydrogen storage. Samples of 2LiBH4 + MgH2 composites were prepared in a Spex 8000 mixer mill using a ball (steel) to powder ratio of 10:1. The MgH2 was premilled for 5 h before being mixed to LiBH4 (with or without 10 (or 5) mol% Ti-iso) for a further 5 h milling. The MgH2 samples were synthesized in a Fritsch P5 planetary mill also with 10:1 ball to powder ratio. MgH2 was milled for 5 h and additionally milled (with and without 17 (or 10) wt% additive) for an additional milling time of another 5 h. To prepare the samples at different sorption stages, hydrogen cycling was performed using a thermovolumetric Sieverts apparatus designed by Hydro Quebec/HERA Hydrogen Storage System. For samples of 2LiBH4–MgH2, desorption reactions were performed at 400 °C under 5 bar hydrogen (to achieve the RHC effect with formation of MgB2[13] and [29]), whereas the absorption reactions were measured at 350 °C under 50 bar hydrogen. For MgH2 system measurements were performed at 300 °C at 10 bar of hydrogen for absorption and 0.01 bar for desorption. The samples were prepared and handled under continuously purified argon or nitrogen atmosphere in gloveboxes. 2.2. X-ray diffraction For the system 2LiBH4 + MgH2/Ti-iso XRD measurements were done in a powder diffractometer Siemens D5000-D with a goniometer for transmission geometry and carried out with Cu-Kα radiation. The samples were sealed in glass capillaries inside the glovebox. Data acquisition was performed for 2θ angle range of 20–80°. For the system MgH2/Nb2O5 XRD analysis was carried out in a Bruker D8 Advance X-ray diffractometer for all “ex-situ” prepared samples. For “in situ” heating experiments a Phillips X′Pert diffractometer was used operating with Cu-Kα radiation. This diffractometer was equipped with a high temperature chamber, which was evacuated during heating experiments to a vacuum of 1×10 −5 mbar. The applied heating ramp consisted of a first heating to 140 °C followed by an X-ray measurement, and further heating in steps of 25 °C up to the final temperature of 440 °C with measurement after each heating step. A heating rate of 10 °C/min was used in all cases. 2.3. Transmission Electron Microscope TEM analysis and electron diffraction (ED) was performed in a Philips CM200 microscope operating at 200 kV. Samples were diluted into toluene inside the glovebox, dropped onto a copper grid and introduced into the microscope. A vacuum gate valve allowed the sample to be isolated in a pre-chamber for complete evaporation of toluene prior to transfer for analysis. 2.4. X-ray photoelectron spectroscopy For the system 2LiBH4+MgH2/Ti-iso XPS spectra were recorded with an SPECS Phoibos150 electron spectrometer and a Delay Line Detector in the 9 segmented mode, using Al Kα radiation (1486.6 eV) in an ultrahigh vacuum chamber at a base pressure of 6×10−10 mbar. Ti 2p core level XPS spectra were acquired with 20 eV pass energy and 0.5 eV energy step at normal emission take-off angle. The binding energy reference was taken as the main component of the C1s peak at 284.6 eV for a mixture of adventitious carbon. For the system MgH2/Nb2O5, X-ray photoelectron spectroscopy (XPS) was carried out in a VG Escalab 210 spectrometer with a five-channel hemispheric analyzer for photoelectron registration. The data acquisition took place in constant energy analyzer mode with pass energy of 30 eV. The radiation used was Al Kα (1486.6 eV) from a non monochromatic aluminum X-ray source. The binding energy calibration was performed on the Mg2p peak with energy of 51.2 eV corresponding to a MgO or MgH2 phase appearing at this binding energy. Samples were deposited onto adhesive Cu substrates inside the glovebox and transported in N2 atmosphere to the XPS spectrometer. In both systems samples have been introduced in the spectrometers without being exposed to air. 2.5. X-ray absorption spectroscopy XAS measurements for 2LiBH4+MgH2/Ti-iso system have been performed in transmission mode at BM29 beamline at the European Synchrotron Radiation Facility (ESRF, Grenoble, France). The fixed exit monochromator was equipped with two Si(111) crystals and harmonic rejection was achieved by the use of Si double system mirror. Spectra have been collected at Ti K-edge in the energy ranges 4850–6200 eV under vacuum conditions at ambient temperature. TiB2, Ti2O3, TiO2 anatase and TiO samples were purchased from Sigma Aldrich, to be used as a reference for XAS measurements. EXAFS (X-ray Absorption Fine Structure) and XANES (X-ray Absorption Near Edge Structure) data processing has been carried out by the software ATHENA and ARTHEMIS two interactive graphical utility based on the IFFEFIT library of numerical and XAS algorithms. XANES data reduction has been performed subtracting the preedge background and normalizing the edge jump to one. The obtained EXAFS spectra were analyzed by the non-linear least square fit algorithm implemented in ARTHEMIS software using the phase shift φj(k) and backscattering amplitude functions, Fj(k), calculated with the FEFF 6L code. To fit the spectra, the single scattering paths (SS) corresponding to each coordination shell were used. The characterization of MgH2/Nb2O5 samples was performed at beamline ID24 of the European Synchrotron Radiation Facility (ESRF, Grenoble, France) using a setup that combines angle-dispersive XRD and EDXAS. This arrangement enabled in situ measurements during hydrogen sorption cycles. The XAS measurements on the Nb Kedge (18 986 eV) were carried out in transmission mode. Nb2O5, NbO and NbO2 were purchased from Sigma Aldrich to be used as a reference for XANES analysis. These data were collected on a phosphor marked FReLoN2k CCD camera with a readout time of approximately 800 μs and using a time resolution of 0.5 s by averaging 100 spectra of 5 ms each. 3. Results In a first study XRD was carried out for the SH and RHC with and without additives. Fig. 1 shows the data for the samples after milling and after 1 cycle. Main peaks correspond to the hydrides phases: MgH2 and LiBH4. Considering the Scherrer method crystallite sizes could be evaluated and are summarized in Table 1. It is clear that the milling process, with its introduction of defects and grain boundaries, is decreasing strongly the crystallite size as compared to the as received materials. The effect is even more visible in the presence of additives. After one cycle the crystallite size increases strongly in both SH and RHC systems for the MgH2 phase, giving similar values for both systems under repetitive cycling conditions. The presence of the additive is however producing a significant refinement of crystallite size mainly for the LiBH 4 phase after one cycle in the RHC system. The role of milling seems to be very important to achieve a high dispersion of the additives in the samples [16] as similar kinetic where measured in successive cycling. In the case of the Ti-isopropoxide additive in the RHC system (Fig. 1c and d), no indications are obtained from XRD regarding Ti-based phases in both as milled and cycled samples. The only observation is an increase in Mg-oxide phases for the sample 2LiBH4+MgH2/Ti-iso after cycling due to the extra addition of oxygen in the form of Tiisopropoxide. Another technique is needed here to follow the evolution of the Ti-base additive phases. Regarding the additive in the SH sample, the Nb2O5 phase can however be detected in the XRD pattern of the as milled material. The small peaks at 23 to 26 2θ angles correspond to the 2 mol% (17 wt%) content of the additive in this sample. Cycling produces the disappearance of the niobium oxide peaks indicating the reaction and/or dispersion of the additive. New peaks appear now in the regions corresponding to the magnesium oxide phase. This result is expected as we are introducing extra oxygen in the sample through the addition of the additive. However, a close look to the new peaks corresponding to magnesium oxide phases allowed us to detect the formation of ternary Mg–Nb oxide phases in addition to pure Mg-oxide. Fig. 2 shows the evolution of the XRD pattern during the de-hydrogenation of MgH2 with and without additive. The presence of the new phase, identified as a ternary Mg-Nb-oxide is clearly observed in the presence of additive [31]. This results shows the evolution of the additive to the real active species which has been proposed to be a mixed NbMgxOy phase [31]. Fig. 3a and c shows the morphological TEM analysis of both SH and RHC samples as prepared by ball milling in the hydrided state. The MgH2 big particles (0.1–1 μm size) appear composed of nanocrystals of a few tens of nanometers separated by grain boundaries in both samples. Fig. 3b is showing a high resolution TEM image of the pure MgH2 sample after ball milling where nanocrystals of MgH2 can be identified as well as the MgO surface oxidation layer and the grain boundaries. These results are in agreement with the crystallite size reduction determined by the XRD peaks broadening after ball milling. MgH2 particles appear therefore to be bigger than crystallites in the initial as prepared materials for both samples. The selected area electron diffraction pattern in Fig. 3c for the RHC sample also shows the diffuse rings characteristic of MgH2 nanocrystals of a few tens of nanometer in size. In the case of the RHC the MgH 2 grains appear surrounded by LiBH4. The LiBH4 phase has been shown to be very sensible to the electron beam irradiation. Similar morphology has been observed in the presence or absence of the additive for the majority phases (MgH2 and LiBH4). After cycling the crystallite size of MgH2 increases as shown in Fig. 3d for the cycled RHC sample. In fact the effect can be clearly observed with dark particles in the size range of 100 nm appearing now to be single crystals (see also Table 1 and the selected area electron diffraction pattern in Fig. 3d). No information for the phases of the additive was obtained in the reported TEM analysis. Higher resolution facilities, including elemental mapping analysis, may be employed. In addition the Nb phases appear highly dispersed after cycling and the Ti phases were not detected by XRD. To obtain additional data it was necessary to follow Ti and Nb K-edges in the XAS spectra, from which oxidation state and local structure is obtained. EXAFS analysis was also possible in the case of titanium edge for these samples. The shape and edge position of both Nb and Ti K-edges are represented in Fig. 4 for the near edge structure (XANES) region. The features can be interpreted as finger prints being the shift to lower values in the absorption edge correlated with decreasing oxidation states [31] and [32]. Comparison to reference compounds is undertaken. In Fig. 4 can be seen that the Nb2O5 additive changes already during milling to more reduced Nb species in the SH system. The evolution is complete after the first desorption leading to a state more reduced than +4 for Nb in NbO 2 and slightly over +2 for Nb in NbO. Formally it is around +2.5 indicating a superposition of different states [31]. The situation remains stable under further cycling. In the case of the RHC the XANES analysis of Ti additive is very important as the XRD analysis gives no information. Fig. 4 shows the data of the as prepared milled sample together with data for samples desorbed. The results reveal that also in this case irreversible changes in the oxidation state and local structure of the additive occur during the initial stages of the first desorption. The spectrum of the milled sample presents a first pre-edge at 4970 eV and comparable edge absorption position to the fully oxidized Ti(IV). A significant shift to lower energy is observed for the desorbed sample. Additionally the pre-edge observed with the original milled material is strongly decreased. The Ti-species are clearly reduced upon heating although the metallic Ti phase is not reached since the absorption edge is in an intermediate state between the Ti(II) (TiB2 or TiO) and the Ti(III) (Ti2O3) oxidation states. This can be explained by a mixture of different chemical states of Ti after cycling. The EXAFS analysis (see below) will further support the latter hypothesis. The FT data of the EXAFS oscillations at the Ti K-edge for the fully desorbed RHC sample is represented in Fig. 5 in comparison to relevant references. The reduction process from fully oxidized Ti(IV) in the ball milled sample as observed in the XANES region (Fig. 4) can be also detected in the EXAFS data. In the case of FT data it is possible to observe three peaks in the 0.5 to 2.2 Å region. The two first, located at around 1.15 Å and 1.55 Å (without phase shift corrections), correspond to Ti–O bond distances in the first coordination shell of the Ti2O3 reference material. The intensity of these two peaks decreases progressively during first desorption indicating a further reduction process. The third peak located at 1.9 Å (without phase shift correction), corresponds to Ti–B distances in the first coordination shell of TiB2 and is progressively increasing across this process. We therefore propose that the evolution of the Ti-iso additive during desorption is leading to a final state which is mainly a mixture of Ti(III) as Ti2O3 and Ti(II) as TiB2. The presence of remained TiO2 like phase cannot be fully disregarded. Both Nb-based and Ti-based additives start from a fully oxidized state (+5 and +4 respectively). Both evolve to a reduced state to form the actual active species, namely reduced oxides and borides, which remain unchanged upon further cycling. The XAS analysis has shown a similar concept of formation of reduced oxides and borides as active phases for both SH and RHC systems. However, the surface analysis by XPS of the additive phases lead to a different behaviour of the two kinds of additives. According to Fig. 6 in the as prepared samples, Nb is not present at the surface while there is a remarkable Ti signal. After desorption and absorption cycles the reduced Nb species migrate from the bulk to the surface while the Ti compounds are not detected anymore at the sample surface. The XPS analysis is also giving the oxidation of the elements at the surface. The Ti signal after ball milling correspond to an oxidized +4 state in agreement with previous XANES data. In the case of Nb oxidized and partially reduced phases are found also in agreement with the XANES data. 4. Discussion According to the results presented above we propose a view of the microstructure of the SH and RHC samples as prepared after ball milling (see Fig. 7). For the SH system it is expected that the softer MgH2 phase is covering the harder Nb2O5 oxide crystals [33] (no Nb signal detected at the surface by XPS). In the case of the RHC system, and according to TEM results, the LiBH4 phase appears surrounding the MgH2 while the liquid Ti-isopropoxide impregnates the solid and evolves during milling to an amorphous, soft and highly dispersed Ti(IV) phase (Ti signal detected at the surface by XPS). Upon first desorption it has been shown that the reduced Nb species (ternary Mg-Nboxides) migrate to the surface opening pathways that facilitate the diffusion of hydrogen through diffusion barriers (namely Mg hydride and oxide) [6] and [34]. A schematic representation is included in Fig. 7. This situation is in fact in agreement with a contracting volume kinetic model that has been previously proposed for the Mg/MgH2 system [35]. Hydrogen diffuses from the surface to the bulk during charging and from the bulk to the surface during de-charging. For Ti-based additives in complex hydride materials like NaAlH4 (sodium alanate), the formation of active TiAl3 species on the surface has been proposed as the origin of kinetic improvements in the presence of the additive [36]. A contracting volume model is therefore operating at/from the surface also in this case. For the RHC system the first desorption occurs, under the present experimental conditions without additive, in two steps [13]. First desorption of MgH2 occurs and then desorption of LiBH4 starts (due to slower kinetics). The desired coupling of the MgH2 decomposition to the LiBH4 desorption is a reaction that starts at the Mg/MgH2– LiBH4 interface. This reaction is favoured in the presence of the additive by enhancement, at the TiB2 sites, of the heterogeneous nucleation of the MgB2 product during desorption. It should be emphasized here that the LiBH4 is in a liquid state at the operation temperature. Therefore the H2 desorption reaction from LiBH4 and the simultaneous formation of solid MgB2 occurs at the liquid–solid interface. A heterogeneous nucleation kinetic model is therefore proposed for the desorption process in the RHC system [30]. Already in the first step (see Fig. 4 for 1/3 desorbed sample), the Ti-based additive is reduced to highly dispersed TiB2 (and reduced oxides) and migrates to the bulk. This migration should be favoured by the presence of liquid LiBH4. A schematic representation of the microstructure is included in Fig. 7. In fact heterogeneous nucleation of MgB2 was demonstrated to be the limiting step of the reaction rate in the RHC materials [30]. The re-absorption reaction is occurring in one step and needs again the reaction at the interfaces between the two phases LiH and MgB2. Hydrogen needs however also to be diffused from the surface and this process seems to occur with a contracting volume kinetic model [30]. It is clear that additives operate according to the kinetic model playing their role to improve kinetic of the rate limiting step. Crystallographic parameters are very important to determine why an additive is adequate for a certain system. In fact for the SH material the MgO and the NbO reduced oxide present the same NaCl structure with very similar cell volumes and lattice constants. Therefore the formation of mixed Mg-Nb ternary oxides is highly favoured. For the RHC system in order to favour the heterogeneous nucleation of MgB2 it is necessary to have a lattice match with the additive active species. This is in fact the case of TiB2 and other additives like ZrB2[29]. In both cases it is important to achieve a good dispersion of the additive, which favours the formation of active phases in the form of nanoparticles/nanocrystals for improved kinetics [16] and [37]. 5. Conclusions A comparative study has been presented of the evolution and behaviour of additives in both a single hydride (MgH2/Nb2O5) and a reactive hydride composite (2LiBH4 + MgH2/Ti-iso). It has been shown that in both cases the additive evolves from a fully oxidized state (Nb2O5 and TiO2) to a reduced situation with formal oxidation state near +2 by formation of NbMgxOy and TiB2 respectively. This evolution can occur partially during ball milling and is completed after the first desorption leading to a stable situation of the active phases of the additive. These active species, in the form of dispersed nanoparticles, are working for kinetic improvement according to different mechanisms. For the single hydride system a contracting volume mechanism is operating and the additive is favouring the diffusion of hydrogen from the surface to the bulk and from the bulk to the surface. Nb-based species could be detected at the surface by XPS. In the case of the reactive hydride composite, the desorption process is limited by the heterogeneous nucleation of the MgB2 phase. In this case the additive is working at the LiBH4–Mg interfaces in the bulk of the material where TiB2 species act as nucleation sites for the formation of MgB2. Ti-based species could not be detected at the surface by XPS. As the LiBH4 phase is liquid at the operation temperatures the migration of solid TiB2 species to the LiBH4–Mg interface is favoured. An important aspect is that crystallographic parameters are controlling the capacity of each additive to improve kinetics. For the SH system the lattice match of NbO and MgO favours the formation of ternary NbMgxOy phases that migrate to the surface opening pathways for hydrogen diffusion at grain boundaries. For the RHC system the lattice match of TiB2 and MgB2 allows the nanoparticles of titanium boride to act as nucleation sites for the formation of MgB2 in the heterogeneous reaction of LiBH4 with Mg. The adequate additives are therefore adapted to each system. However, much work is needed in order to understand each particular system in detail. Acknowledgements Authors thank the financial support from the European Marie Curie training networks program (HPRN-CT-2002-00208 and MRTN-CT-2006-035366) and the collaboration with the GKSS research centre. The help of the personnel at BM29 and ID24 in ESRF are gratefully acknowledged. Financial support of the Spanish MICINN (CTQ200913440) and the “Junta de Andalucía” is also acknowledged. References 1.- B. Bogdanovic, T.H. Hartwig, B. Spliethoff The development, testing and optimization of energy storage materials based on the MgH2– Mg system Int J Hydrogen Energy, 18 (1993), pp. 575–589 2.- R. Schulz, S. Boily, L. Zaluski, A. Zaluska, P. Tessier, J.O. Stroem-Olsen Nanocrystalline materials for hydrogen storage Inno Met Mater (1995), p. 529 3.- W. Oelerich, T. Klassen, R. Bormann Metal oxides as catalysts for improved hydrogen soprtion in nanocrystalline Mg-based materials J Alloys Compd, 315 (2001), pp. 237–242 4.- G. Liang, J. Huot, S. Boily, A. Van Neste, R. Schulz Catalytic effect of transition metals on hydrogen sorption in nanocrystalline ball milled MgH2– Tm (Tm=Ti, V, Mn, Fe and Ni) systems J Alloys Compd, 292 (1999), pp. 247–252 5.- O. Friedrichs, F. Aguey-Zinsou, J.R. Ares Fernández, J.C. Sánchez-López, A. Justo, T. Klassen et al. MgH2 with Nb2O5 as additive, for hydrogen storage: chemical, structural and kinetic behavior with heating Acta Mater, 54 (2006), pp. 105–110 6.- O. Friedrichs, J.C. Sánchez-López, C. López-Cartés, T. Klassen Bormann, Fernández A. Nb2O5 “Pathway effect’’ on hydrogen sorption in Mg J Phys Chem B, 110 (2006), pp. 7845–7850 7.- G. Barkhordarian, T. Klassen, R. Bormann Fast Hydrogen sorption kinetics of nanocrystalline Mg using Nb2O5 as catalyst Scripta Mater, 49 (2003), pp. 213–217 8.- G. Barkhordarian, T. Klassen, R. Bormann Effect of Nb2O5 content on hydrogen reaction kinetics of Mg J Alloys Compd, 364 (2004), pp. 242–246 9.- J.J. Vajo, S.L. Skeith, F.O. Mertens Reversible storage of hydrogen in Destabilized LiBH4 J Phys Chem B, 109 (2005), pp. 3719–3722 10.- Vajo JJ, Mertens FO, Skeith SL, Balogh MP. Patent pending 2005 Int Pub No 2005/097671 A2. 11.- G. Barkhordarian, T. Klassen, M. Dornheim, R. Bormann Unexpected kinetic effect of MgB2 in reactive hydride composites containing complex borohydrides J Alloys Compd, 440 (2007), pp. L18–L21 12.- Barkhordarian G, Klassen T, Bormann R. Patent pending 2004 German Pub No 102004/061286. 13.- U. Bösenberg, S. Doppiu, L. Mosegaard, G. Barkhordarian, N. Eigen, A. Borgschulte et al. Hydrogen sorption properties of MgH2–LiBH4 composites Acta Mater, 55 (2007), pp. 3951–3958 14.- J.J. Vajo, T.T. Salguero, A.F. Gross, S.L. Skeith, G.L. Olson Thermodynamic destabilization and reaction kinetics in light metal hydride systems J Alloys Compd, 446-447 (2007), pp. 409–414 15.- E. Deprez, M.A. Muñoz-Márquez, M.A. Roldán, C. Prestipino, F.J. Palomares, C. Bonatto Minella et al. Oxidation State and local structure of Ti-based additives in the reactive hydride composite 2LiBH4 + MgH2 J Phys Chem C, 114 (2010), pp. 3309–3317 16.- E. Deprez, A. Justo, T.C. Rojas, C. López-Cartés, C. Bonatto Minella, U. Bösenberg et al. Microstructural study of the LiBH4–MgH2 reactive hydride composite with and without Tiisopropoxide additive Acta Mater, 58 (2010), pp. 5683–5694 17.- X. Wan, T. Markmaitree, W. Osborn, L.L. Shaw Nanoengineering-Enabled solid-state hydrogen Uptake and Release in the LiBH4 Plus MgH2 system J Phys Chem C, 112 (2008), pp. 18232–18243 18.- K. Crosby, L.L. Shaw Dehydriding and re-hydriding properties of high-energy ball milled LiBH4 + MgH2 mixtures Int J Hydrogen Energy, 35 (2010), pp. 7519–7529 19.- J. Huot, J.F. Pelletier, G. Liang, M. Sutton, R. Schulz Structure of nanocomposite metal hydrides J Alloys Compd, 330–332 (2002), pp. 727–731 20.- C. Milanese, A. Girella, S. Garroni, G. Bruni, V. Berbenni, P. Matteazzi et al. Synergetic effect of C (graphite) and Nb2O5 on the H2 sorption properties of the Mg/MgH2 system Int J Hydrogen Energy, 35 (2010), pp. 9027–9037 21.- M. Porcu, A.K. Petford-Long, J.M. Sykes TEM studies of Nb2O5 catalyst in ball-milled MgH2 for hydrogen storage J Alloys Compd, 453 (2008), pp. 341–346 22.- N. Hanada, T. Ichikawa, H. Fujii Catalystic effect of niobium oxide on hydrogen storage properties of mechanically ball milled MgH2 Physica B, 383 (2006), pp. 49–50 23.- J.F. Pelletier, J. Huot, M. Sutton, R. Schulz, A.R. Sandy, L.B. Lurio et al. Hydrogen desorption mechanism in MgH2–Nb nanocomposites J Phys Rev B, 63 (2001), p. 052103 (4pp) 24.- N. Bazanella, R. Checchetto, A. Miotello, C. Sada, P. Mazzoldi, P. Mengucci Hydrogen kinetics in magnesium hydride: on different catalytic effects of niobium Appl Phys Lett, 89 (2006), p. 014101 (3pp) 25.- P. Wang, L. Ma, Z. Fang, X. Kang, P. Wang Improved hydrogen storage property of Li-Mg-B-H system by milling with titanium trifluoride Energy Environ Sci, 2 (2009), pp. 120–123 26.- F.E. Pinkerton, M.S. Martin, G.P. Meisner, M.P. Balogh, J.J. Vajo Phase boundaries and Reverisbility of LiBH4/MgH2 hydrogen storage material J Phys Chem C, 111 (2007), pp. 12881–12885 27.- P. Sridechprasat, Y. Suttisawat, P. Rangsunvigit, B. Kitiyanan, S. Kulprathipanja Catalyzed LiBH4 and MgH2 mixture for hydrogen storage Int J Hydrogen Energy, 36 (1) (2011), pp. 1200–1205 28.- M.-Q. Fana, L.-X. Suna, Y. Zhanga, F. Xua, J. Zhanga, H.-L. Chua The catalytic effect of additive Nb2O5 on the reversible hydrogen storage performances of LiBH4.MgH2 composite Int J Hydrogen Energy, 33 (2008), pp. 74–80 29.- U. Bösenberg, U. Vainio, P.K. Pranzas, J.M. Bellosta von Colbe, G. Goerigk, E. Welter et al. On the chemical state and distribution of Zr- and V-based additives in reactive hydride composites Nanotechnology, 20 (2009), p. 204003 (9pp) 30.- U. Bösenberg, J.W. Kim, D. Gosslar, N. Eigen, T.R. Jensen, J.M. Bellosta von Colbe et al. Role of additives in LiBH4-MgH2 reactive hydride composites for sorption kinetics Acta Mater, 58 (2010), pp. 3381–3389 31.- O. Friedrichs, D. Martínez-Martínez, G. Guilera, J.C. Sánchez-López, A. Fernández In situ energy-dispersive XAS and XRD study of the Superior hydrogen storage system MgH2/Nb2O5 J Phys Chem C, 111 (2007), pp. 10700–10706 32.- N. Hanada, T. Ichikawa, S. Isobe, T. Nakagawa, K. Tokoyoda, T. Honma et al. X-ray absorption spectroscopic study on valence state and local atomic structure of transition metal oxides doped in MgH2 J Phys Chem C, 113 (2009), pp. 13450–13455 33.- K.F. Aguey-Zinsou, J.R. Ares Fernandez, T. Klassen, R. Bormann Effect of Nb2O5 on MgH2 properties during mechanical milling Int J Hydrogen Energy, 32 (2007), pp. 2400–2407 34.- V.P. Zhdanov, A. Krozer, B. Kasemo Kinetics of first-order phase transitions initiated by diffusion of particles from the surface into the bulk J Phys Rev B, 47 (1993), pp. 11044–11048 35.- G. Barkhordarian, T. Klassen, R. Bormann Kinetic investigation of the effect of milling time on the hydrogen sorption reaction of magnesium catalyzed with different Nb2O5 contents J Alloys Compd, 407 (2006), pp. 249–255 36.- C.P. Baldé, H.A. Stil, A.M.J. van der Eerden, K.P. de Jong, J.H. Bitter Active Ti species in TiCl3-doped NaAlH4. Mechanism for catalyst deactivation J Phys Chem C, 111 (2007), pp. 2797–2802 37.- O. Friedrichs, T. Klassen, J.C. Sánchez-López, R. Bormann, A. Fernández Hydrogen sorption improvement of nanocrystalline MgH2 by Nb2O5 nanoparticles Scripta Mater, 54 (2006), pp. 1293–1297 Table 1. Crystallite sizes calculated by Scherrer of MgH2, MgH2/Nb2O5, 2LiBH4+MgH2 and 2LiBH4+MgH2/5Ti-iso after milling and 1 cycle. Peak Samples Crystallites sizes (nm) Samples Crystallites sizes (nm) (200) MgH2 MgH2 as received 56.0 (310) LiBH4 LiBH4 as received 73.5 (200) MgH2 MgH2 milled 12.0 MgH2/Nb2O5 milled 7.6 (200) MgH2 MgH2 – 1 cycle 69.4 MgH2/Nb2O5 – 1 cycle 63.7 (200) MgH2 (310) LiBH4 25.5 2LiBH4+MgH2 milled (200) MgH2 (310) LiBH4 40.8 58.9 2LiBH4+MgH2 – 1 cycle 39.1 2LiBH4+MgH2/5Ti- 9.8 iso milled 24.4 2LiBH4+MgH2/5Ti- 62.0 iso – 1 cycle 19.7 Figure captions Figure 1. XRD pattern after ball milling and one cycle of MgH2 (a), MgH2/17 wt% Nb2O5 (b), 2LiBH4+MgH2 (c) and 2LiBH4+MgH2/5 mol% Ti-iso (d). Peak positions of the references (NbMgxOy, monoclinic Nb2O5, hexagonal Mg, cubic MgO, tetragonal MgH2, hexagonal MgH2, orthorhombic LiBH4 and anatase TiO2) are indicated above. ∗ Indicate the MgH2 (200) and LiBH4 (310) peaks used for calculation of crystallite size in Table 1. Figure 2. XRD pattern of MgH2 and MgH2/17 wt% Nb2O5 as a function of temperature. Positions of MgO and NbMgxOy diffraction peaks are indicated by a dash line. Figure 3. TEM micrographs of MgH2 after ball milling (a) and (b) and 2LiBH4+MgH2 after ball milling (c) and after one cycle (d). The insets in (c) and (d) correspond to the selected area electron diffraction pattern for the big particles with a darker contrast. Figure 4. XANES data at the Nb (a) and Ti K-edge (b) for milled and desorbed samples (with 10 wt% Nb2O5 and 10 mol% Ti-iso respectively for SH and RHC system) as compared to reference materials. Figure 5. Fourier Transform curves of the EXAFS oscillations for 2LiBH4+MgH2/10 mol% Ti-iso milled, 1/3 desorbed and fully desorbed as compared to reference materials (TiB2, TiO2, Ti2O3 and Ti). Figure 6. Ti 2p photoemission peak in 2LiBH4+MgH2/5 mol% Ti-iso after ball milling, desorption and 1 cycle and Nb 3d photoemission peak in MgH2/17 wt% Nb2O5 after milling, 1 cycle and 6 cycles. Figure 7. Scheme of the microstructure of MgH2/Nb2O5 and 2LiBH4+MgH2/Ti-iso. Figure 1 Figure 2 Figure 3 Figure 4 Figure 5 Figure 6 Figure 7